Anaerobic reactor

An anaerobic reactor and reactor technology, applied in the field of anaerobic reactors, can solve the problems of affecting the activity of microbial methanogens in sludge, the decline of methane production, and the reduction of effective reaction area area, so as to alleviate sludge calcification and Pipeline fouling phenomenon, response to changes in water quality and quantity, and the effect of achieving sludge discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical solutions of the present invention will be further described below according to specific embodiments. The protection scope of the present invention is not limited to the following examples, which are listed for illustrative purposes only and do not limit the present invention in any way.

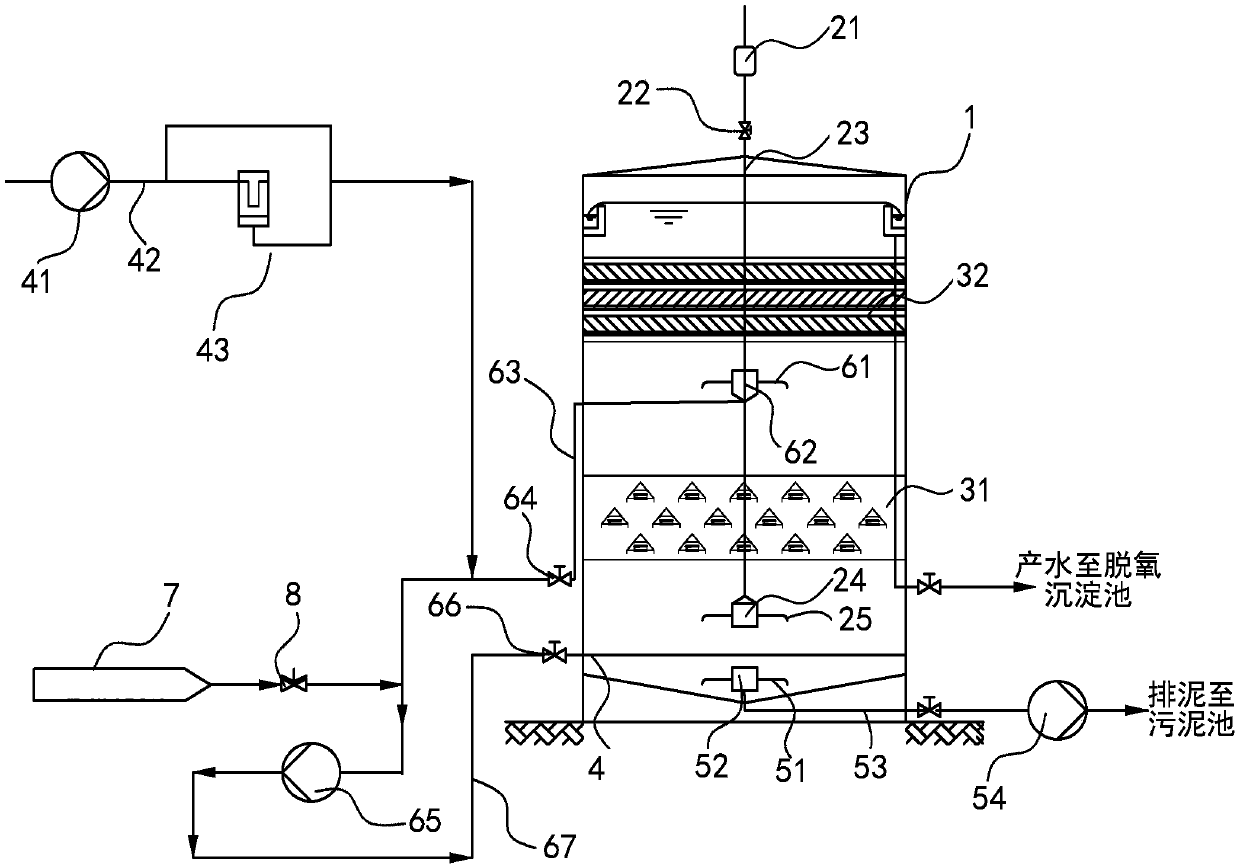

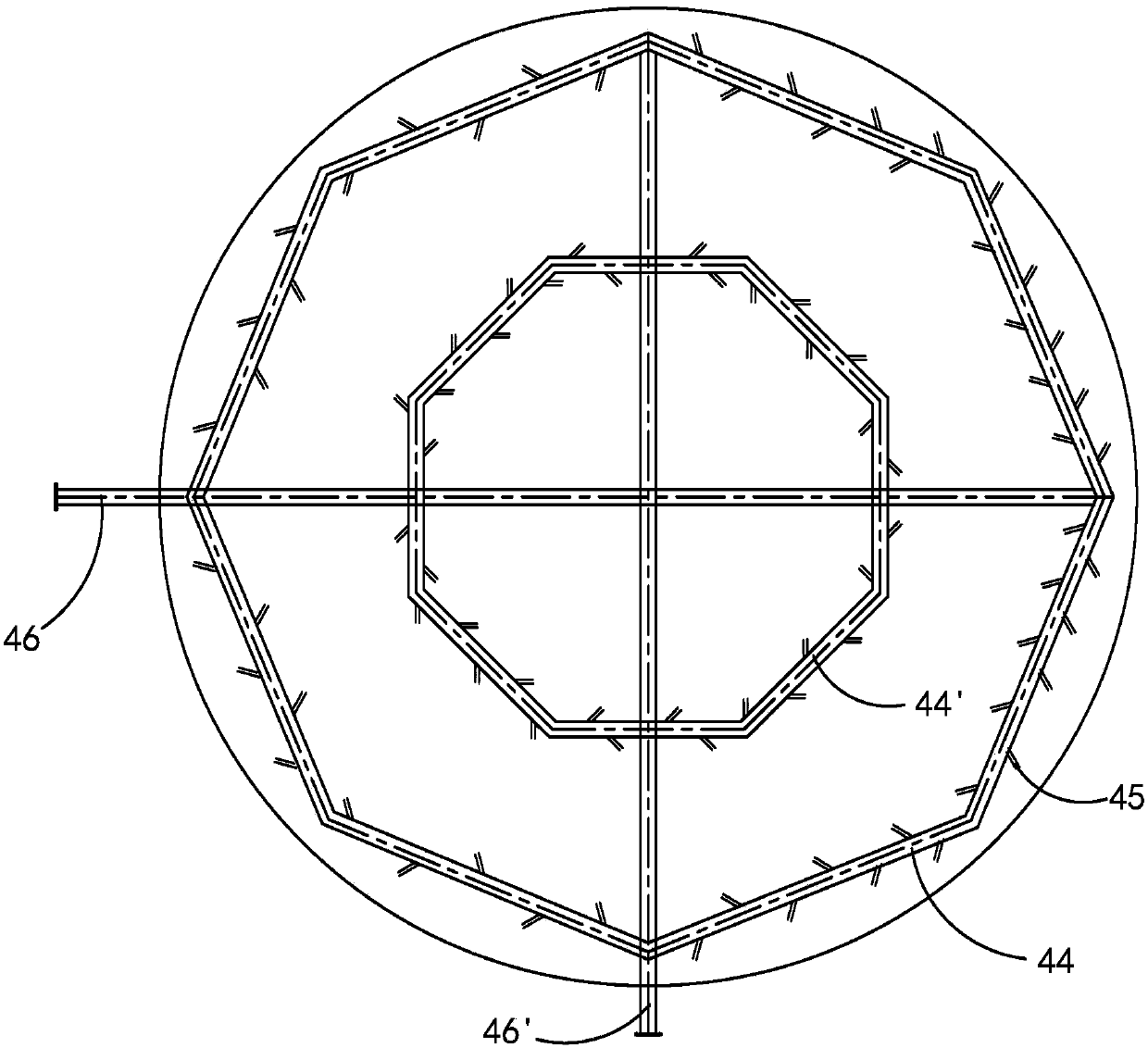

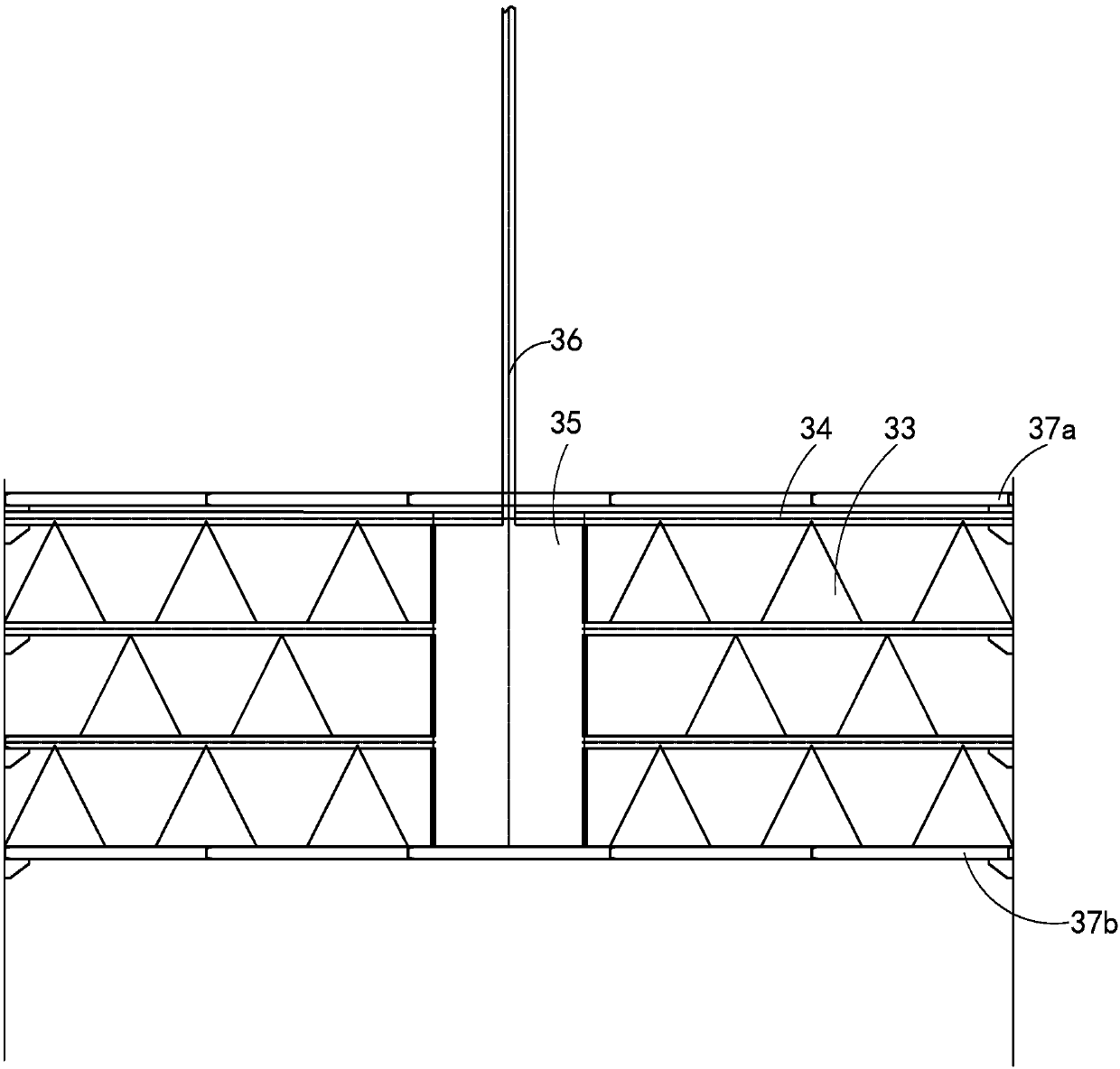

[0070] combine figure 1 , figure 2 , image 3 As shown, the present invention provides an anaerobic reactor, comprising: a reactor tank 1, a gas-liquid separation system, a three-phase separation system, a water distribution system 4 and a sludge discharge system, and the gas-liquid separation system is arranged on the reactor tank body At the top of the reactor, the three-phase separation system is connected to the gas-liquid separation system through the gas header (not shown), and the water distribution system and the sludge discharge system are set at the bottom of the anaerobic reactor.

[0071] The water distribution system includes a water inlet main pipe 42, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com