Coal bed gas extraction method and system

A technology for coalbed methane and Christmas tree, which is applied in the field of coalbed methane drainage and production methods and systems, can solve the problems of poor gas regulation accuracy, difficulty in parameter regulation, and many parameters, and achieves the effects of improving gas regulation precision and improving coalbed methane production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

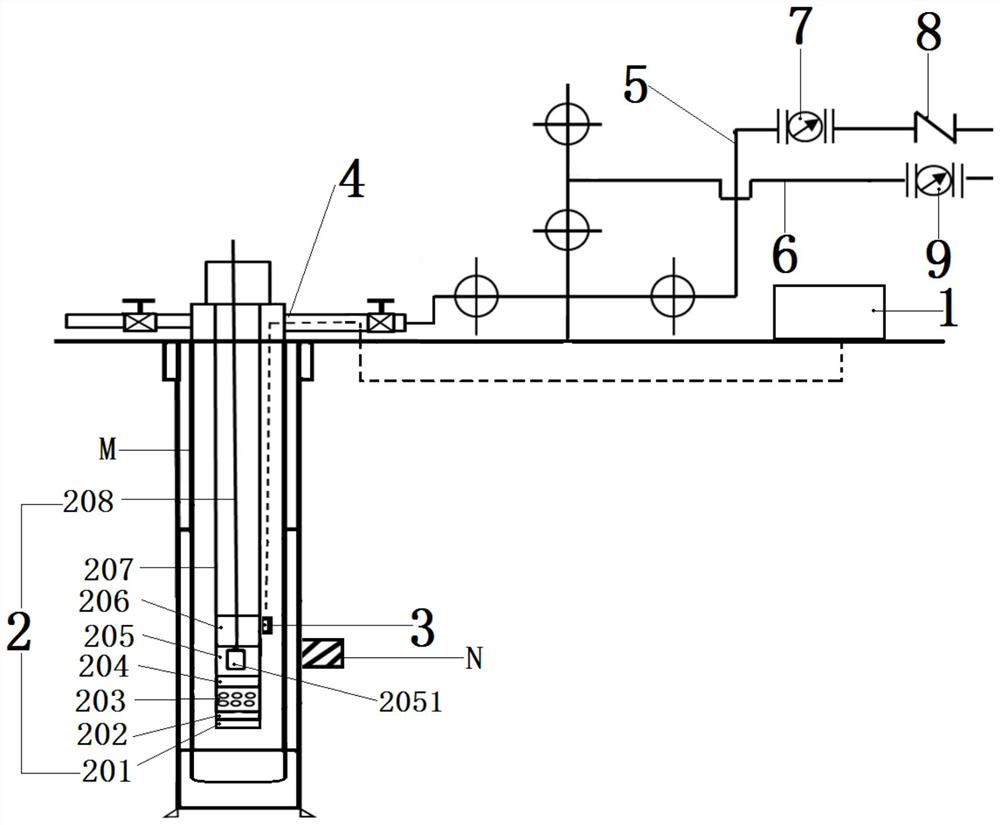

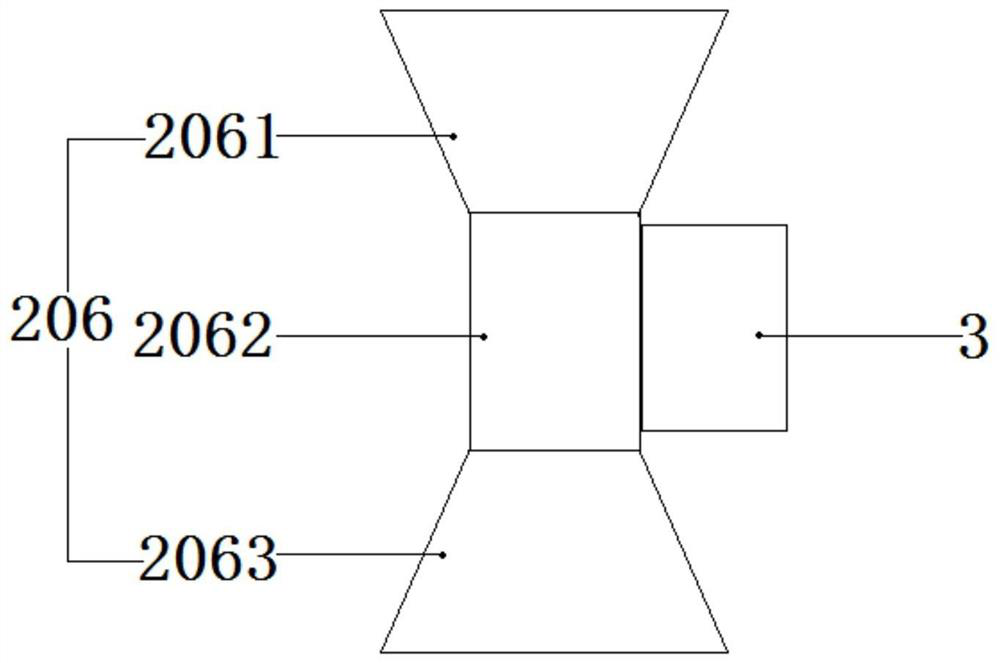

[0133] This embodiment provides a coalbed methane drainage system, which includes: a control box 1, a tubular pump oil pipe string 2, a downhole pressure gauge 3, a wellhead Christmas tree 4, a gas production pipeline 5, a water production pipeline 6, a A flow meter 7, a check valve 8, a second flow meter 9, a pumping unit, and terminal equipment. Among them, the tubing pump tubing string 2 includes: a screw plug 201 (D89mm×0.10m), a tubing nipple 202 (D73mm×1.50m), a stainless steel screen 203 (D89mm×2.03 m, sieve hole is 80 mesh), tailpipe 204 (D73mm×9.81m), tube pump 205 (D44mm×4.83m), support cylinder 206 (length 1.25m), 93 connected flat oil pipes 207 (D73mm× 909.27m), double male nipple (D73mm×0.15m), tubing hanger (0.13m in length), oil filling distance (0.3m