Method for calibrating sub-pixel size of surface particulate pollutant of large-diameter reflector

A large-diameter mirror and surface particle technology, applied in the field of engineering optics, can solve the problem of low precision, achieve the effect of improving calibration precision and meeting cleanliness testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

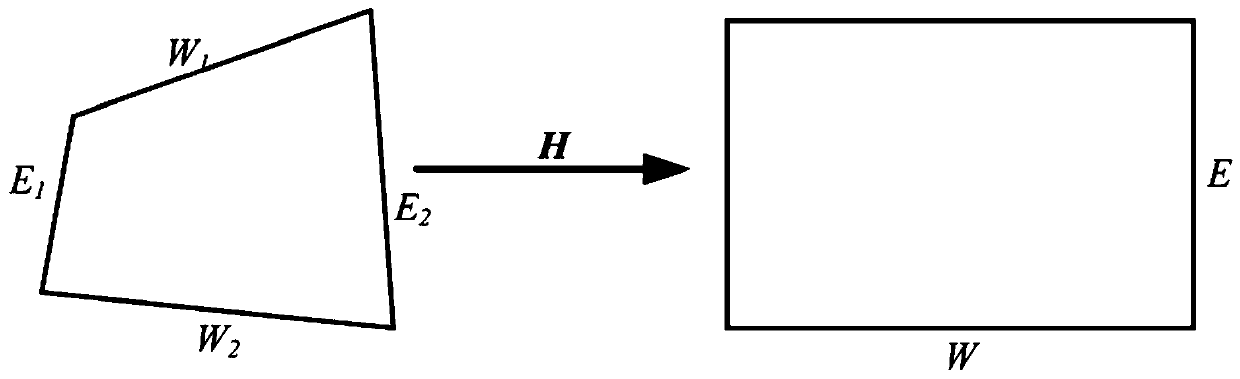

[0038] Specific implementation mode 1: In this implementation mode, the specific process of a sub-pixel size calibration method for particle pollutants on the surface of a large-aperture mirror is as follows:

