Pipeline submerged-arc welding wire increasing device and wire-increasingwelding technology

A submerged arc welding wire and submerged arc welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of affecting welding quality, excessive molten pool, complex structure, etc., and reduce the temperature and existence time of the molten pool. , to ensure the quality of welding, to prevent the effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

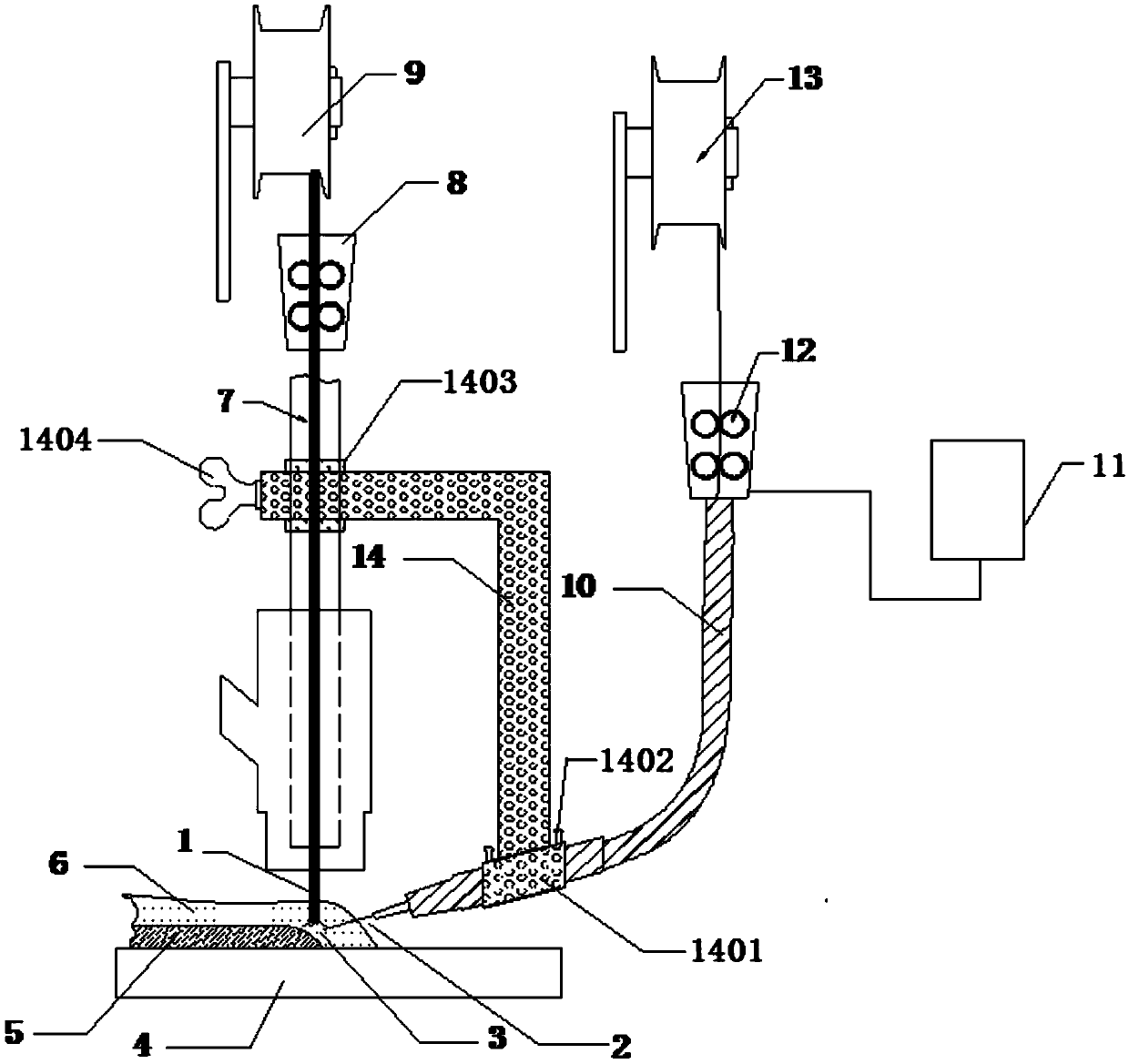

[0042] Such as figure 1 As shown, a pipeline submerged arc welding wire increasing device includes a submerged arc welding wire contact tip 7 of a submerged arc welding machine, and a fixing frame 14 is fixedly arranged on the submerged arc welding wire contact tip 7, and the fixing frame 14 has an L-shaped structure The bottom of the vertical rod of the fixed frame 14 is inclined to set a first connecting sleeve 1401, and the first connecting sleeve 1401 is fixedly provided with a wire increasing guide tube 10, and the increasing wire guiding tube 10 sends the increased welding wire to There are 3 welding arcs formed by submerged arc welding wire 1; The wire mechanism 8 has the same structure; the wire increasing wire feeding mechanism 12 sends the welding wire on the increasing wire feeding plate 13 to the increasing wire guiding tube 10 .

[0043] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com