Manufacturing method of zeroth interlayer film

A manufacturing method and technology of nitride film, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as abnormal electrical properties of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

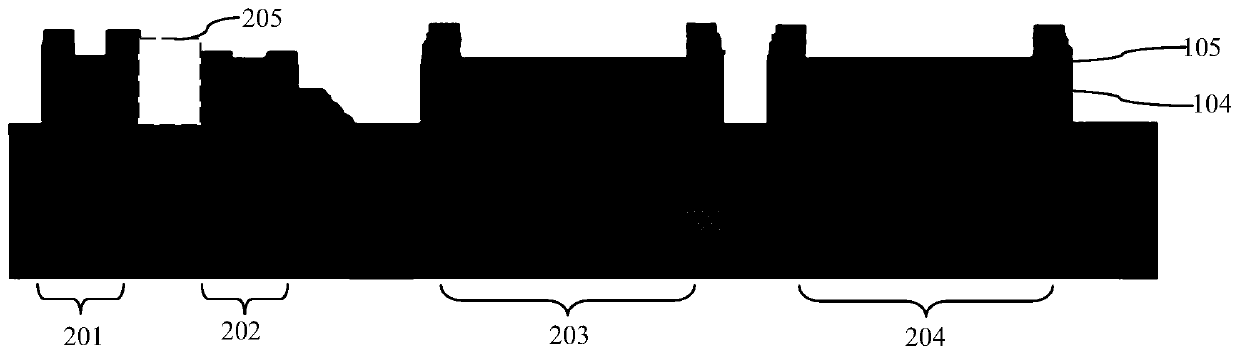

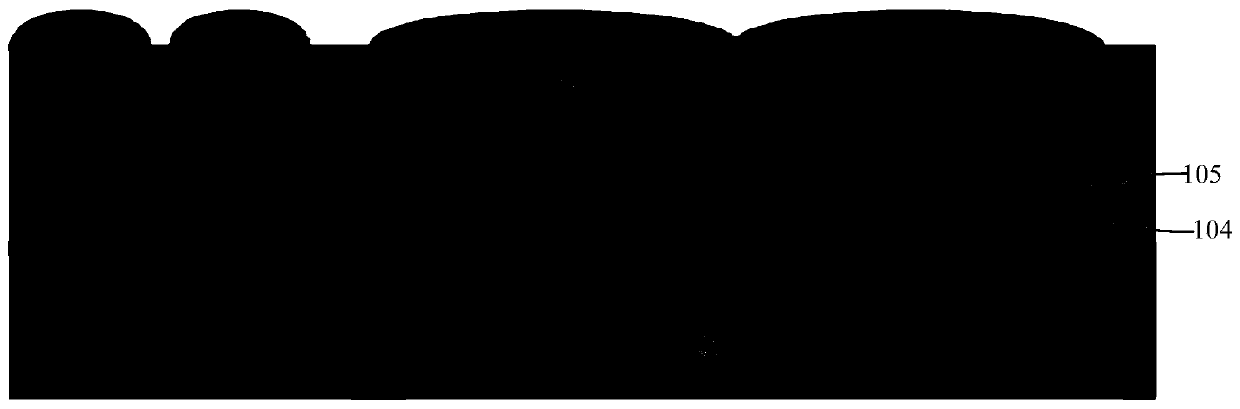

[0060] like figure 2 As shown, it is a flow chart of the manufacturing method of the zeroth layer interlayer film 7 according to the embodiment of the present invention; 3A to 3E As shown, it is a device structure diagram in each step of the manufacturing method of the zeroth layer interlayer film 7 according to the embodiment of the present invention. The manufacturing method of the zeroth layer interlayer film 7 according to the embodiment of the present invention includes the following steps:

[0061] Step one, as Figure 3A As shown, a semiconductor substrate 1 is provided, and on the surface of the semiconductor substrate 1, a plurality of first gate structures formed by superimposing a gate dielectric layer and a polysilicon gate 3 are formed; The area is the spacer 305 .

[0062] A spacer 4 is formed on the side of the first gate structure, and the top surface of the spacer 4 is higher than the top surface of the polysilicon gate 3 .

[0063] A contact hole etch st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com