Motor speed measurement sensor

A sensor and motor measurement technology, which is applied in the direction of instruments, measuring devices, linear/angular velocity measurement, etc., can solve the problems of large volume, complex calculation circuit, high cost, etc., and achieve the effect of improving accuracy, minimum resolution and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

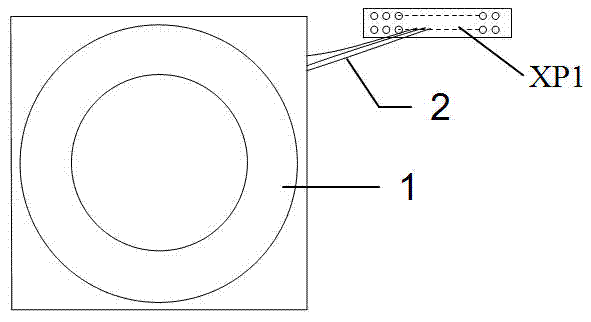

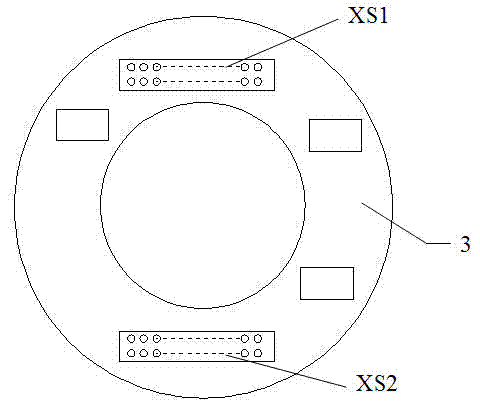

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

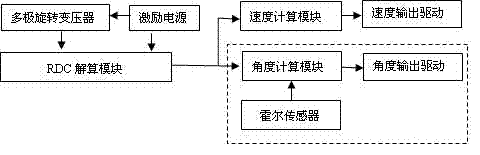

[0018] The output signal of the resolver is a two-phase quadrature analog signal, and their amplitude varies with the rotation angle as sine and cosine. The RDC resolver circuit measures the angle of rotation by calculating the amplitude of the output signal of the resolver. Every time the rotating shaft of the unipolar resolver rotates one revolution, the output sine and cosine signals change one revolution, and the position calculated by the RDC resolver also changes. One cycle, such as a 12-bit RDC resolver, when the rotary shaft of a unipolar resolver rotates one cycle, the output data of the 12-bit RDC resolver changes from 0 to 4096; The cosine signal changes for several cycles according to the number of pole pairs. For example, for a 4-pole resolver, when the rotating shaft rotates once, the amplitude of the output sine and cos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com