Coaxial double-blade cutter inclined-insertion machining tool and machining method

A double-edged tool and oblique insertion technology, which is applied to metal processing equipment, cutting tools for planer/slotting machines, manufacturing tools, etc., can solve the problems of high requirements for machine tools, low processing efficiency, and large equipment investment, so as to improve processing flexibility , simple structure, and the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

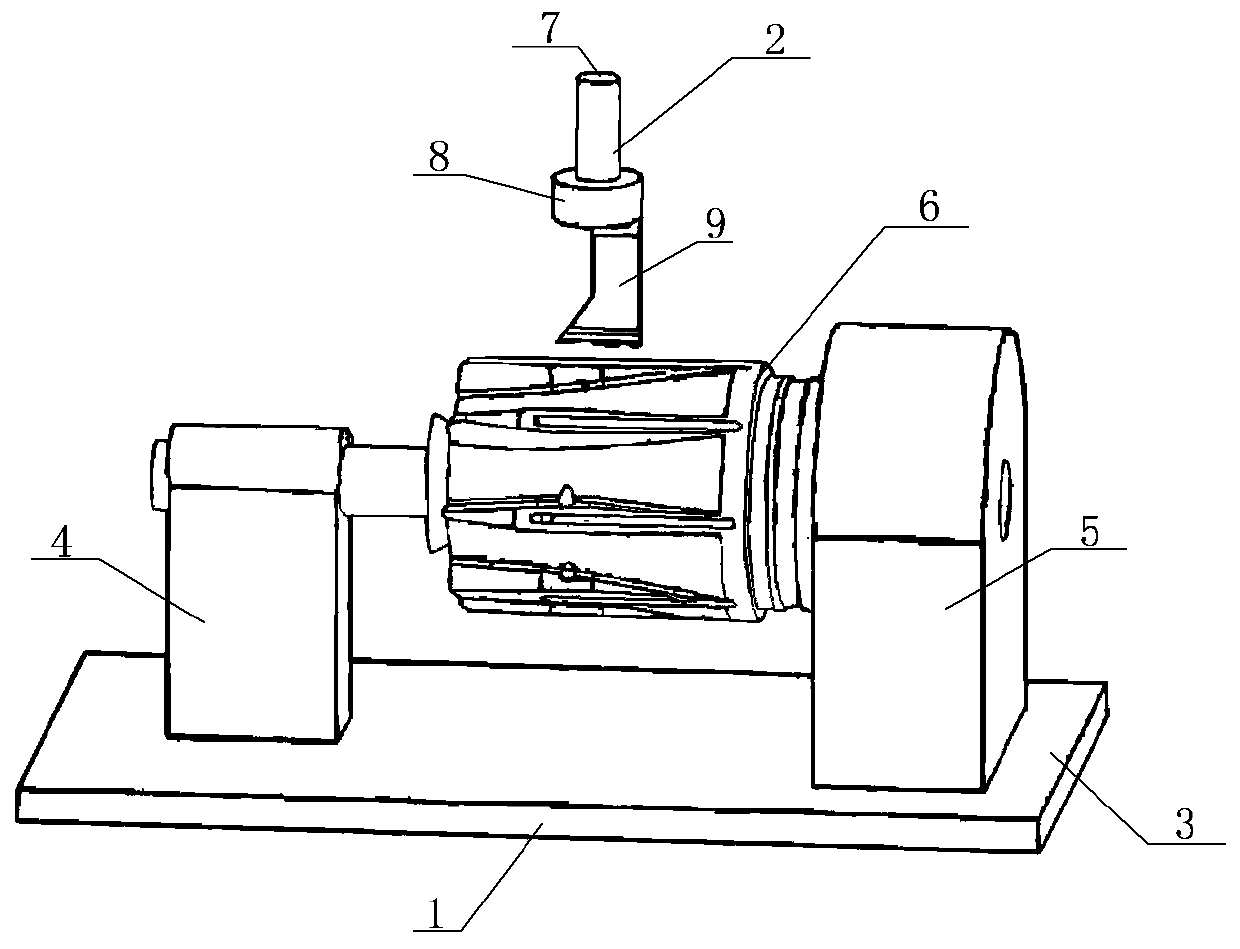

