A method for comprehensively judging the boundary of separate injection technology in separate injection wells

A technology of technical boundaries and determination methods, applied in earthwork drilling and production, wellbore/well components, instruments, etc., can solve the problems of restricting oilfield water injection cost reduction and efficiency increase, heavy workload of on-site production operations, and complicated operation process, etc., to achieve Realize the effect of dispensing qualified long-term effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is further described below in conjunction with accompanying drawing:

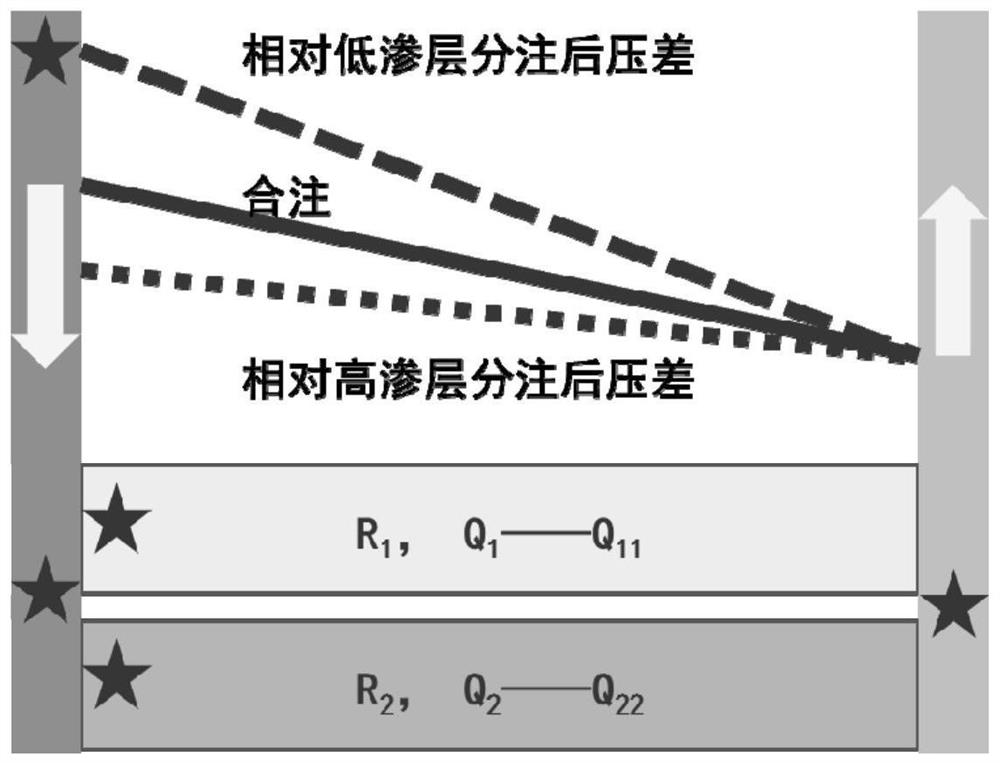

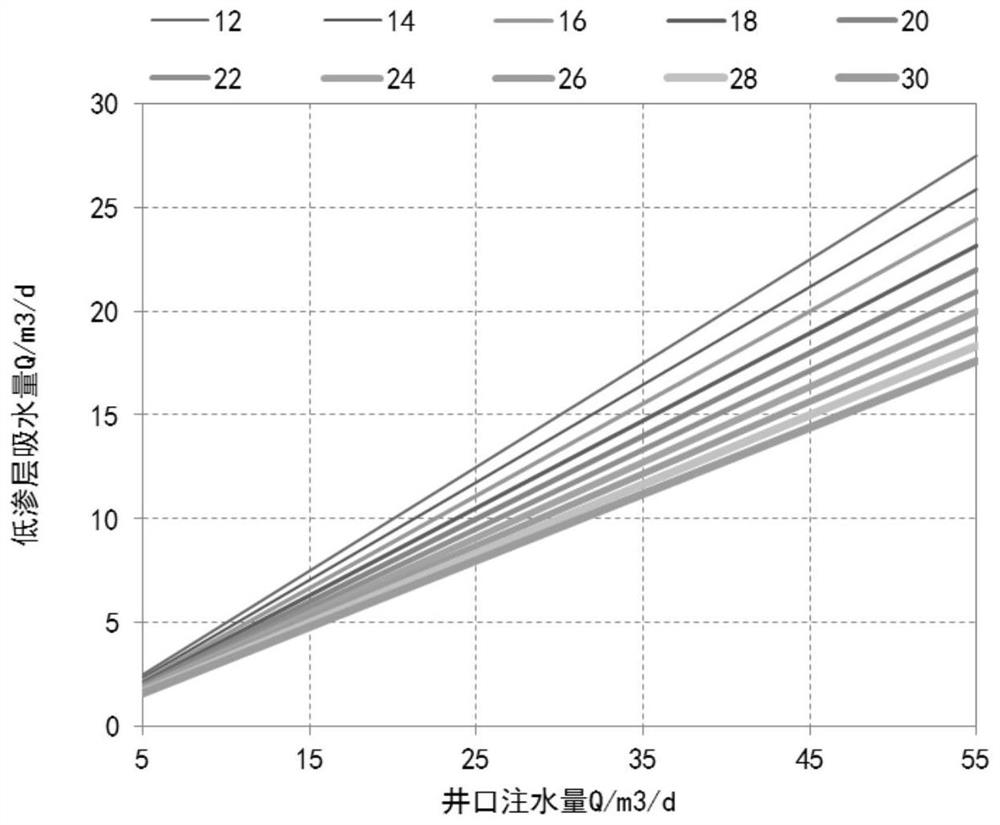

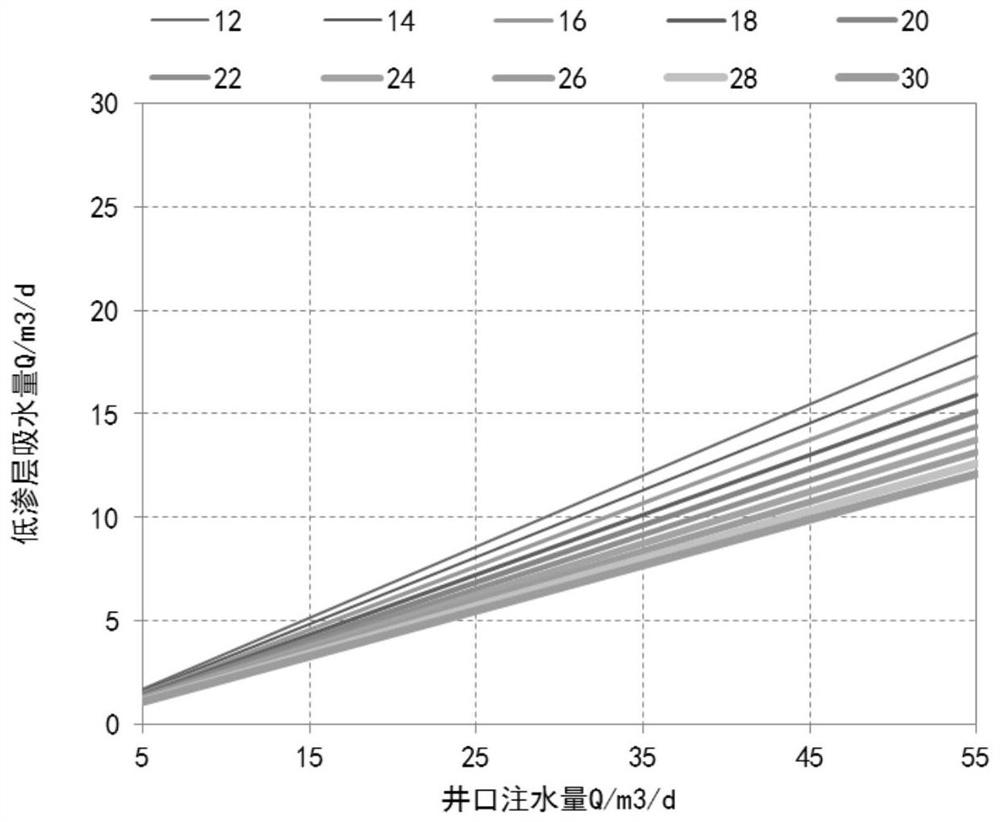

[0049]The present invention provides a method for comprehensively judging the technical boundaries of separate injection wells. The design method for separate injection measurement, adjustment and adjustment adopts an integrated design method of five nodes: ground water injection system, water injection shaft, water distribution nozzle, injection and production well, and oil well shaft. , with "interlayer flow difference" as the characteristic variable, and selective balanced water injection as the design goal, the separate injection boundaries and methods are designed for two types of water injection wells: one is that the water injection pressure is well matched with the reservoir conditions, and the water nozzle has sufficient adjustment The room for water injection can meet the requirements of balanced water absorption. The second category is that the water injection pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com