Evaporator of air source heat pump and design method and air source heat pump comprising same

A technology of air source heat pump and design method, which is applied in the direction of evaporator/condenser, lighting and heating equipment, refrigeration and liquefaction, etc. It can solve the problem of fast frosting on the surface of fins, fast blocking of channels by frost layer, and defrosting cycle Short and other problems, to achieve the effect of accelerated frosting speed, long growth and blockage time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

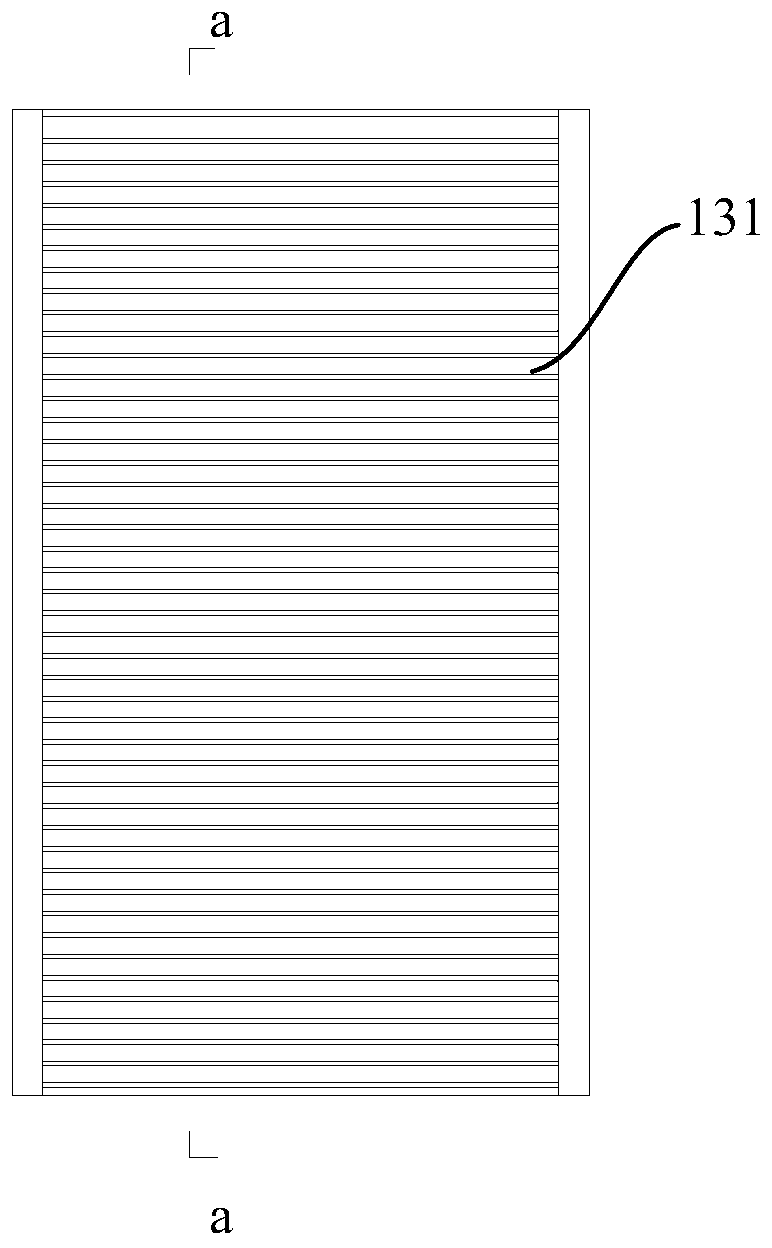

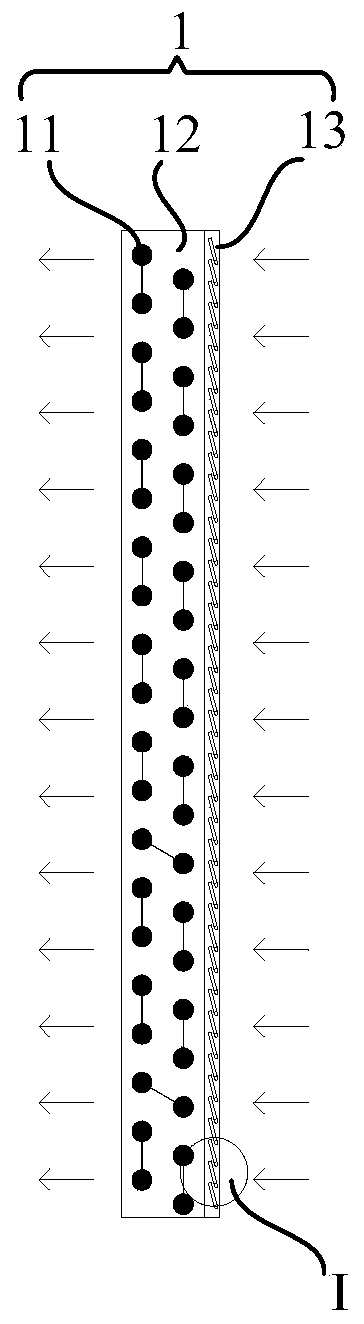

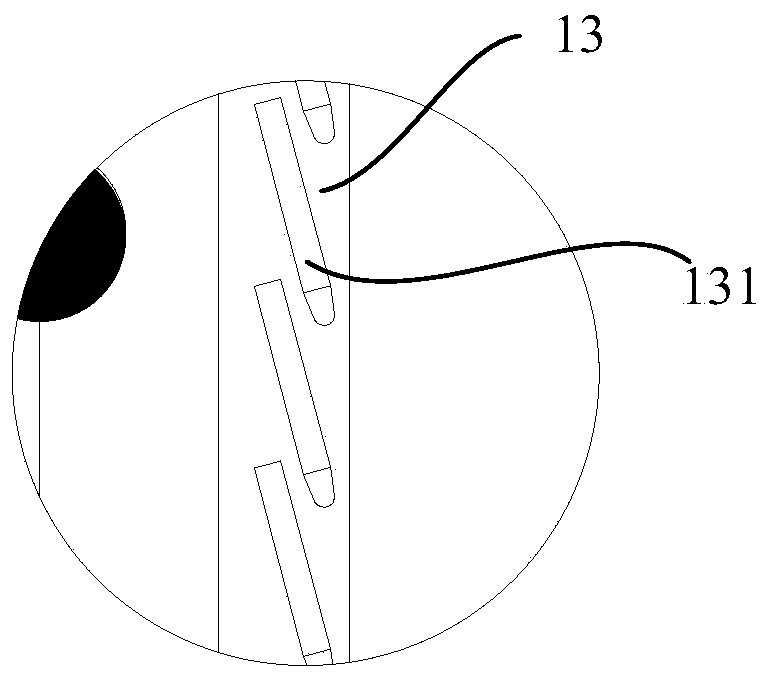

[0075] The invention provides a design method of an air source heat pump evaporator, the air source heat pump evaporator includes a refrigerant pipeline and a plurality of fins mounted in series on the refrigerant pipeline, and a design capable of The guiding structure that guides the water vapor in the air to liquefy instead of desublimate, based on the design method in the present invention, this embodiment provides a Figure 1-4 The shown air source heat pump evaporator 1, the air source heat pump evaporator 1 includes a refrigerant pipeline 11 and a plurality of fins 12 mounted on the refrigerant pipeline 11 in series, and is arranged on the windward side of the air source heat pump evaporator 1 There is a guide structure (grid 13) that can guide the water vapor in the air to liquefy into water rather than condense into frost.

