Carbon deposition removal and removal method for vehicle vibration

A vehicle and carbon deposition technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as idling engines, insufficient attention, vibration, etc., and achieve the effects of easy control, simple operation, and time-saving removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

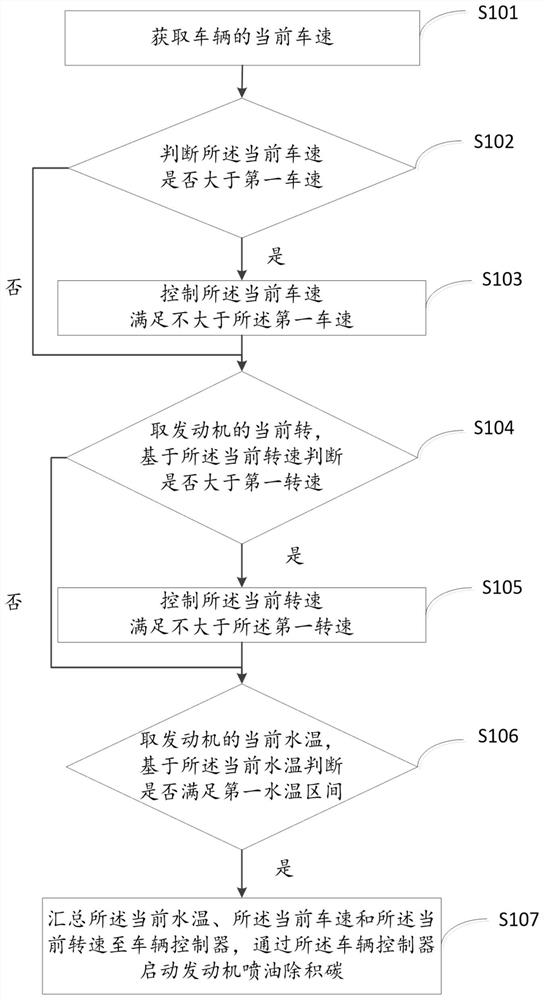

[0050] This embodiment one provides a kind of carbon deposition removal for vehicle shaking, such as figure 1 shown, including:

[0051] S101. Obtain the current speed of the vehicle;

[0052] S102. Judging whether the current vehicle speed is greater than the first vehicle speed;

[0053] S103. When the current vehicle speed is greater than the first vehicle speed, control the vehicle speed to be not greater than the first vehicle speed;

[0054] S104. When the current speed is not greater than the first speed, obtain the current speed of the engine, and judge whether it is greater than the first speed based on the current speed;

[0055] S105. When the current rotation speed is greater than the first rotation speed, control the current rotation speed to be not greater than the first rotation speed;

[0056] S106. When the rotational speed is not greater than the first rotational speed, obtain the current water temperature of the engine, and judge whether the first water t...

Embodiment 2

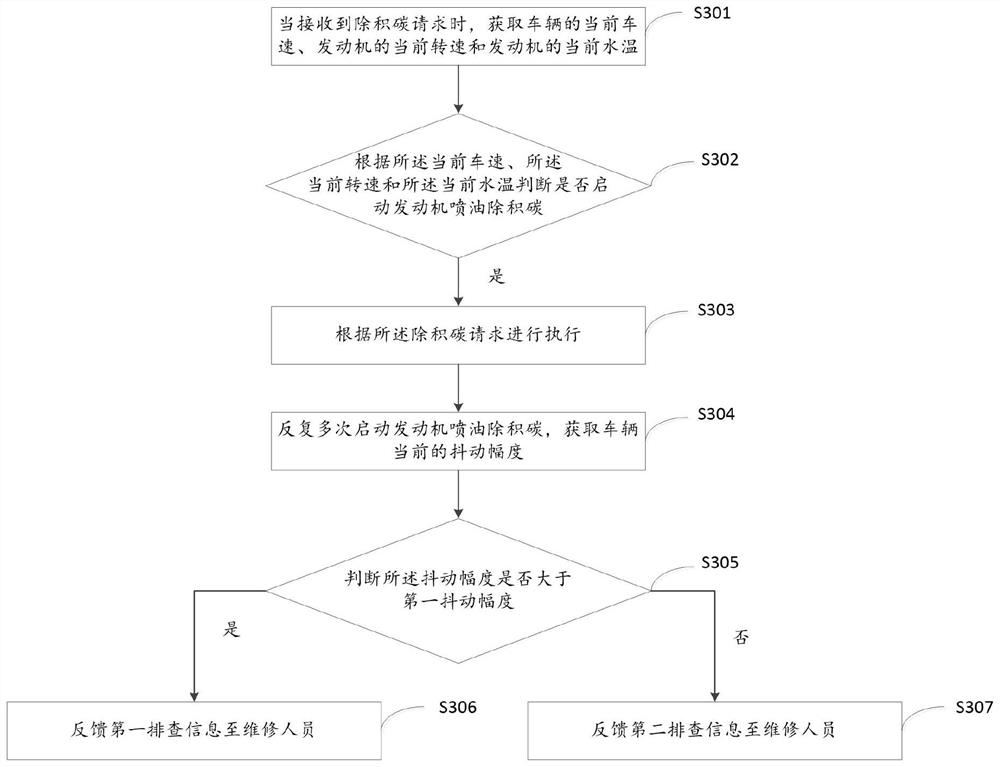

[0069] The second embodiment provides a method for troubleshooting vehicle vibration, such as image 3 shown, including:

[0070] S301. Obtain the current vehicle speed of the vehicle, the current rotational speed of the engine, and the current water temperature of the engine when the carbon deposit removal request is received;

[0071] S302. According to the current vehicle speed, the current rotational speed and the current water temperature, judge whether to start engine fuel injection to remove carbon deposits;

[0072] S303. If the engine fuel injection is started to remove carbon deposits, execute according to the carbon deposit removal request;

[0073] S304. Repeatedly start the engine to inject fuel to remove carbon deposits, and obtain the current vibration amplitude of the vehicle;

[0074] S305. Determine whether the jitter amplitude is greater than the first jitter amplitude;

[0075] S306. If the vibration amplitude is not greater than the first vibration ampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com