Range hood noise reduction method and device and range hood using device

A hood and noise technology, which is applied in the field of range hood equipment, can solve problems such as excessive noise of hoods, and achieve the effects of improved noise performance indicators, large sound-absorbing surface area, and good noise absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Aiming at the technical problem of too much noise from the hood, this paper lists a specific embodiment to solve the above problem. A noise reduction device for a hood, comprising a covering part 1 covering the air duct system of the hood, the covering part 1 covering the area between the joint between the hood body and the fan and the air outlet of the fan; the covering part 1 and A closed cavity is formed between the fan and the impeller at the air outlet of the hood, and a sound-absorbing material layer is provided on the inner surface of the covering part 1 .

[0032] The cladding structure is easy to install and can absorb the noise scattered from the cladding area to the surroundings. The sound-absorbing material layer is a sound-absorbing wedge.

[0033] Sound-absorbing wedge sound-absorbing mechanism: sound-absorbing structures are generally divided into planar structures and impedance transitional structures. For the original flat-plate structure, according to...

Embodiment 2

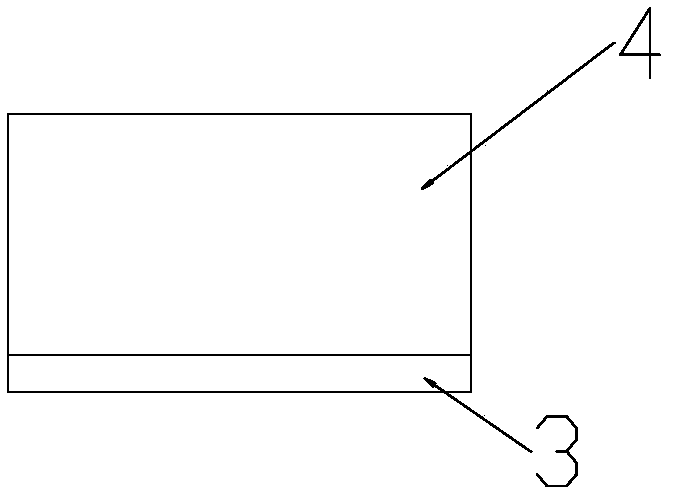

[0035] This embodiment is further limited on the basis of Embodiment 1. The sound-absorbing material layer is a sound-absorbing wedge, and the sound-absorbing wedge is composed of a base 3 and a wedge 4, and the part of the wedge 4 from the top to the base is Cross-sectional area gradient structure. The covering part 1 is a wall structure surrounded by four sides, the lower end of the enclosed space is fixedly connected with the hood body, the upper end of the enclosed space is provided with a cover plate 5, and the cover plate 5 is provided with a through hole matching the air outlet . The inner wall of the cover plate 5 is provided with a sound-absorbing wedge.

[0036] The cross-sectional area of the sound-absorbing wedge belongs to a gradual structure, and due to the protrusion, the contact area between the sound-absorbing material and the sound wave increases. When the wedge unit contacts the sound wave, the sound wave reaches the tip of the sound-absorbing wedge. The...

Embodiment 3

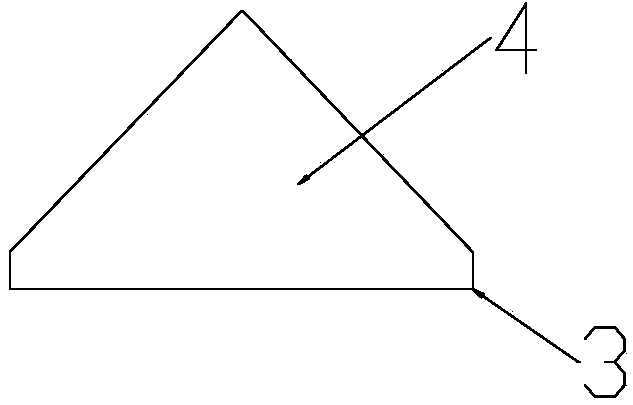

[0038] This embodiment is further defined on the basis of Embodiment 1. The wedge part is a triangular prism with an isosceles triangle bottom surface, the base is square, and the rectangular surface corresponding to the hypotenuse of the triangle of the wedge part is in contact with the base. refer to Figure 1-Figure 3 .

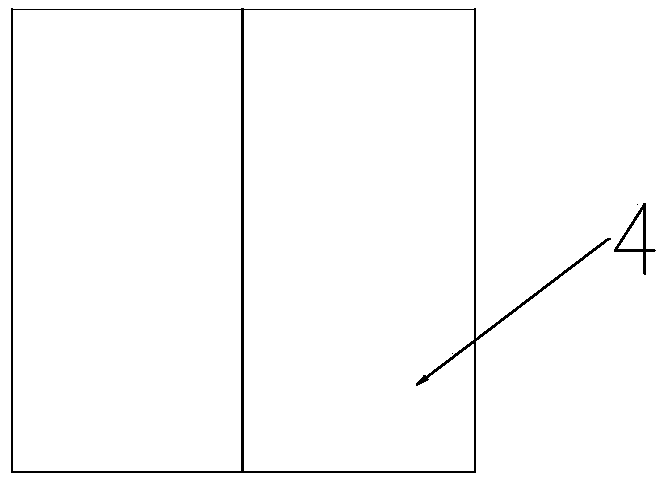

[0039] This embodiment provides an arrangement of sound-absorbing wedges in Embodiment 3, and the wedges are arranged in a staggered array on the inner wall of the covering portion. refer to Figure 5 .

[0040] A comparison example is given here for the staggered array. The sound-absorbing panels arranged in a misplaced arrangement and the sound-absorbing panels arranged in a non-displaced arrangement are placed in front of the noise probe for testing, and the four times of data are summed. The comparison shows that the noise of the staggered arrangement is reduced. The amount of noise reduction is 8.1dBA, and the noise reduction amount of non-disloca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com