Connection node for adjacent prefabricated members and construction method of connection node

A technology for prefabricated components and connecting nodes, applied in building construction, building material processing, construction, etc., can solve the problems of limiting the minimum thickness of floor slabs, increasing costs, increasing the cost of steel bars, etc., to improve construction efficiency and construction quality, reduce Labor cost, the effect of ensuring safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

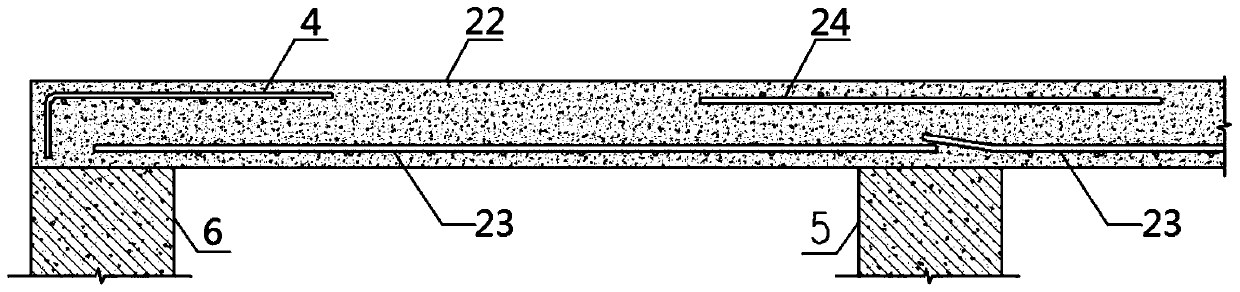

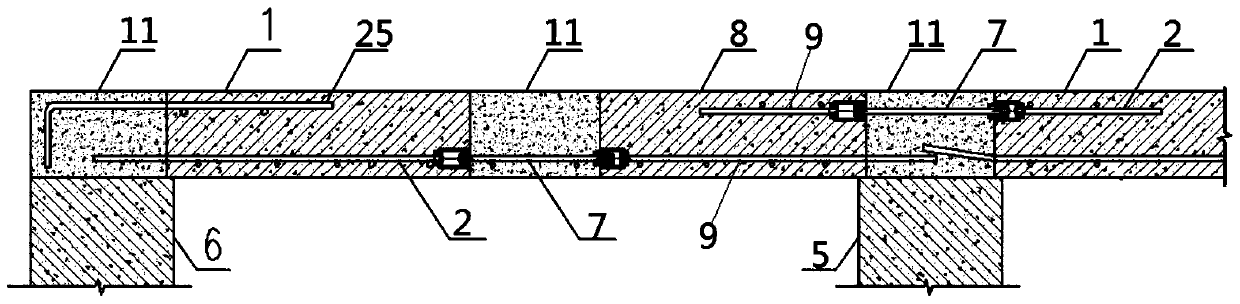

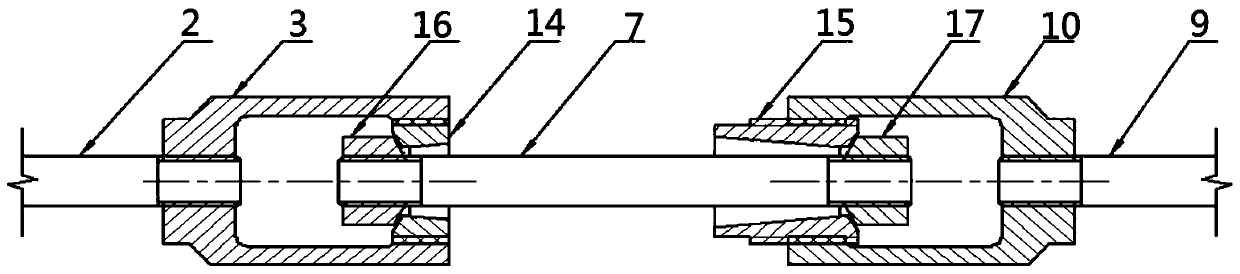

[0059] Such as Figure 2 to Figure 11 , the connection node of adjacent prefabricated floor slabs, used for the connection between the adjacent first prefabricated component 1 and the second prefabricated component 8, the opposite ends of the first prefabricated component 1 and the second prefabricated component 8 are placed on the first bearing On the force member 5, or suspended in the air; the first prefabricated component 1 is embedded with a number of first steel bars 2 extending toward the direction of the second prefabricated component 8, and the second prefabricated component 8 is embedded with a plurality of A second steel bar 9 extending in the direction of the prefabricated component 1, the first steel bar 2 and the second steel bar 9 are arranged in pairs; the end of the first steel bar 2 close to the second prefabricated component 8 is connected with a first cylinder 3. The first cylinder 3 opens toward the second prefabricated component 8, and the second steel ba...

Embodiment 2

[0074] see Figure 12 to Figure 21 , the connection node of adjacent prefabricated floor slabs, used for the connection between the adjacent first prefabricated component 1 and the second prefabricated component 8, the opposite ends of the first prefabricated component 1 and the second prefabricated component 8 are placed on the first bearing On the force member 5, or suspended in the air; the first prefabricated member 1 is embedded with a number of first steel bars 2 extending toward the direction of the second prefabricated member 8, and the second prefabricated member 8 is embedded with several A second steel bar 9 extending in the direction of the prefabricated component 1, the first steel bar 2 and the second steel bar 9 are arranged in pairs; the end of the first steel bar 2 close to the second prefabricated component 8 is connected with a first cylinder 3. The first cylinder 3 opens toward the second prefabricated component 8, and the second steel bar 9 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com