in length). The downhole pressure gauge 3 is arranged on the outer wall of the reduced-diameter section 2062 of the supporting cylinder 206, and is electrically connected to the control box 1 through a cable. The ...

Embodiment 2

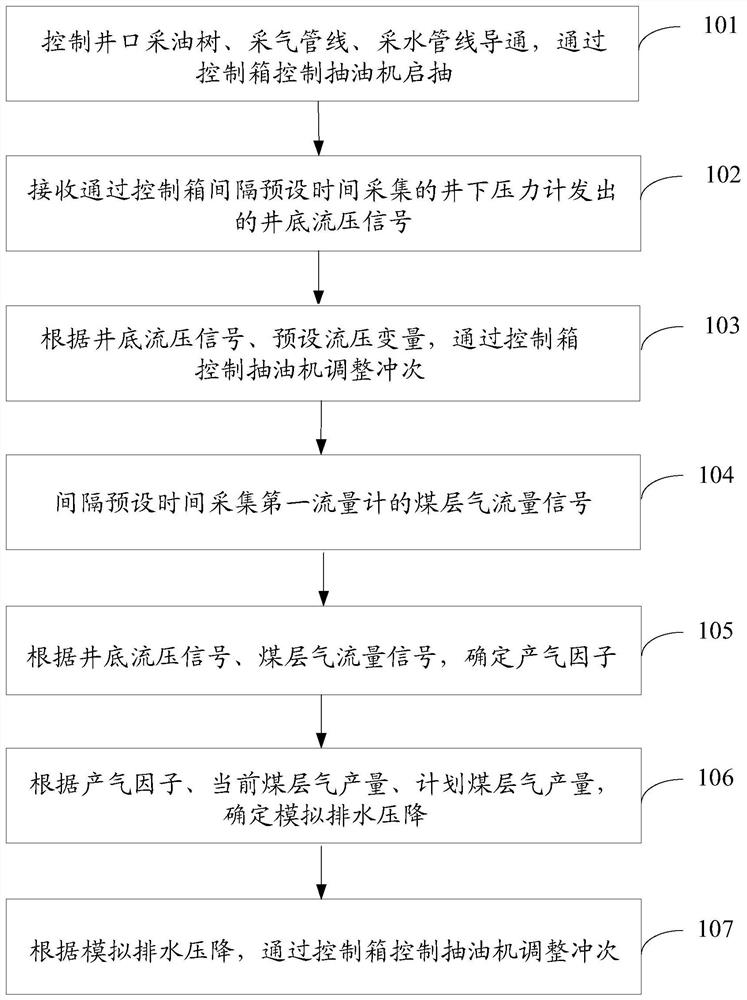

[0139] This embodiment provides a coalbed methane extraction method, which is applied to the coalbed methane extraction device provided in Embodiment 1. This method is applied to the coalbed methane well Q18-29 in the southern Qinshui Basin. The depth of the coal seam section is 904.3-910.3m, the inner diameter of the production casing M is 139.7mm, the depth of the completion well is 1028m, and the depth of the artificial well bottom is 936m. The method specifically includes:

[0140] Step 201, open the first system valve, the second system valve on the wellhead Christmas tree 4, and the check valve 8 on the gas production pipeline 5, so that the wellhead Christmas tree 4, the gas production pipeline 5, and the water production pipeline 6 are connected, Control the pumping unit to start pumping at a speed of 1 time / min through the control box 1.

[0141] Step 202, the terminal equipment receives the downhole flow pressure signal sent by the downhole pressure gauge 3 collecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com