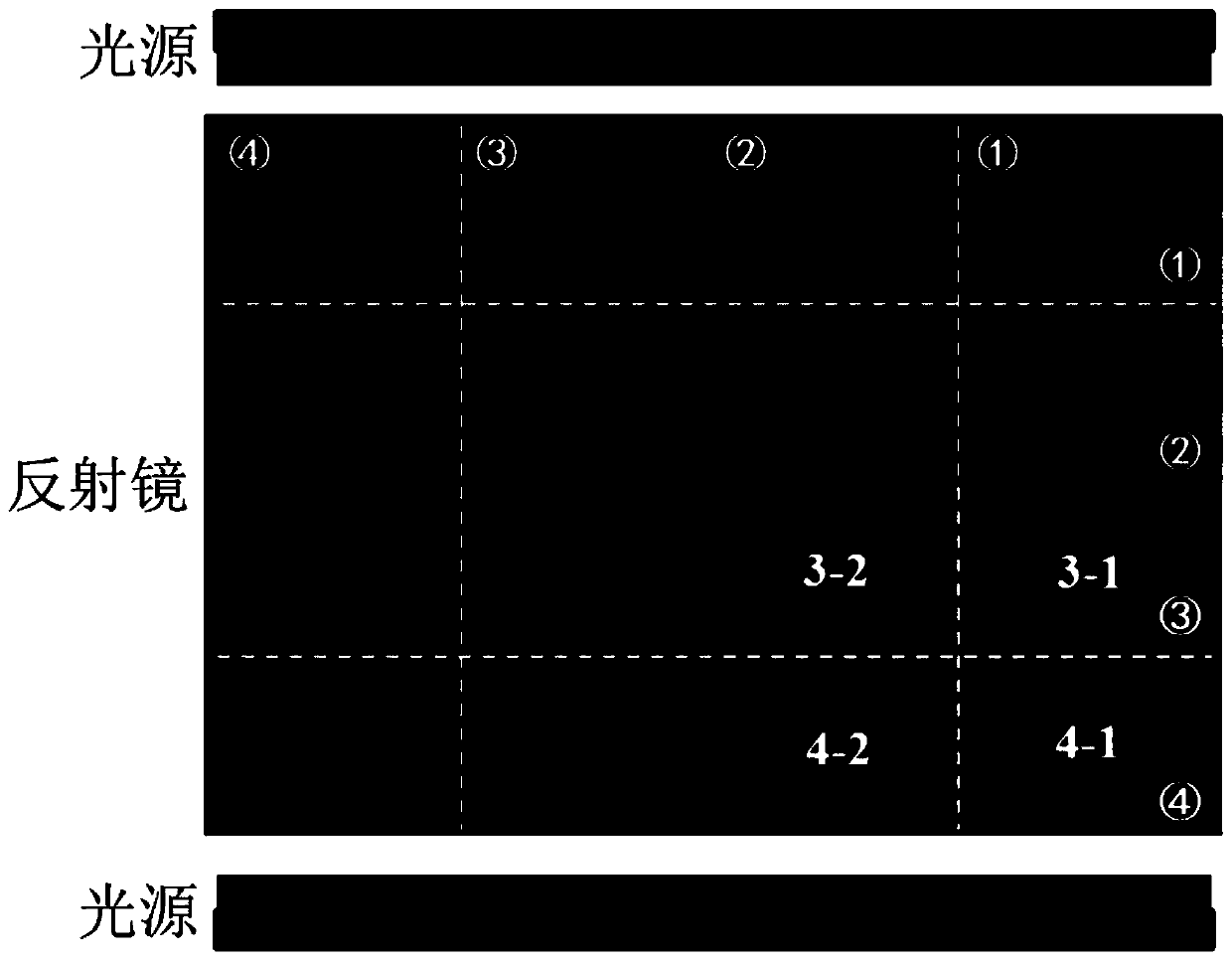

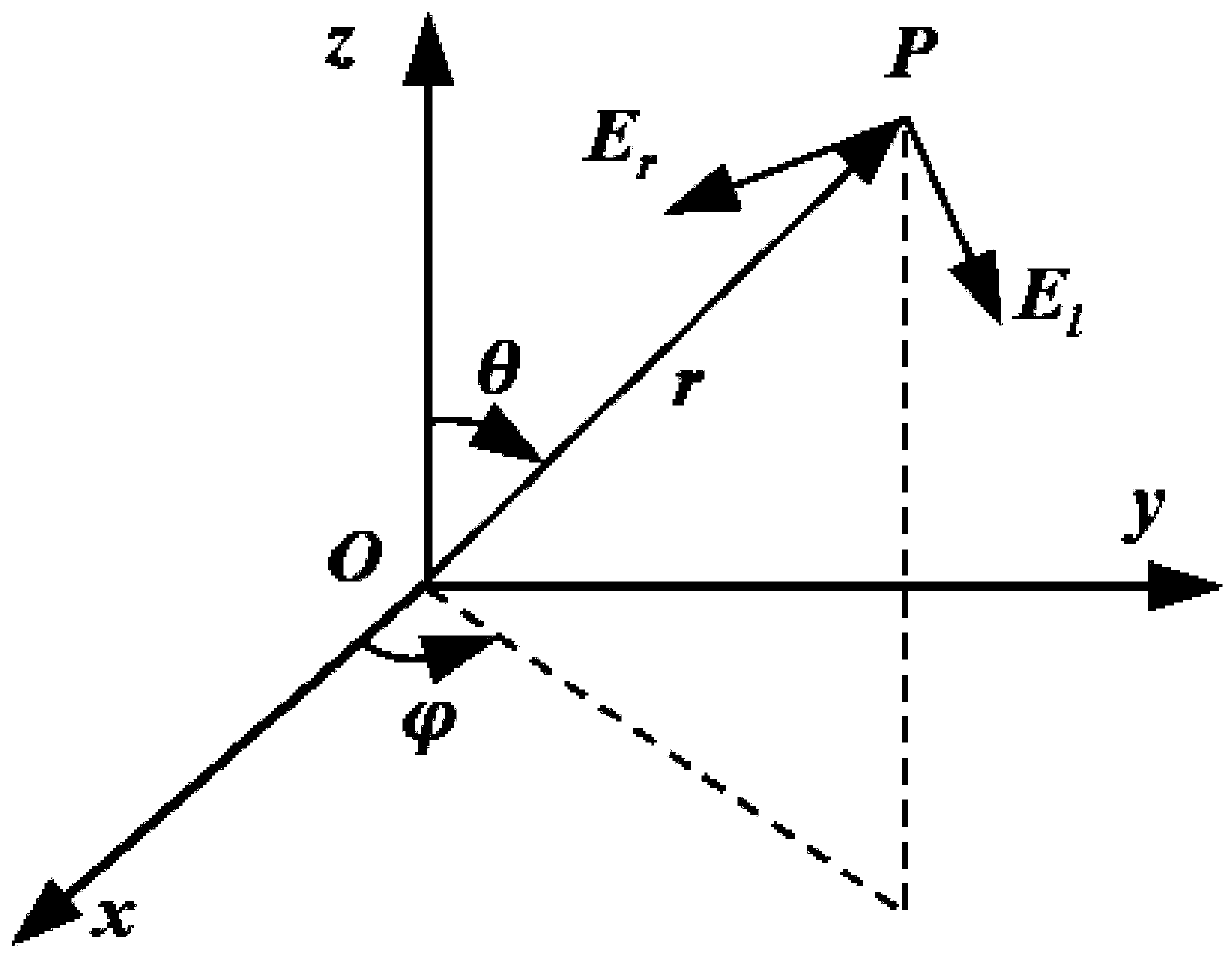

[0039] For the detection of particle pollutants on the surface of large-aperture mirrors, the detection method of dark field imaging is adopted. The high-brightness linear array light source is installed on both sides of the front surface of the mirror, and irradiates on both sides of the mirror at a low angle. The mirror surface, the imaging system is installed on the front surface of the mirror and facing the mirror surface. If there are particle pollutants on the surface of the mirror, the reflected light of the particle pollutants will be incident on the photosensitive element of the imaging system, while the light in other areas cannot enter the imaging system, thus forming a bright object image under a dark background, the control system Image processing can be pe...

specific Embodiment approach 2

[0047] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in the first step, the entire light-transmitting area is divided into 4×4 sub-areas, and a calibration plate with the same size as the sub-area is prepared, and the calibration plate Silica particles of different sizes are preset on the top; the specific process is:

[0048] Step 11, using a pure black opaque plexiglass plate to make a calibration plate with the same size as the sub-area to reduce the impact of stray light on the size calibration results of particle pollutants;

[0049] Step 12. Make the calibration plate generate static electricity by friction, etc., and use different sizes of SiO 2 The particles are evenly sprinkled on the surface of the calibration plate, and the static electricity of the calibration plate will adsorb SiO 2 Granular, guaranteed SiO 2 The particle position does not change.

[0050] Other steps and parameters are the same as those in Embo...

specific Embodiment approach 3

[0051] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in the step 2, the calibration plates are sequentially placed on different sub-regions that are evenly divided on the surface of the mirror, and the calibration plates in different areas are collected respectively Picture; the specific process is:

[0052] Step 21. Install the large-diameter reflector on the offline dark field detection device (the offline dark field detection device includes an outer frame, a reflector, a light source unit, a guide rail and an image monitoring unit. This offline dark field monitoring device can obtain different monitoring distances Monitoring images of particulate contamination on the surface of the lower reflector, such as Figure 8 ), and use the clamping device to pre-tighten;

[0053] The aperture of the commonly used optical element is within 100mm, but the aperture of the optical element used in this paper is more than 600mm, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com