[0076] An air source heat pump evaporator and design method of the present invention and an air source heat pump containing the evaporator are pro...

Embodiment 2

[0083] Such as Figure 5 As shown, this embodiment provides an air source heat pump evaporator, which is different from Embodiment 1 in that the blade head 1311 on the grid blade 131 in this embodiment includes a first slope 13111, a second slope 13114 and a cylindrical surface 13112, the two sides of the cylindrical surface 13112 are respectively tangent to one side of the first slope 13111 and the second slope 13114, and the other side of the first slope 13111 and the second slope 13114 are along the air flow direction It is opened and connected to the two sides of the blade body 1312 in a smooth transition, and a hollow structure 13113 is provided in the blade head 1311. This structure can make the blade head 1311 more smooth and not easy to attach, and in order to achieve better results In this embodiment, the first slope 13111 and the second slope 13114 are arranged symmetrically on both sides of the cylindrical surface 13112, and the angle φ between the first slope 13111...

Embodiment 3

[0086] Such as Figure 6-8 As shown, this embodiment provides an air source heat pump evaporator 1, which differs from Embodiment 1 in that the gap direction of the blades 131a of the grid 13a is the same as the gap direction of the fins 12 of the air source heat pump evaporator 1 The number of blades 131 a of the grid 13 a corresponds to the number of the fins 12 , and the tails of the blades 131 a are in smooth contact with the windward side of the fins 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com