Method for treating waste incineration fly ash

A technology for waste incineration fly ash and raw materials, applied in chemical instruments and methods, improvement of process efficiency, removal of solid waste, etc. The effect of cost reduction, resource utilization and harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

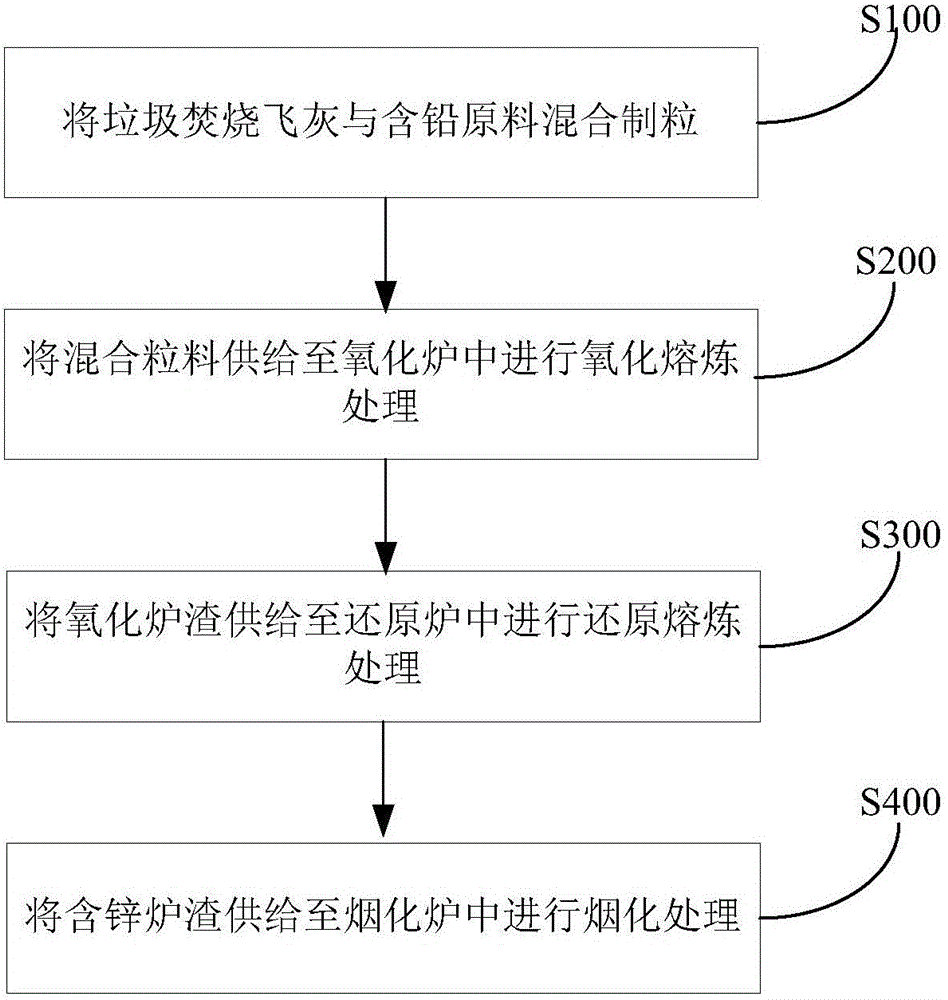

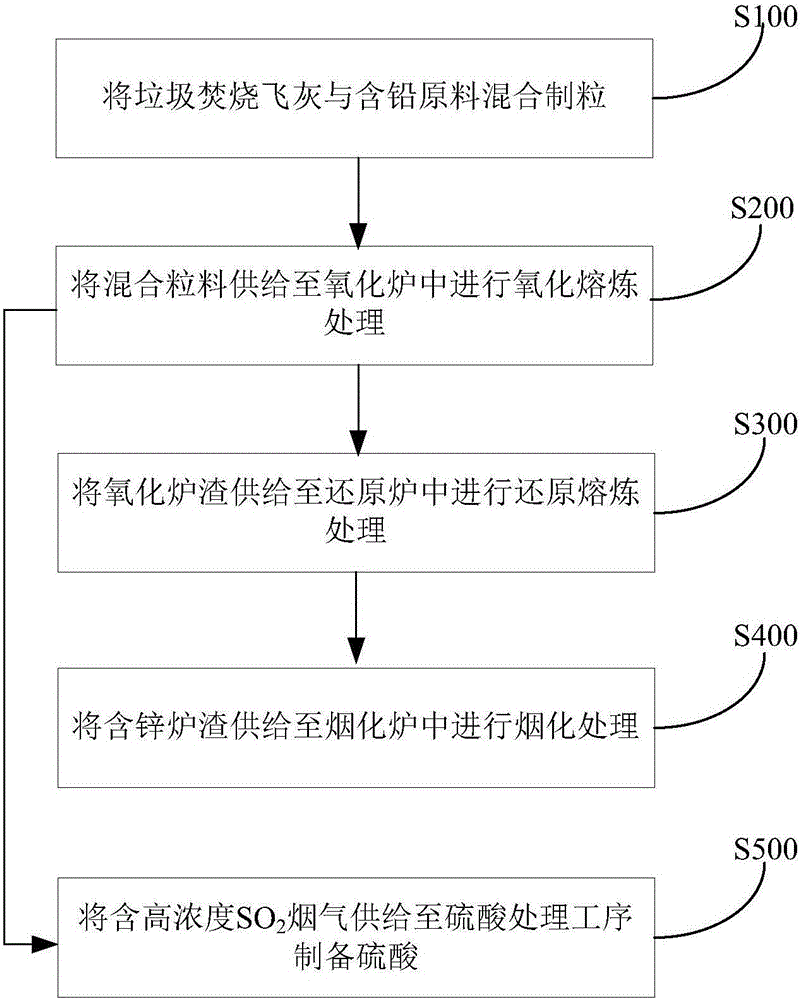

[0053] Waste incineration fly ash and lead-containing raw materials are mixed and granulated and then added to the oxidation furnace (the furnace type can be bottom-blown furnace, top-blown furnace or side-blown furnace). The quality of fly ash treatment accounts for 1%-5% of lead-containing raw materials Feed and smelting temperature is controlled at 1000-1100°C, dioxins in fly ash decompose at high temperature, and S is basically converted to SO 2 into the form containing high concentrations of SO 2 In the flue gas, it participates in acid production; most of Pb and Cu go into the crude lead melt, and a small part goes into the oxidation slag and lead-containing smoke, and the smoke and dust are closed-circuit circulation; Zn, Ca, Mg, Al, etc. enter the oxidation slag, and then oxidize the resulting The slag is supplied to the reduction furnace for reduction smelting treatment to obtain crude lead and zinc-containing slag, and then the obtained zinc-containing slag is suppli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com