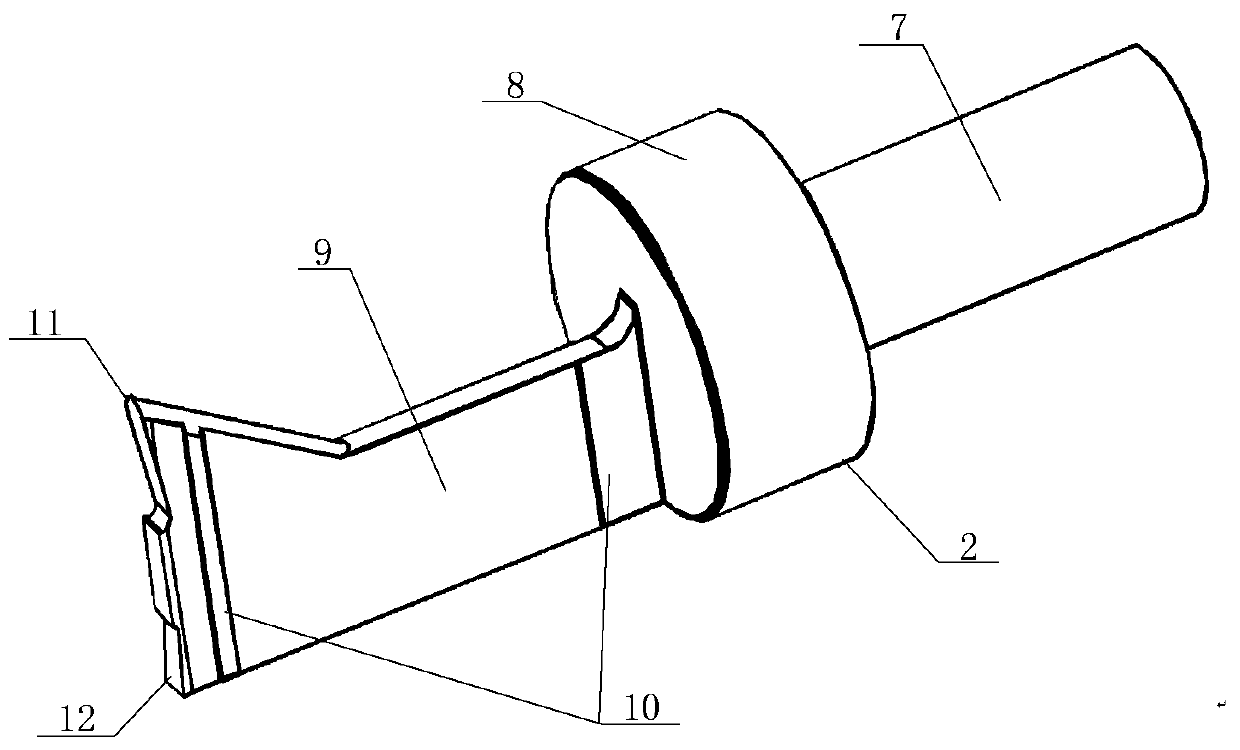

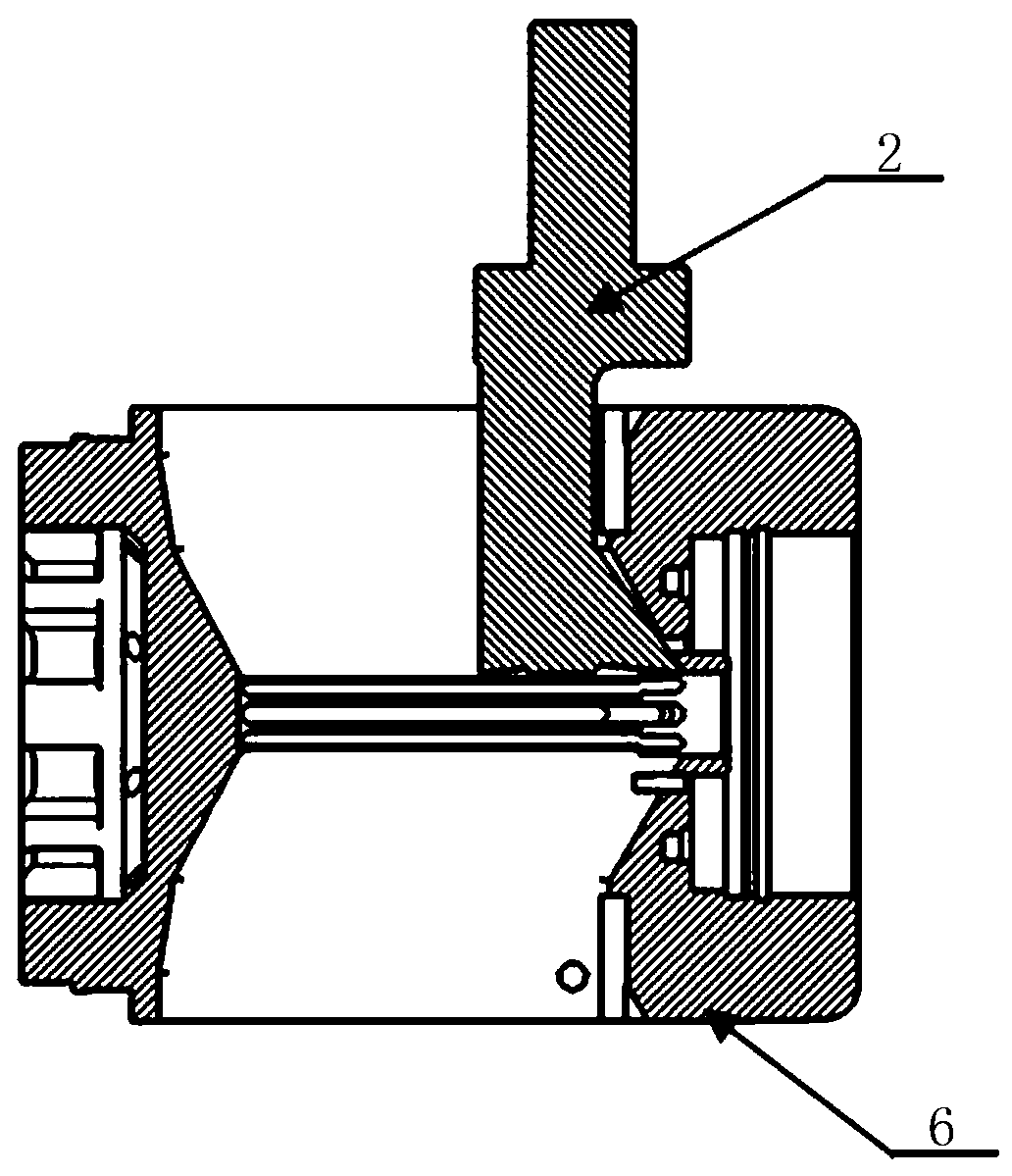

[0018] The specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings. Such as Figure 1-8 Shown: a coaxial double-edged tool oblique insertion processing tool, the coaxial double-edged tool oblique insertion processing tool is composed of a tooling body 1 and a double-edged tool 2, and the tooling body 1 is composed of a base 3 and a tailstock 4 Composed of indexing head 5, the left end of the top surface of the base 3 is provided with a tailstock 4, the right end of the top surface of the base 3 is provided with an indexing head 5, and a workpiece is clamped between the tailstock 4 and the indexing head 5 6. The top of the workpiece 6 is provided with a double-edged cutter 2 for slot milling. The double-edged cutter 2 is composed of a clamping part 7, a connecting part 8 and a cutting body 9. The bottom end of the clamping part 7 is provided with a There is a connecting portion 8, the bottom center of the connecting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap