A copper pipe bending machine

A technology of a bending machine and a bending mechanism, which is applied in the directions of feeding devices, manufacturing tools, positioning devices, etc., can solve the problems of time-consuming and laborious manual bending, unfavorable industrial production, and high labor intensity of employees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

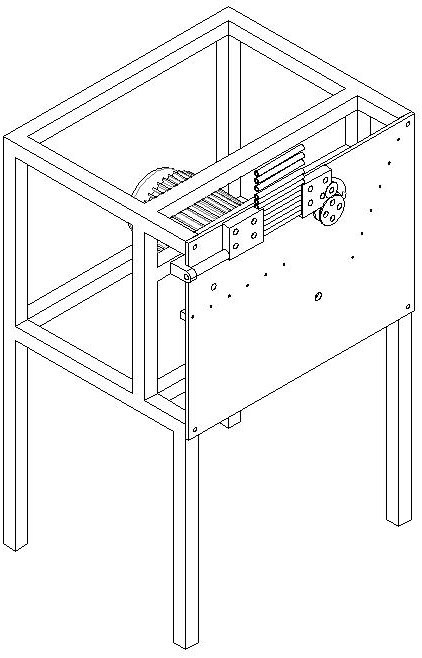

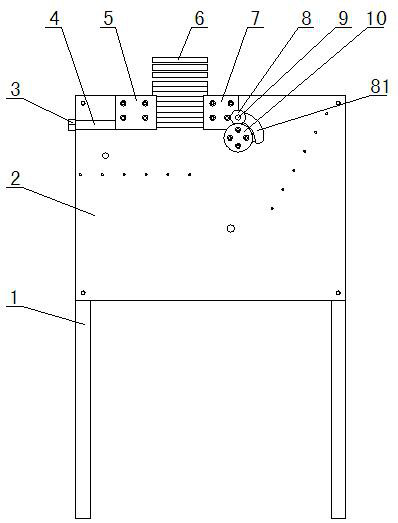

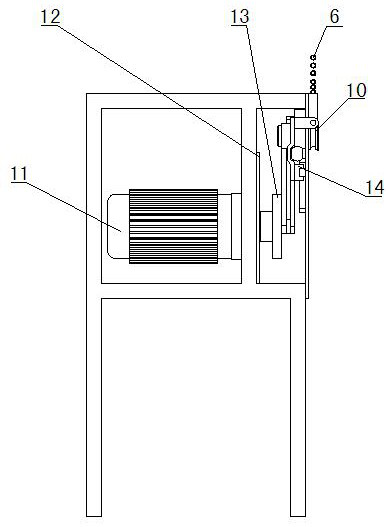

[0029] The present application will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present application and the present application is not limited to the following examples.

[0030] see Figure 1 to Figure 6 , this embodiment includes a frame 1 and a connecting plate 2, and is characterized in that it also includes a feeding mechanism, a bending mechanism, and a power mechanism, and the described feeding mechanism, bending mechanism, and power mechanism are all installed on the frame 1 The power mechanism first drives the feeding mechanism to deliver the processed copper pipe 6 to the bending mechanism through the crankshaft disk 13 in one rotation cycle, and then drives the bending mechanism through the crankshaft disk 13 to press and bend the processed copper pipe 6 to complete the processing work.

[0031] The feeding mechanism includes a feeding linear guide 27, a feeding slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com