Integrated sealed type contact set for railway

A contact group, sealed technology, applied in railway car body components, railway signals, railway signals and safety, etc., can solve the problems of heavy maintenance tasks in the electric service section, equipment running with diseases, and increased contact resistance, and achieves high rotational speed. And the effect of flexible movement, reliable electrical performance and reliable electrical action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

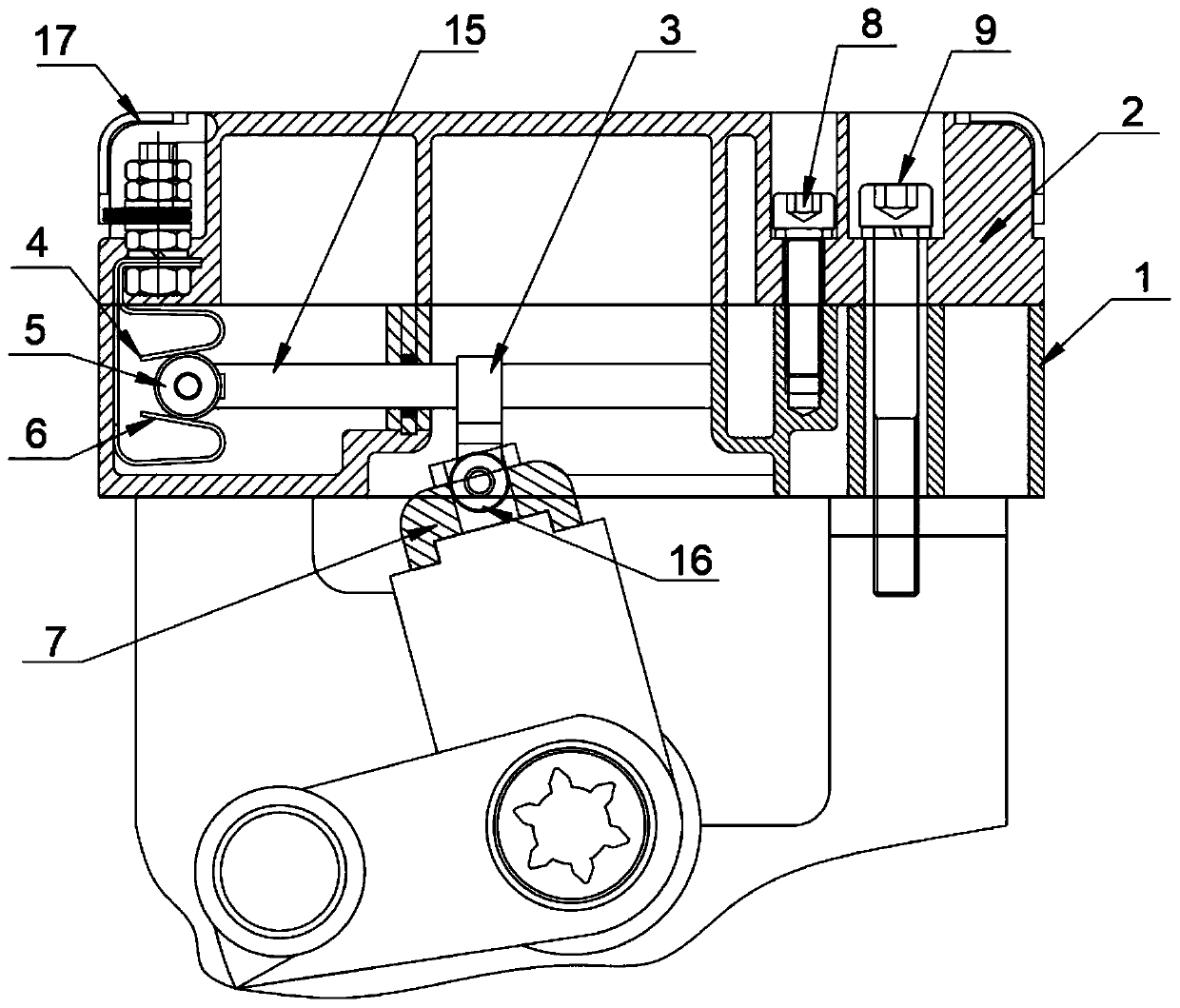

