Colored glaze raindrop glaze ceramic firing technology

A raindrop glaze and color glaze technology are applied in the field of color glaze raindrop glaze ceramic firing technology, which can solve the problems of short firing time, waste of raw materials, long time consumption and the like, and achieve the effect of solving the long time consumption of firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

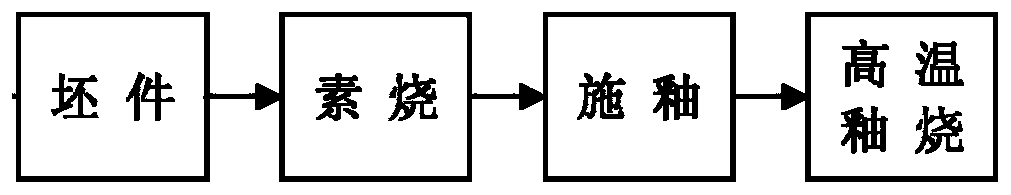

[0025] Step 1: Blank making, making the blank of the required shape by grouting, billet drawing or mechanical forming;

[0026] Step 2: Biscuit firing, after lining the blank, firing at a temperature of 800-1000°C;

[0027] Step 3: Glazing, the blank is glazed once or more;

[0028] Step 4: High-temperature firing, through high-temperature firing at 1250-1300°C.

specific Embodiment 2

[0030] Step 1: Blank making, making the blank of the required shape by grouting, billet drawing or mechanical forming;

[0031] Step 2: biscuit firing, after lining the blank, pass bisque firing at a low temperature of 800-1000°C;

[0032] Step 3: Glazing, glazing the blank once or more times, and glazing firing at a medium temperature at 600-800°C;

[0033] Step 4: High-temperature firing at 1250-1300°C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap