Central draining construction method of highway tunnel

A technology of expressways and construction methods, applied in drainage, tunnels, tunnel linings, etc., can solve the problems of easy damage of concrete drainage pipes, and achieve the effect of good integrity, safety, high quality and high efficiency, and smooth drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

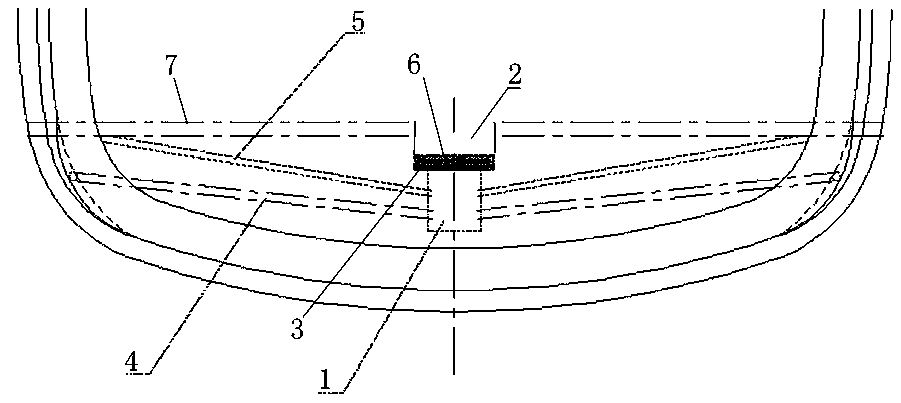

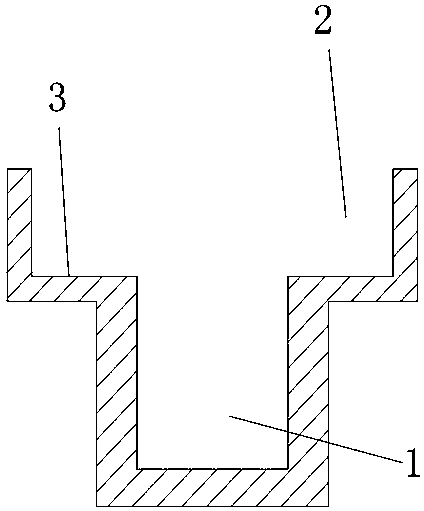

[0010] The construction method for the central drainage of expressway tunnels is realized by the following steps: 1) Constructing a central drainage groove in the inverted arch concrete filling, the central drainage groove is composed of a narrow groove 1 at the bottom, a wide groove 2 at the top and a combination of the two 2) The horizontal drainage pipe 4 of the tunnel and the horizontal water guide pipe 5 of the road extend and connect to the narrow groove 1 at the lower part of the central drainage ditch; 3) Lay a cover plate 6 on the central drainage ditch , both sides of the cover plate 6 are respectively supported on the horizontal support surface 3 on the two side walls of the central drainage ditch; 4) backfill concrete in the wide groove 2 above the cover plate 6 to the concrete filling surface of the inverted arch.

[0011] During specific implementation, in step 1), the construction of the central drainage trench is carried out on the reinforced invert (the tunnel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com