Prefabricated steel structure civil school building

A steel structure and assembly technology, applied in schools, building structures, columns, etc., can solve the problems of long construction period and slow construction process, and achieve the effect of improving efficiency, reducing the use of steel bars, and reducing the time for tying steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0046] This project is a new construction project of Liangzhu Senior High School in Yuhang District. The project described in this invention is a student dormitory building with 6 floors above the ground and a main structure height of 23.57m. The structural system is a steel frame structure, and the seismic fortification category is Class B.

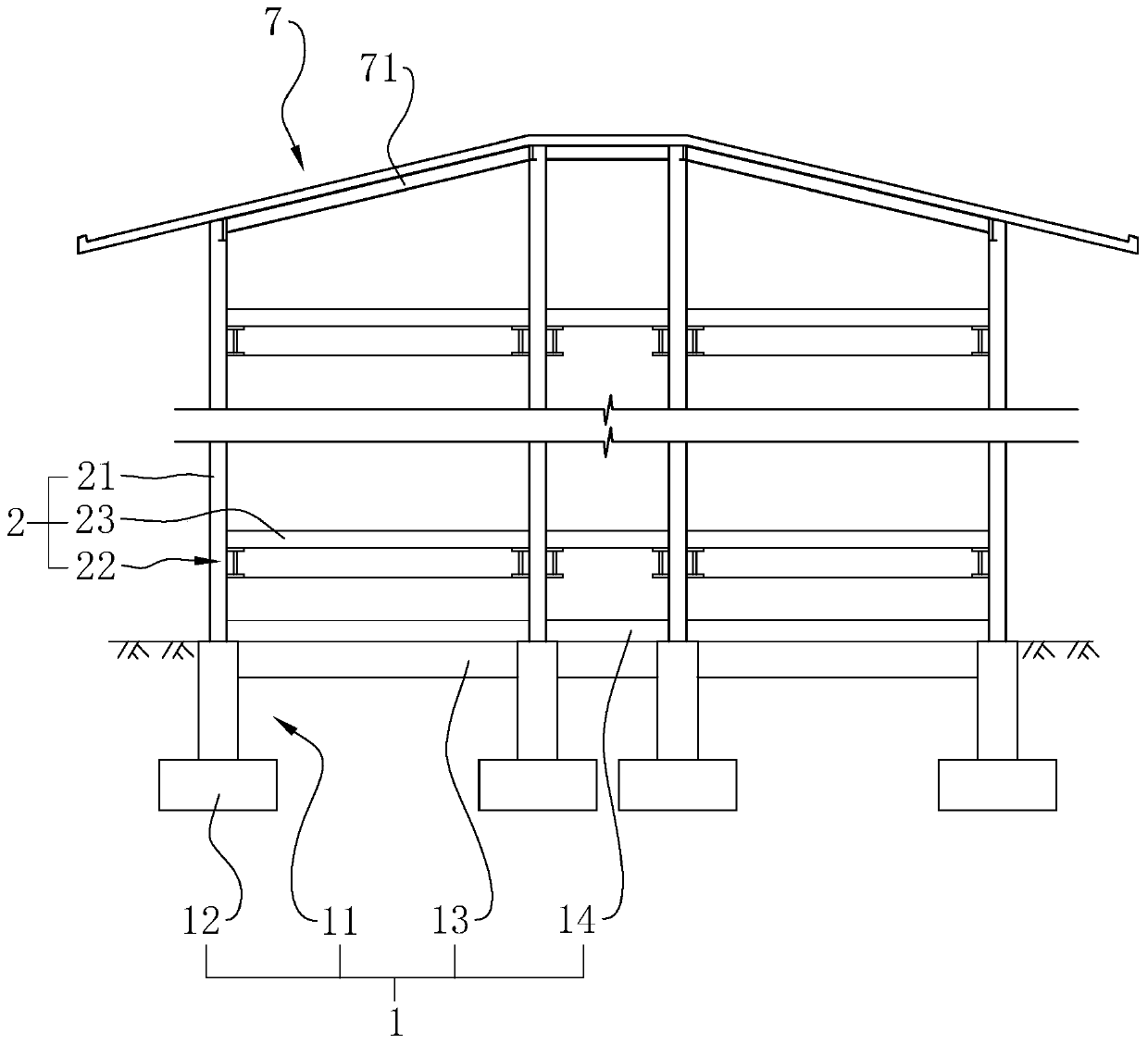

[0047] refer to figure 1 , is a prefabricated steel structure civilian school building disclosed by the present invention, comprising a bottom layer 1, a standard layer 2 and a roof layer 7 arranged sequentially from bottom to top.

