Arched ruler

A technology of bow and connecting ruler, applied in the field of bow ruler, can not solve the problems of flange welding perpendicularity and detection of flange flatness, etc., and achieves the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

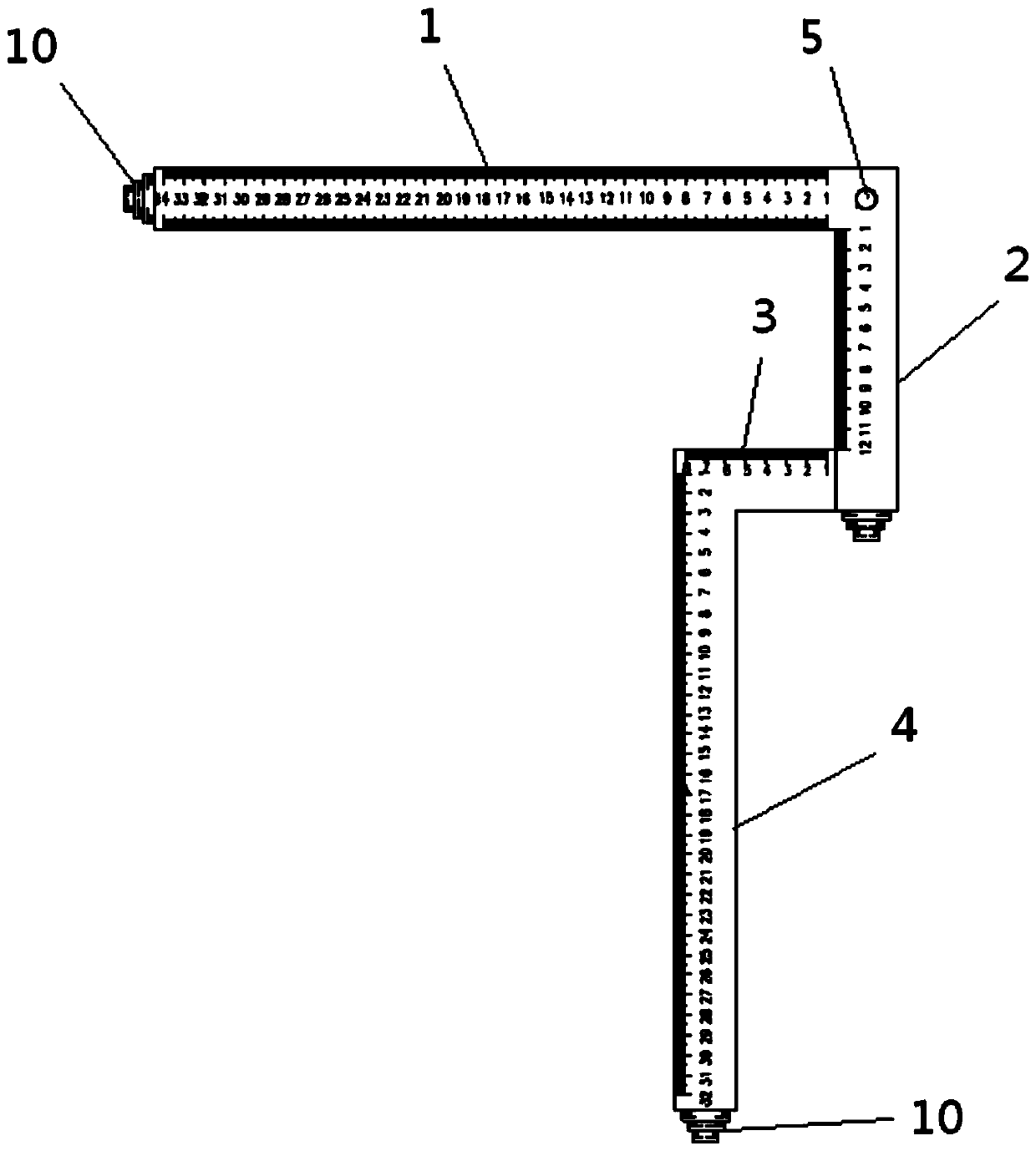

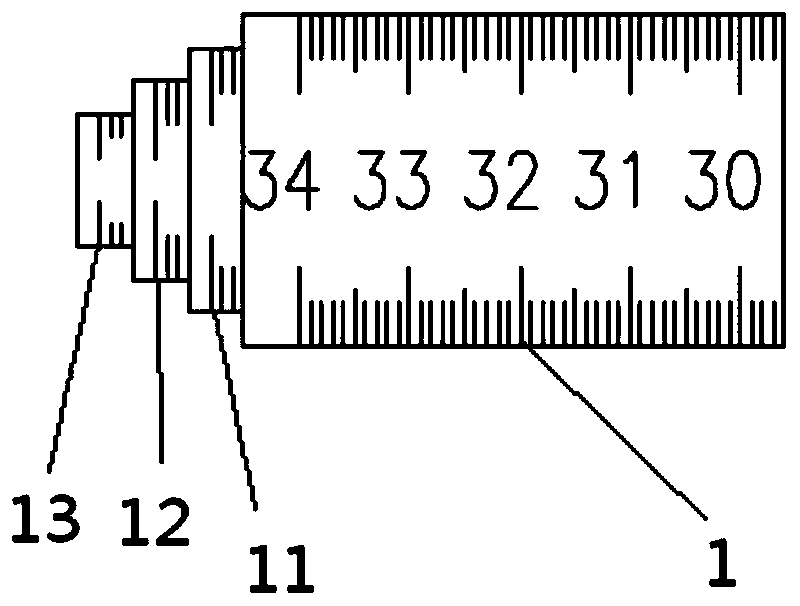

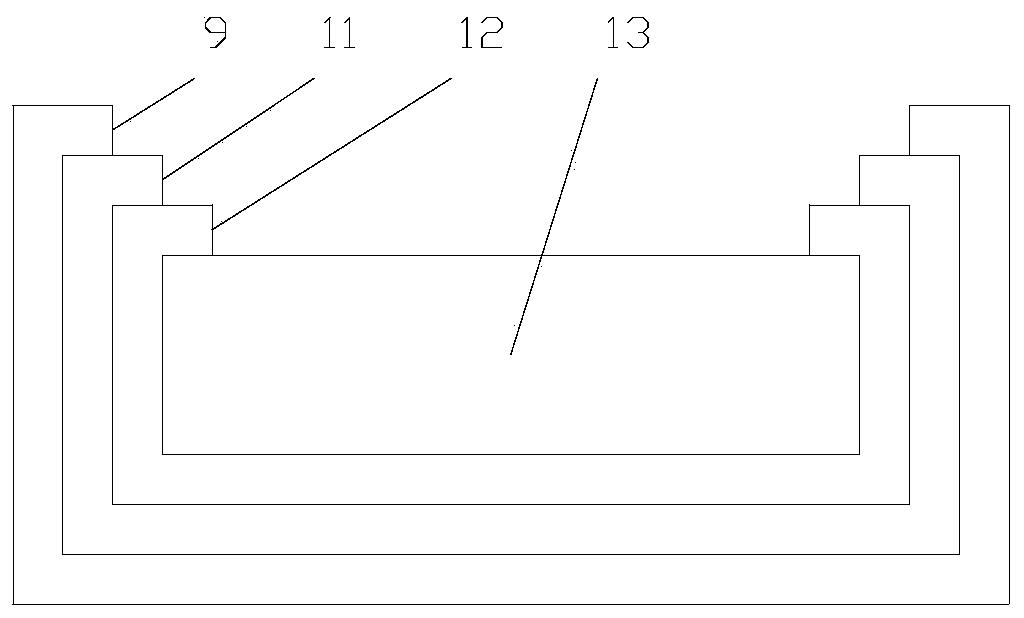

[0021] figure 1 It is a structural schematic diagram of the bow ruler of the present invention, please refer to figure 1 , a bow-shaped ruler, which includes: the same side of the vertical connecting ruler 2 has: a horizontal measuring ruler 1 and a horizontal connecting ruler 3, and the end of the horizontal connecting ruler 3 has a vertical measuring ruler 4. During use, for the structure of the flange 7 welded with the pipeline 6, the horizontal measuring ruler 1 is placed on the upper surface of the flange 7, and the diameter of the flange 7 is larger than that of the pipeline 6. Therefore, through the vertical connecting ruler 2 and the horizontal connecting ruler 3, Make the vertical measuring ruler 4 contact with the side wall of the pipeline 6 to measure the side wall of the pipeline 6 .

[0022] Figure 4 It is a reference diagram of the use state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com