Low-pressure natural gas/coal-bed gas purifying device

A technology for purifying device and natural gas, which is used in combination devices, gas fuels, chemical instruments and methods, etc., to achieve wide application prospects, increase the resistance formation time, and reduce the rising speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The low-pressure natural gas / coal bed gas purification device of the present invention will be further described in detail with specific embodiments below in conjunction with the accompanying drawings. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

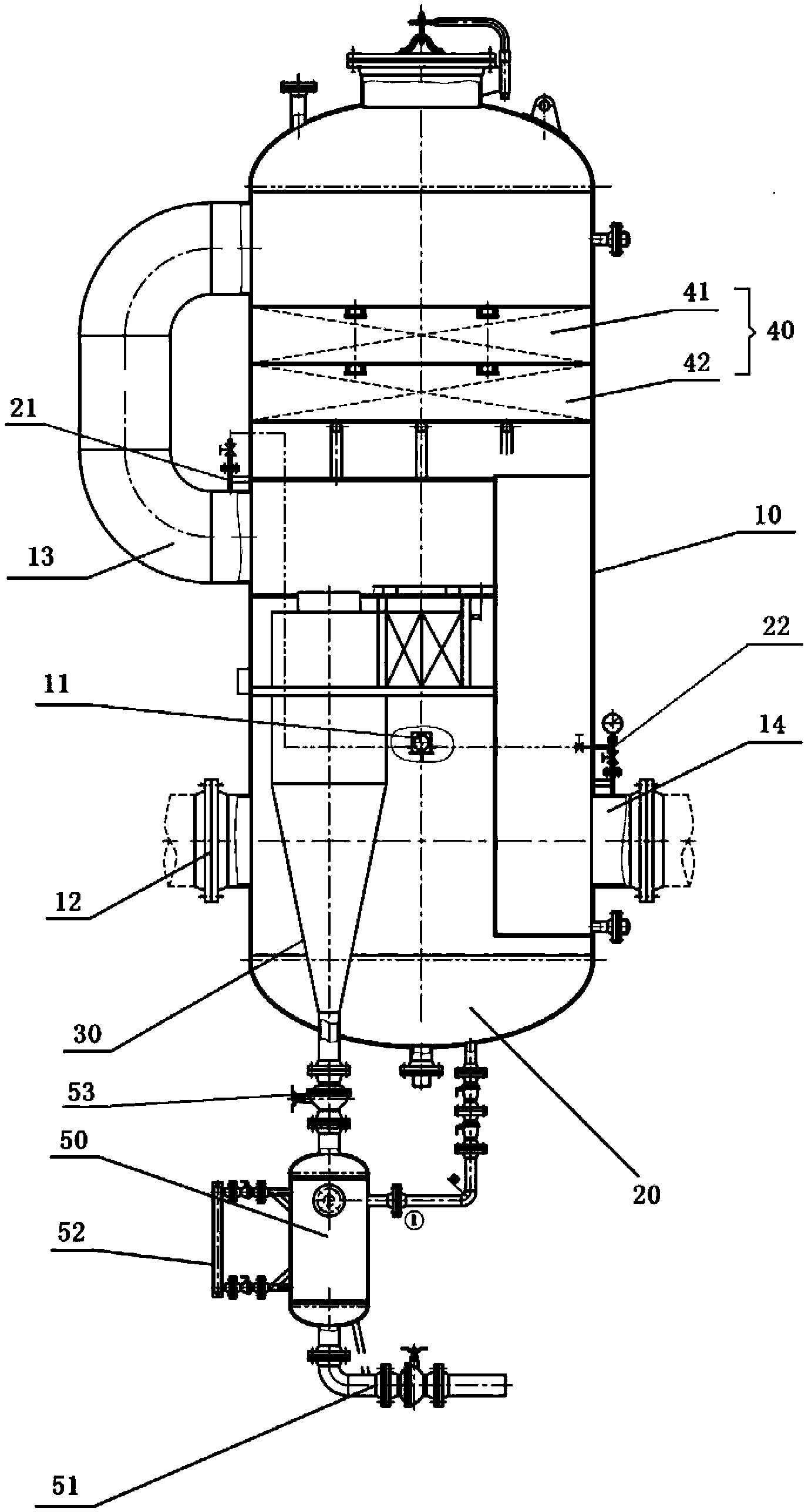

[0027] like figure 1 As shown, the low-pressure natural gas / coal bed methane purification device of the present invention includes a tank body 10 in which a gravity settling chamber 20 , a cyclone separator 30 and a gas filter 40 are sequentially arranged.

[0028] Wherein, the gas filter 40 includes two layers of filter boxes, which are respectively the filter box 1 41 of the upper layer and the filter box 2 42 of the lower floor, and the filter box 1 41 and the filter box 2 42 are filled with hollow Fibers, preferably hollow fibers with 7 to 13 holes. Those skilled in the art can easily understand that although th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com