EDI (Electro-deionization) and electro-catalytic integrated reactor and method for removing nitrate

An electrodeionization and electrocatalysis technology, applied in the field of electrochemistry, can solve problems such as low current utilization, low reaction rate, and reduced current utilization efficiency, and achieve the effects of improving current efficiency, reducing voltage drop, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

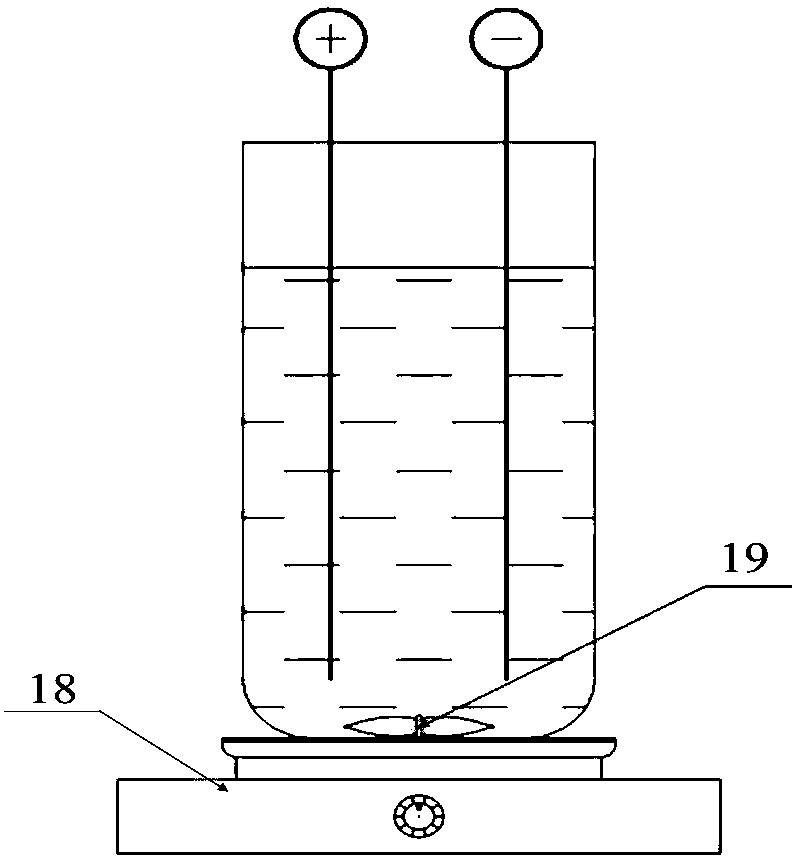

[0084] Wherein the preparation steps of the electrocatalytic cathode electrode 31 include:

[0085] 1) First, a Pd catalyst and a Sn catalyst are loaded on the activated carbon fiber by a multi-step impregnation method to obtain Pd and Sn modified activated carbon fiber;

[0086] ① Boil the strip-shaped ACF in distilled water for more than three hours to fully desorb and regenerate to ensure that there is no impurity on the ACF carrier and that there is enough surface area in direct contact with the metal to ensure the stability of the ACF in contact with the metal and to ensure the stability of the production process. The life of the obtained catalytic electrode is guaranteed. Take it out, rinse it with distilled water, and dry it at 90-115°C for 12 hours.

[0087] ②Preparation of 300mL mass fraction of 5% ethylenediaminetetraacetic acid disodium (EDTANa 2 ) solution, soak the ACF obtained in ① for more than 12 hours to make it fully adsorb EDTANa 2 , and then dried at 90 ...