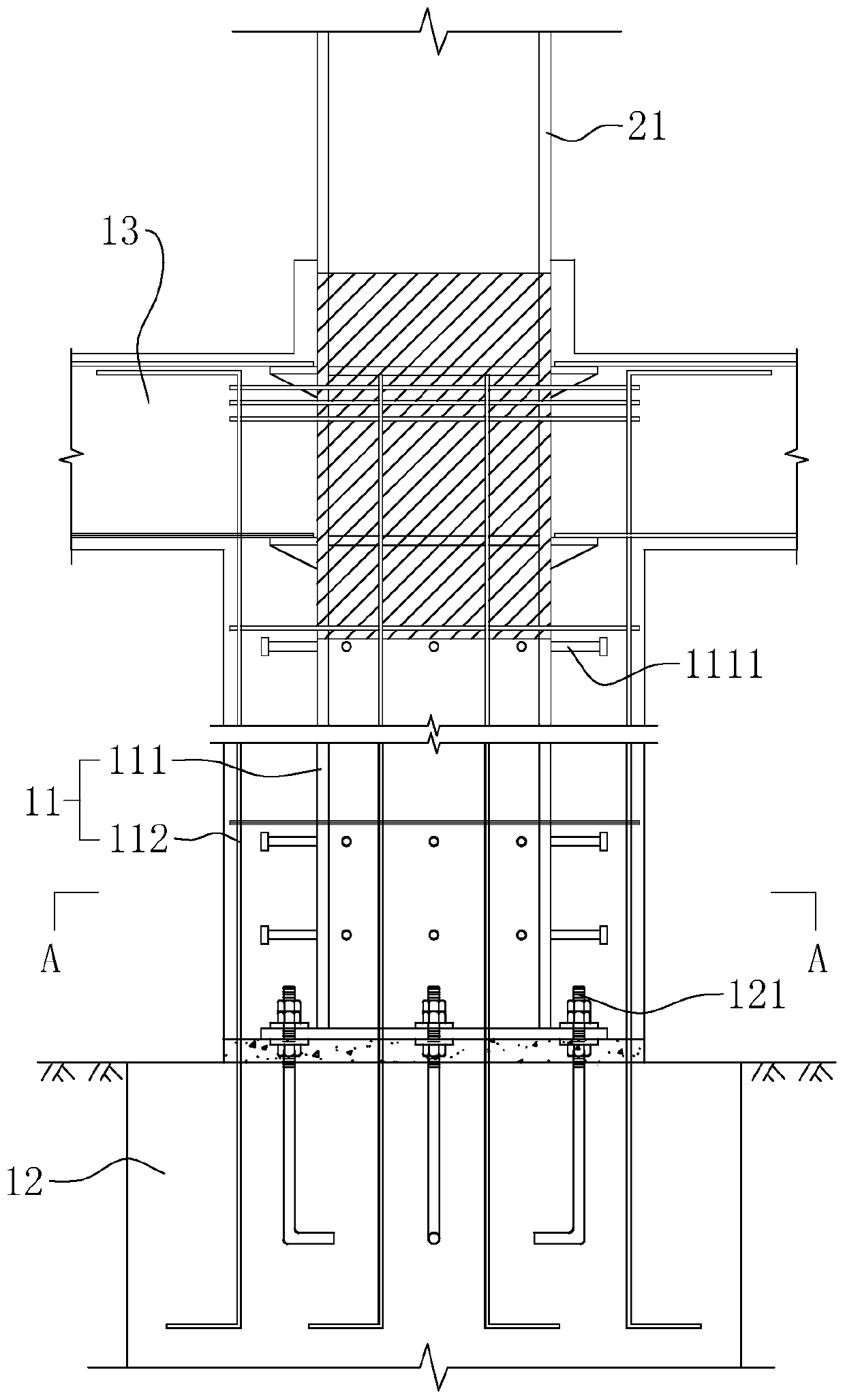

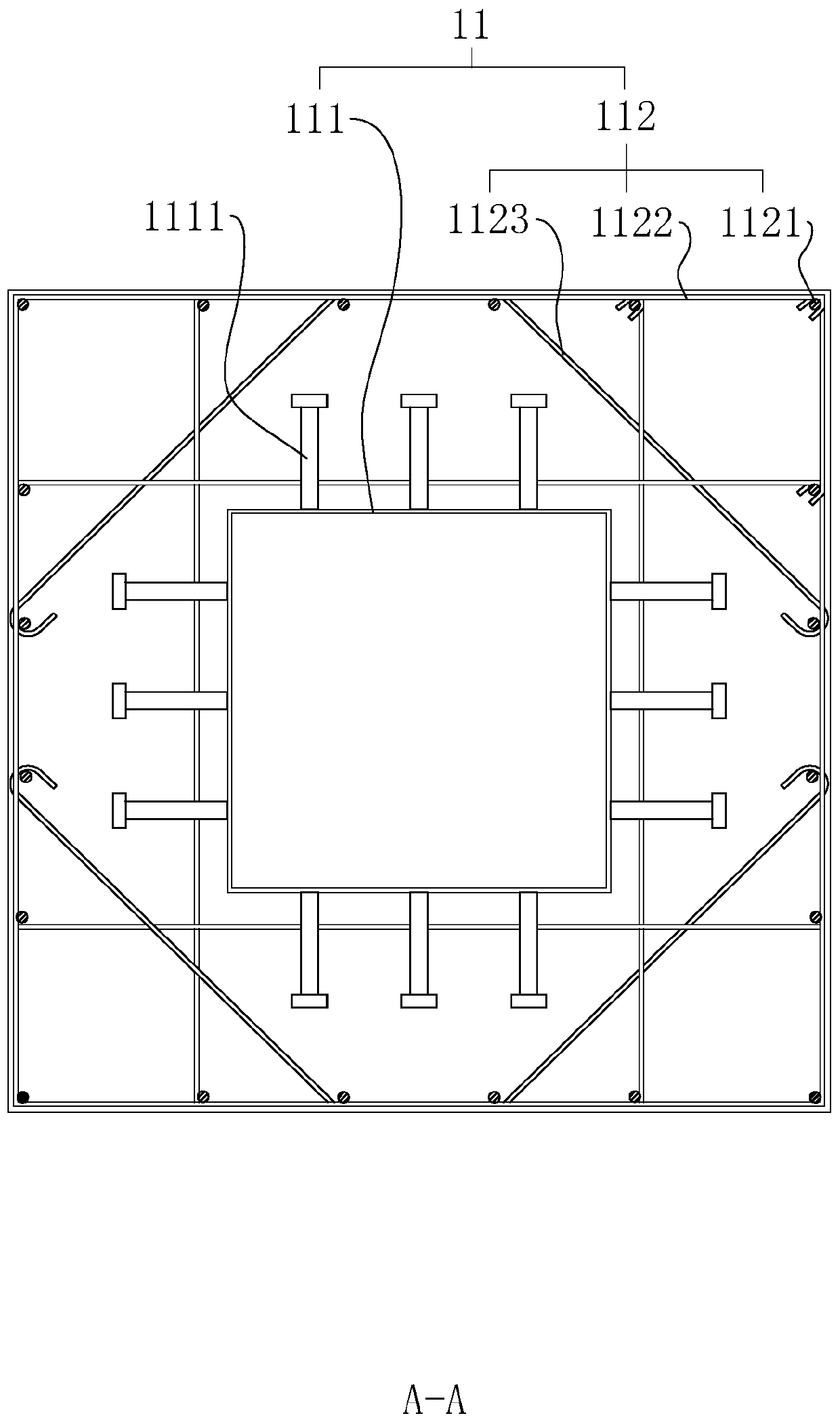

[0048] The ground floor 1 includes a transmission column 11 , a foundation 12 connected to the bottom of the transmission column 11 , a reinforced concrete beam 13 connected between adjacent transmission columns 11 and a bottom plate 14 arranged on the reinforced concrete beam 13 . The fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com