Glasses foot machining shaping mold and machining shaping method

A technology for processing molding and mirror feet, which is applied to home appliances, other household appliances, frames, etc., can solve the problems of increased processing costs of mirror feet, increased materials used for metal poles, and increased difficulty of grinding incisions, etc., to achieve better product quality , The effect of reducing the material used for metal struts and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

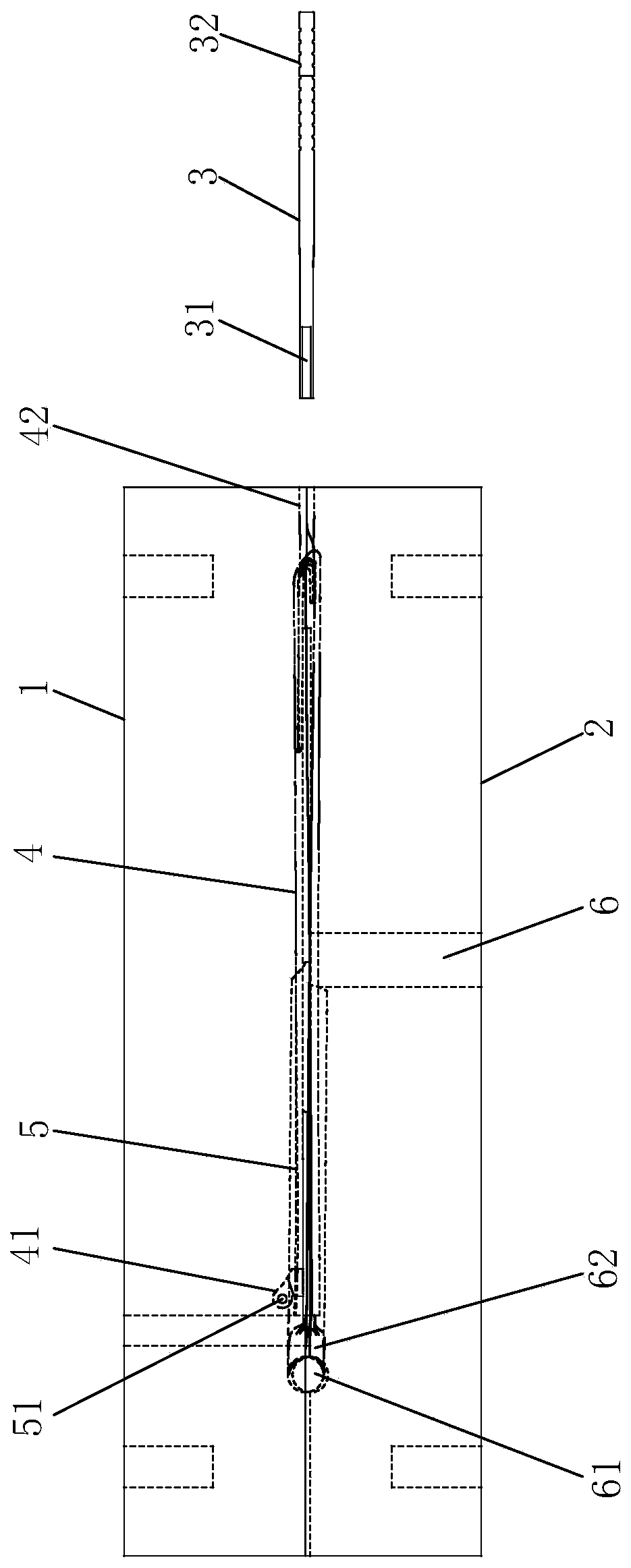

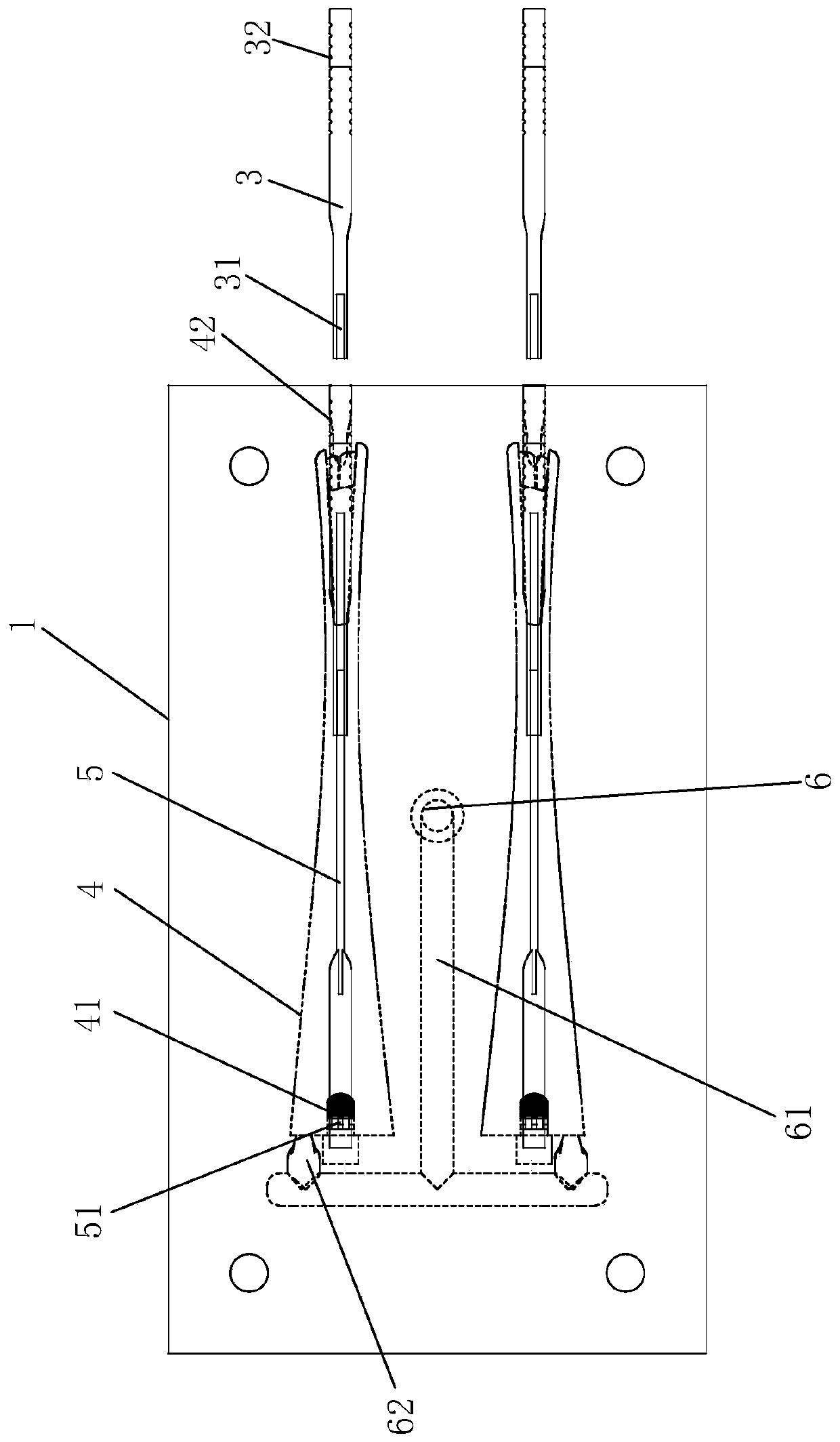

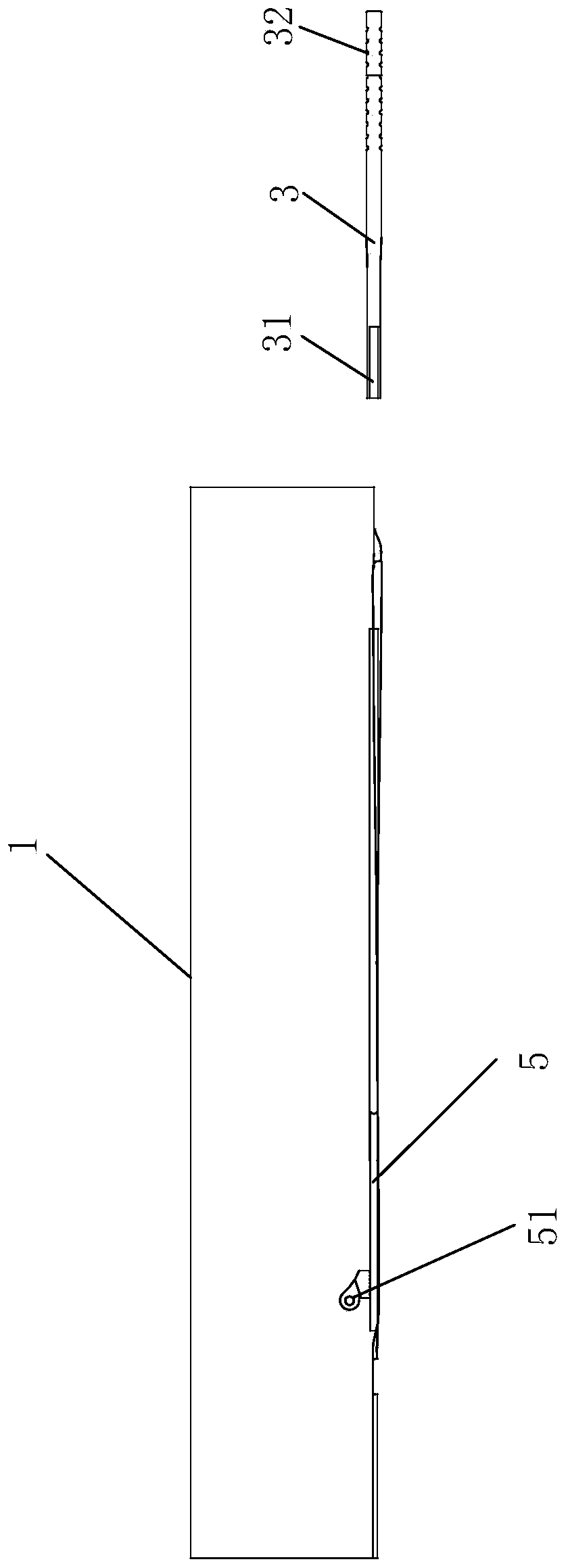

[0044] Such as Figure 1 to Figure 6 As shown, the present invention discloses a processing mold for spectacle temples, which has an upper mold 1, a lower mold 2 and a rubber tube 3, the upper mold 1 and the lower mold 2 are molded together, and between the upper mold 1 and the lower mold 2 A temple cavity 4 is formed, and the metal pole 5 is arranged in the temple cavity 4. The front end of the temple cavity 4 has a support groove 41, and the support groove 41 is inserted into the temple hinge seat 51 of the metal pole 5. The rear end of the temple cavity 4 forms a socket 42 that runs through the mold. The socket 42 is used for the insertion of the rubber tube 3. The temple cavity 4 is connected to the outside of the mold through the socket 42. The tail end of the support rod 5, so that the rubber tube 3 can extend into the temple cavity 4 when the mirror feet are processed, and is set on the tail end of the metal support rod 5, and is used to support the tail end of the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com