A method for preparing micro-nanofibrous membranes with core-shell structure by electrospinning with janus parallel needles

A technology of micro-nano fiber and core-shell structure, which is applied in electrospinning, fiber processing, textiles and papermaking, etc., can solve the problems of inability to prepare fibers with core-shell structure, and achieve easy cleaning and maintenance, simple process flow, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

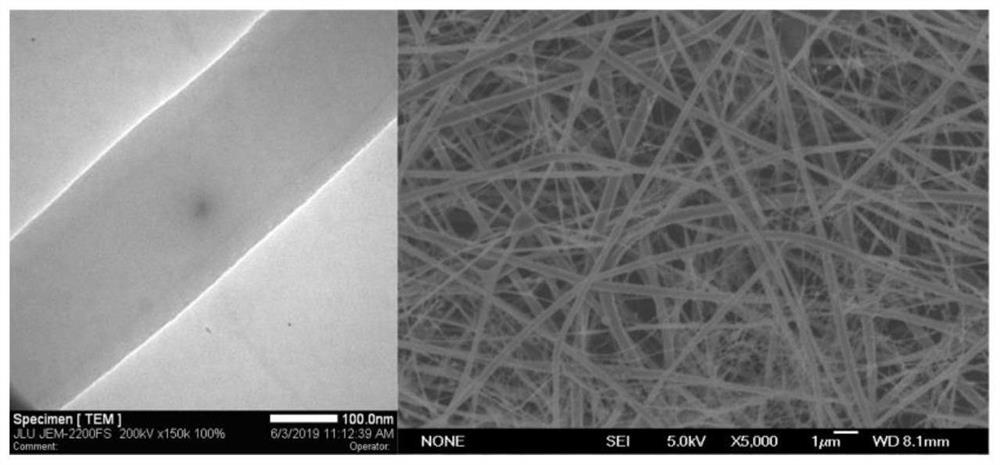

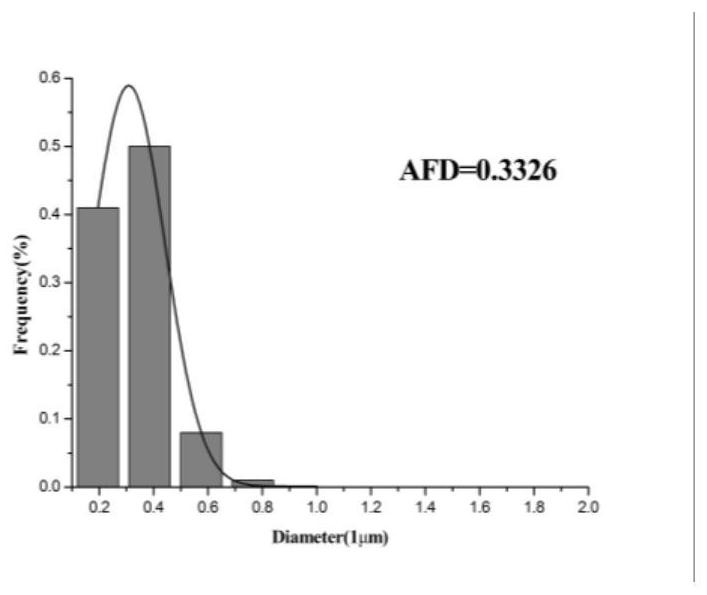

Embodiment 1

[0028] A1. Weigh 1-10g of lithium chloride and put it into beaker 1, then add 1-10g of dimethylacetamide. Stir on a magnetic stirrer for 2 hours to obtain a clear and uniform co-solvent; add cellulose powder to the well-mixed co-solvent, put the beaker 1 in an oil bath at 90°C and stir for 72 hours to get a well-mixed fiber prime solution;

[0029] A2. Measure 1-10 mL of acetone and add it to beaker 2, then add 1-10 mL of dimethylformamide. Stir on a magnetic stirrer for 2 hours to obtain a clear and uniform co-solvent; add 1 to 10 g of solid polyvinylidene fluoride to the uniformly mixed co-solvent, put the beaker 2 in an oil bath at 60°C and stir for 1 hour, A clear and homogeneous polyvinylidene fluoride solution is obtained;

[0030] B. Measure 2mL-3mL of the solution in beaker 1 in step A1, and inject the solution into syringe 1; measure 4mL-5mL of the solution in beaker 2 in step A2, and inject the solution into syringe 2; The two syringes are respectively fixed on di...