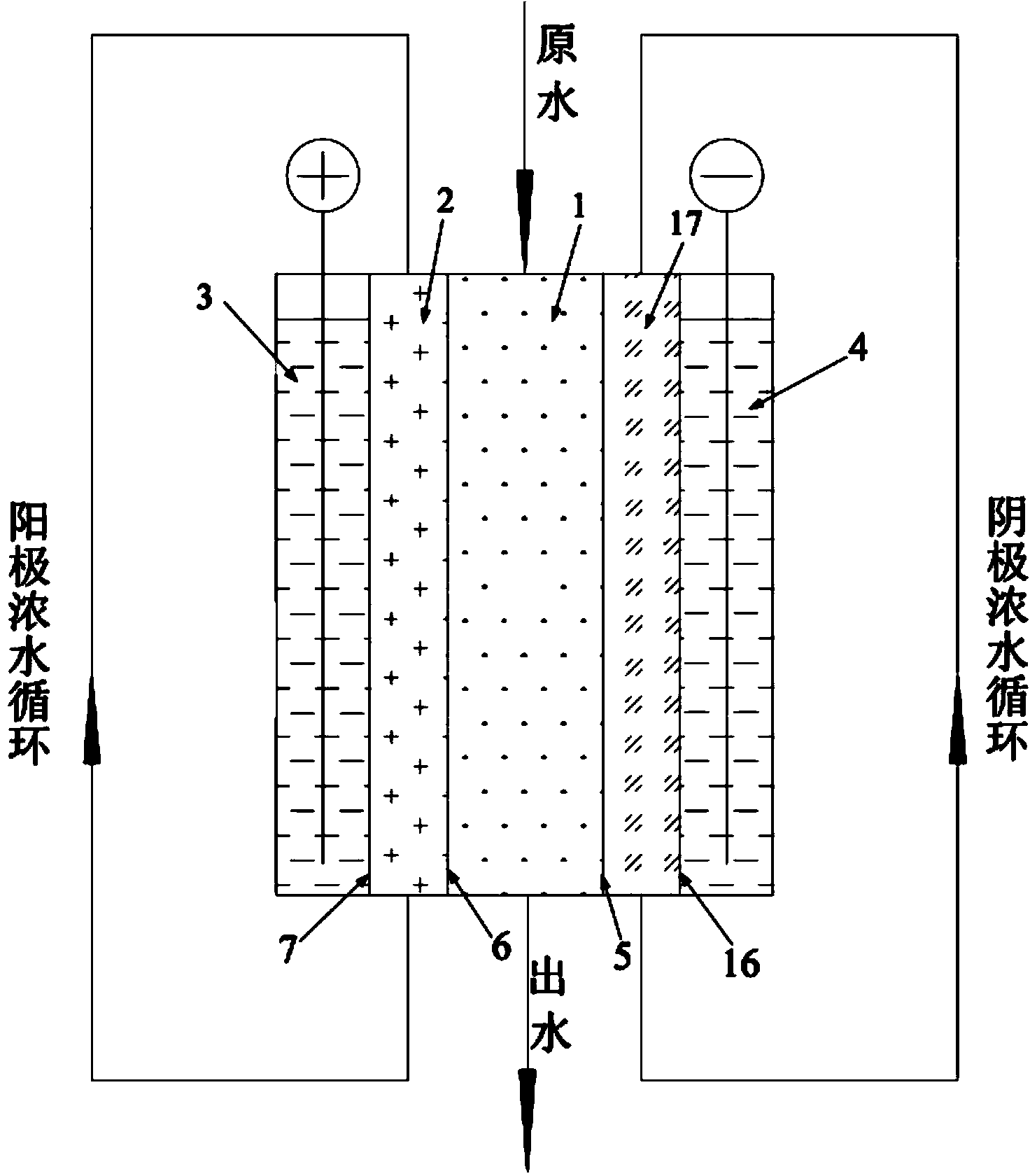

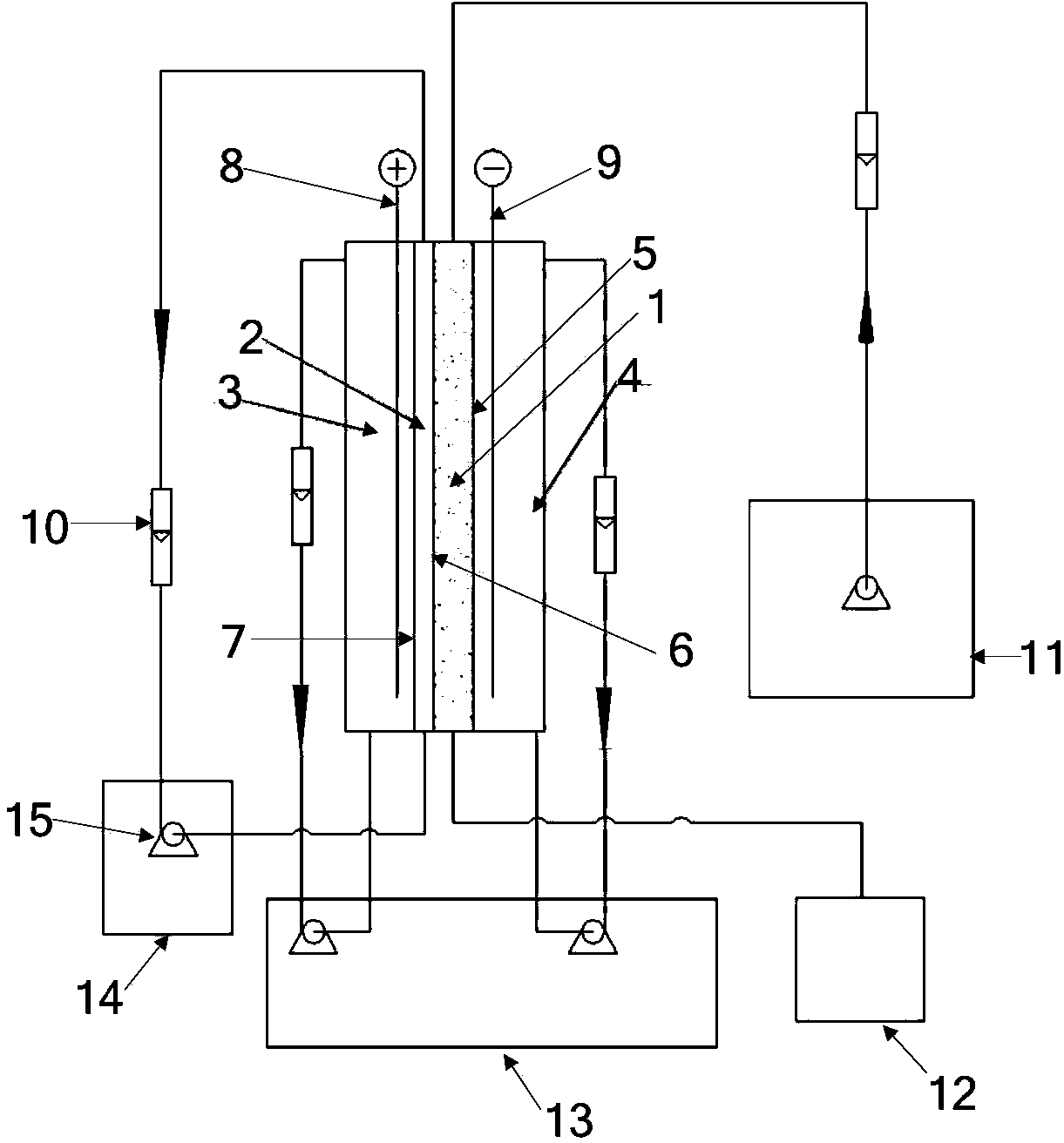

Embodiment 1

[0114] Mix D407 nitrate adsorption resin and D001 macroporous cation exchange resin at a volume ratio of 10:4 and place in fresh water chamber 1, and treat 100mg / L, 6L NaNO 3 solution, EDI runs for 300min, and NaNO is discharged 3 The concentration has been kept below 2mg / L, and the conductivity is 17us / cm, which is close to the standard of pure water. And the NaNO concentrated in the anode concentrated water chamber 3 The concentration is 735mg / L, and the conductivity has exceeded 9999us / cm. After electrocatalytic reduction for 1800min, NO 3 - The concentration has dropped to 110mg / L, Na + and OH - Combined to form NaOH, NaNO 3 The removal amount reached more than 85%.

Embodiment 2

[0116] The reactor handles 90mg / L, 6L of Mg(NO 3 ) 2 solution, EDI runs for 300min, and NaNO is discharged 3 Concentration has been maintained at 1.7mg / L or less. The conductivity is 17us / cm. Close to the standard of pure water. While the concentrated Mg(NO 3 ) 2 The concentration is 677g / L, and the conductivity has reached 8924us / cm. After electrocatalytic reduction for 1800min, NO 3 - The concentration has dropped to 96mg / L, Mg 2+ with OH - Combined to form magnesium hydroxide precipitate. The removal amount reached more than 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com