Hydraulic auxiliary splitting device and method for rock breakage

A hydraulic and equipment technology, applied in the hydraulic splitting field of rock crushing, which can solve problems such as dust pollution, noise pollution, and slow expansion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

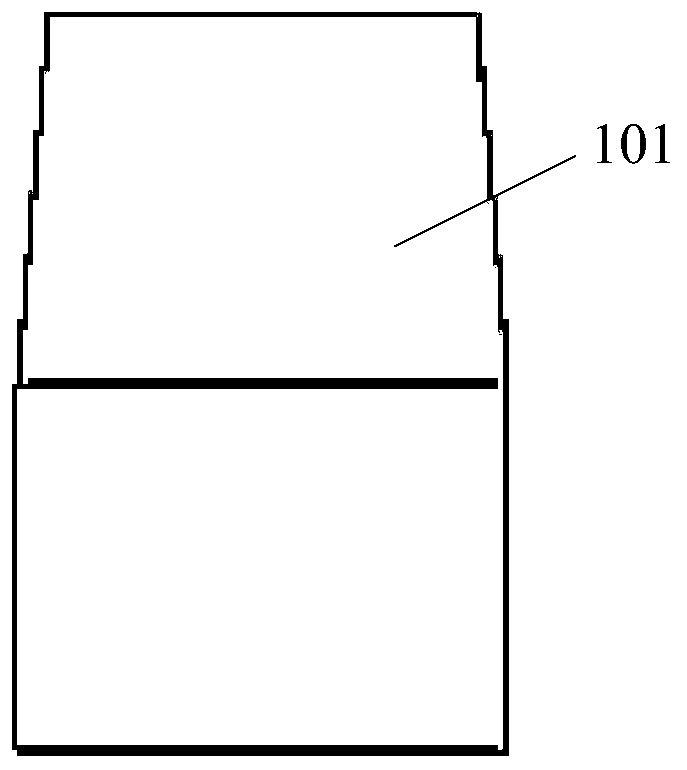

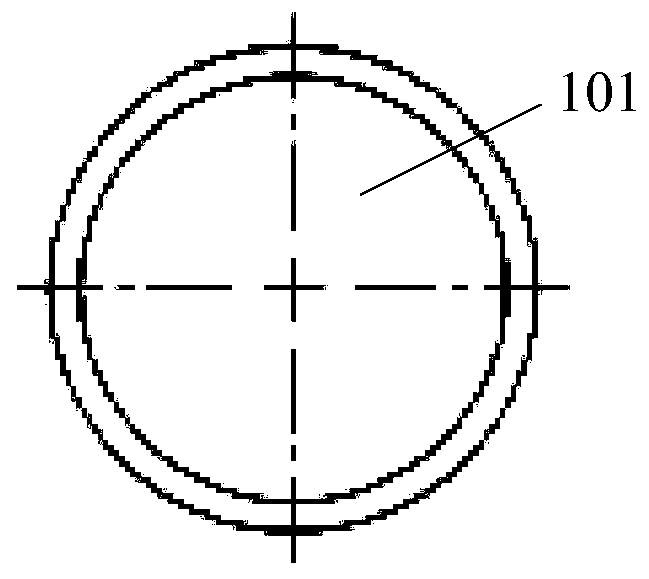

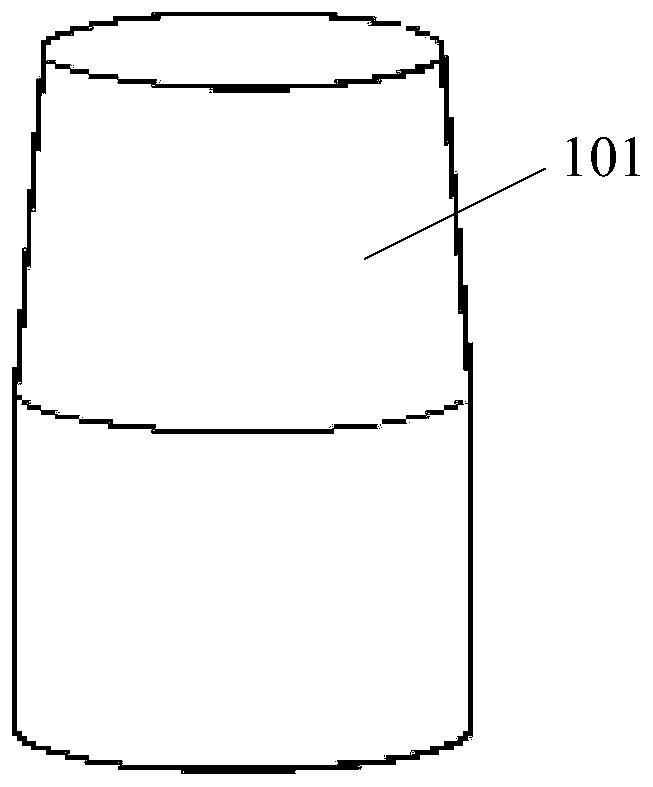

[0049] The hydraulically assisted splitting device provided in this embodiment includes a splitter 101 without a sealing ring 102 . The size of the splitter 101 is set to be smaller, which is convenient to use in the laboratory. It is specifically turned from round steel with a height of 40mm. The diameter of the thicker end of the splitter 101 is 4cm, and the diameter of the end that is turned into a tapered shape is 4cm. 3.5cm, and the height of the tapered part is about 0.8cm, which is 1 / 5 of the height of the entire splitter 101 . The test concrete block is 30cm long, 30cm wide, and 15cm high, and a hole is pre-drilled at 1 / 3 and 2 / 3 of the diagonal, the diameter of the hole is 3.6cm, and the depth is 8cm. After the hole is filled with water, use the splitter 101 provided by this embodiment to block, and then use a hammer to knock and impact the splitter 101, so that the concrete block can be easily broken.

Embodiment 2

[0051] The hydraulically assisted splitting device provided in this embodiment includes a splitter 101 and a sealing ring 102. The splitter 101 is the same as that in Embodiment 1, and the sealing ring 102 is a small ring made of memory alloy. The strength of the tested concrete was increased compared with that of Example 1, and the concrete was 50 cm long, 50 cm wide, and 10 cm high. Open 4 holes evenly at a position 15cm away from one side of the test concrete, each hole has a diameter of 3.6cm, a depth of 7.5cm, and a hole spacing of 10cm. Fill the hole with water, use the splitter 101 and sealing ring 102 provided in this embodiment to block, use a hammer to impact, and the concrete splits smoothly as expected.

Embodiment 3

[0053] The hydraulically assisted splitting device provided in this embodiment includes a splitter 101 without a sealing ring 102 . The splitter 101 is modified on the basis of the splitter 101 of embodiment 1, and the first end of the splitter 101 is continued to be turned, so that its cone angle becomes smaller, and it is easier to block in the concrete cavity; the selected concrete The same as the concrete material in Example 2, all of which are high-strength concrete, 3 holes are uniformly opened at a distance of 15cm from one side of the concrete, each hole has a diameter of 3.6cm, a depth of 7.5cm, and a hole spacing of 12.5cm , fill the hole with colloidal water, block it with a splitter 101, and then use a hammer to impact it. It is found that the concrete is easier to crack than in Example 1. Although the hole spacing is increased compared to Example 1, due to The modified splitter 101 is more likely to block the water in the hole, and the effect is better under impac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com