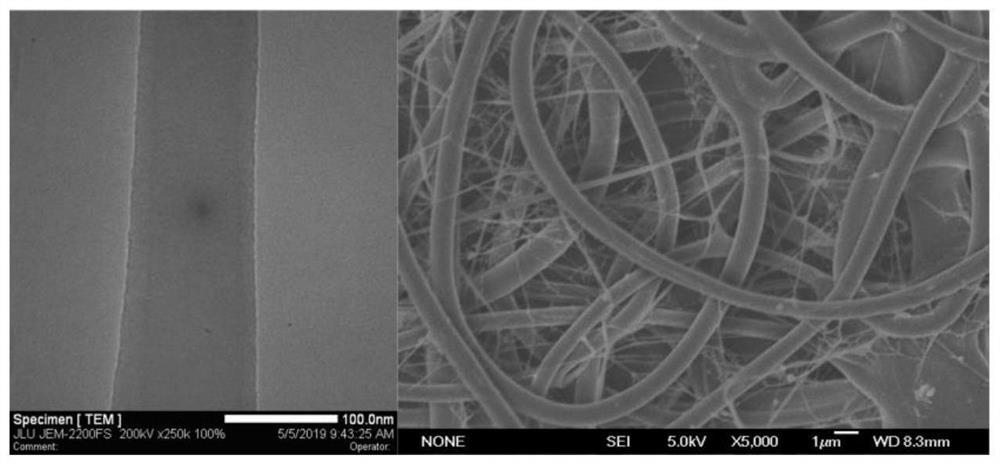

Embodiment 2

[0033] A1. Weigh 1-10g of lithium chloride and put it into beaker 1, then add 1-10g of dimethylacetamide. Stir on a magnetic stirrer for 2 hours to obtain a clear and uniform co-solvent; add cellulose powder to the well-mixed co-solvent, put the beaker 1 in an oil bath at 90°C and stir for 72 hours to get a well-mixed fiber prime solution;

[0034] A2. Measure 1-10 mL of acetone and add it to beaker 2, then add 1-10 mL of dimethylformamide. Stir on a magnetic stirrer for 2 hours to obtain a clear and uniform co-solvent; add 1 to 10 g of solid polyvinylidene fluoride to the uniformly mixed co-solvent, put the beaker 2 in an oil bath at 60°C and stir for 1 hour, A clear and homogeneous polyvinylidene fluoride solution is obtained;

[0035] B. Measure 2mL-3mL of the solution in beaker 1 in step A1, and inject the solution into syringe 1; measure 4mL-5mL of the solution in beaker 2 in step A2, and inject the solution into syringe 2; The two syringes are respectively fixed on di...

Embodiment 3

[0038] A1. Weigh 1-10g of lithium chloride and put it into beaker 1, then add 1-10g of dimethylacetamide. Stir on a magnetic stirrer for 2 hours to obtain a clear and uniform co-solvent; add cellulose powder to the well-mixed co-solvent, put the beaker 1 in an oil bath at 90°C and stir for 72 hours to get a well-mixed fiber prime solution;

[0039] A2. Measure 1-10 mL of acetone and add it to beaker 2, then add 1-10 mL of dimethylformamide. Stir on a magnetic stirrer for 2 hours to obtain a clear and uniform co-solvent; add 1 to 10 g of solid polyvinylidene fluoride to the uniformly mixed co-solvent, put the beaker 2 in an oil bath at 60°C and stir for 1 hour, A clear and homogeneous polyvinylidene fluoride solution is obtained;

[0040] B. Measure 2mL-3mL of the solution in beaker 1 in step A1, and inject the solution into syringe 1; measure 4mL-5mL of the solution in beaker 2 in step A2, and inject the solution into syringe 2; The two syringes are respectively fixed on di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com