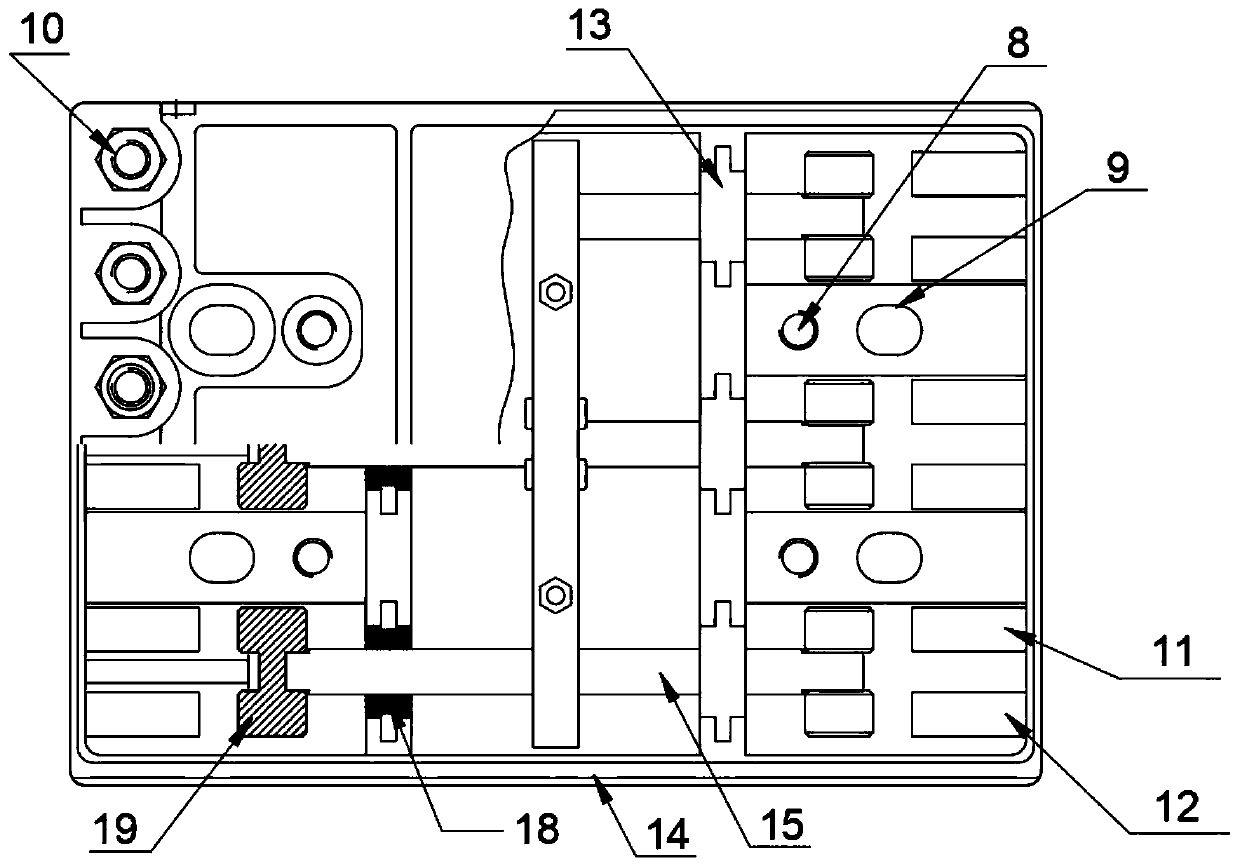

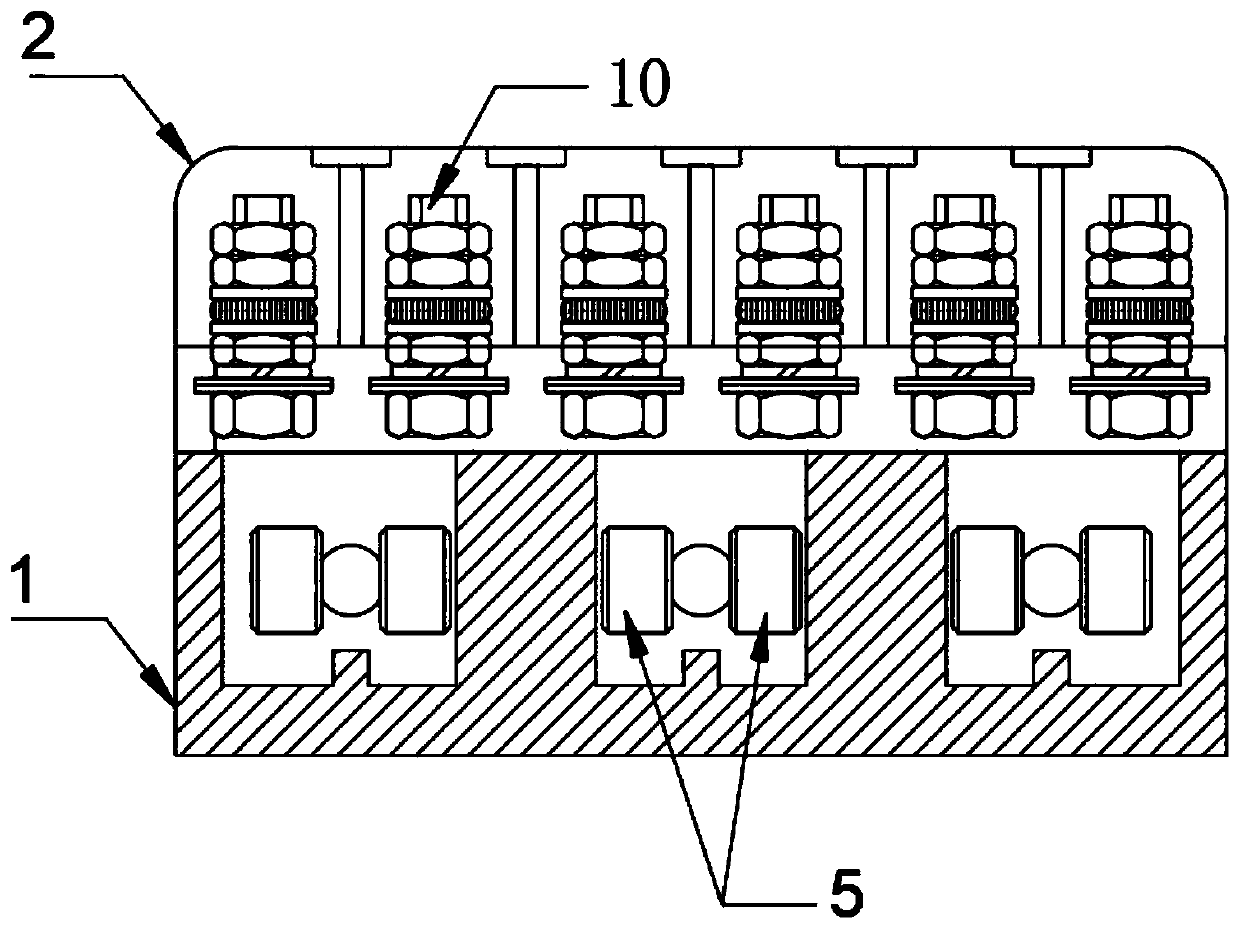

[0022] Such as Figure 1-6 As shown, the present invention provides an integrated sealed contact group for railways, including a bottom case 1, an upper case 2, a central swing body 3, a static point unit, a moving contact 5, a driving block 7, an insulating protective cover 17 and a terminal 10. The bottom shell 1 and the upper shell 2 are fixed together by the fixing bolts 8, and the contact group is installed on the base of the automatic switch through the mounting bolts 9. The upper shell 2 is arranged above the bottom shell 1, so that The upper casing 2 is fixedly connected with the bottom casing 1 through the fixing bolts 8, and the two ends of the top of the upper casing 2 are symmetrically provided with six terminals 10, and the bottom of the terminal 10 is provided with a static point upper plate. 4 and static point lower sheet 6, static point upper sheet 4 and static point lower sheet 6 are combined into static point unit, and described static point unit is positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com