A Design Method of Bidirectional Axial Flow Pump Impeller Based on Inclined-V Symmetrical Airfoil

A technology of airfoil design and design method, which is applied to components, design optimization/simulation, pumps, etc. of pumping devices for elastic fluids, and can solve problems such as poor flow around, poor cavitation performance, and blade slippage. , to achieve the effect of clear design principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing:

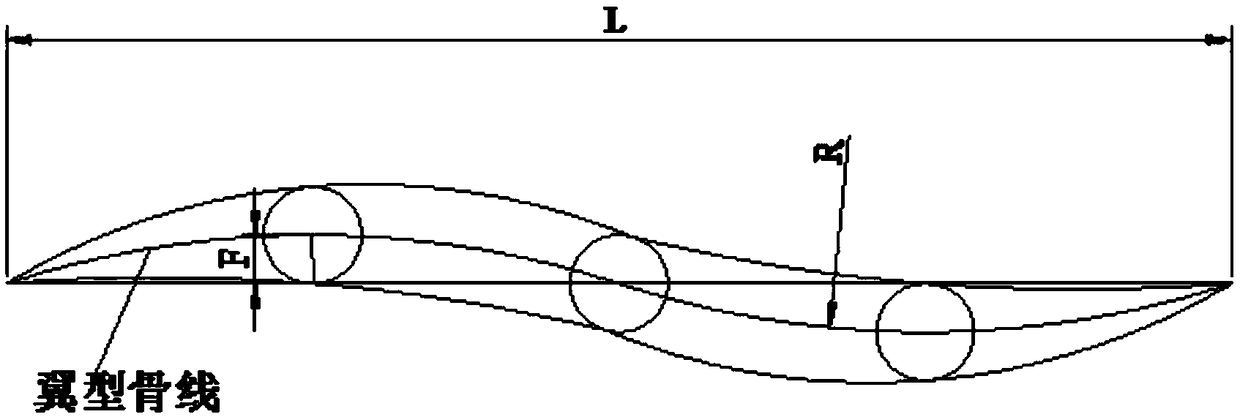

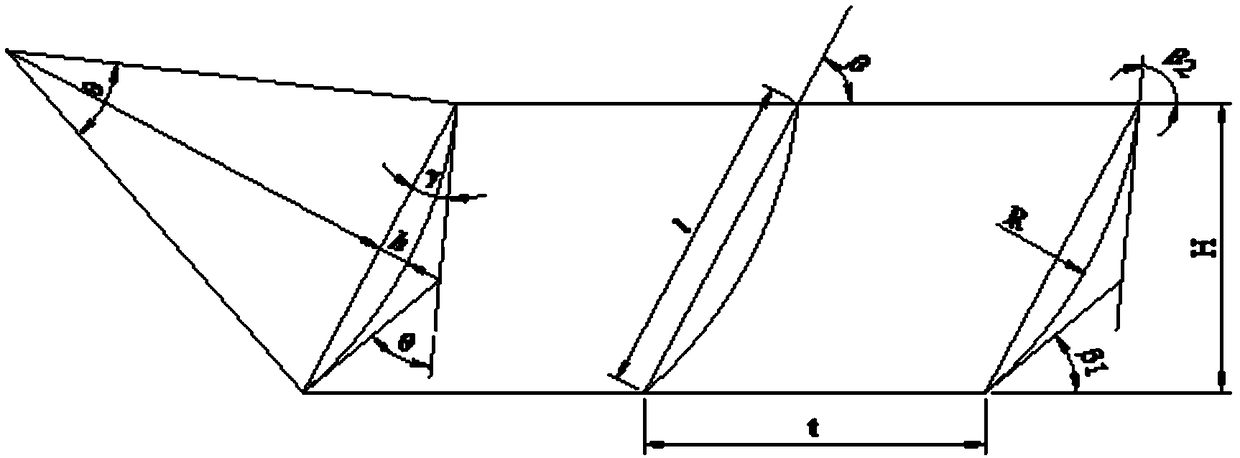

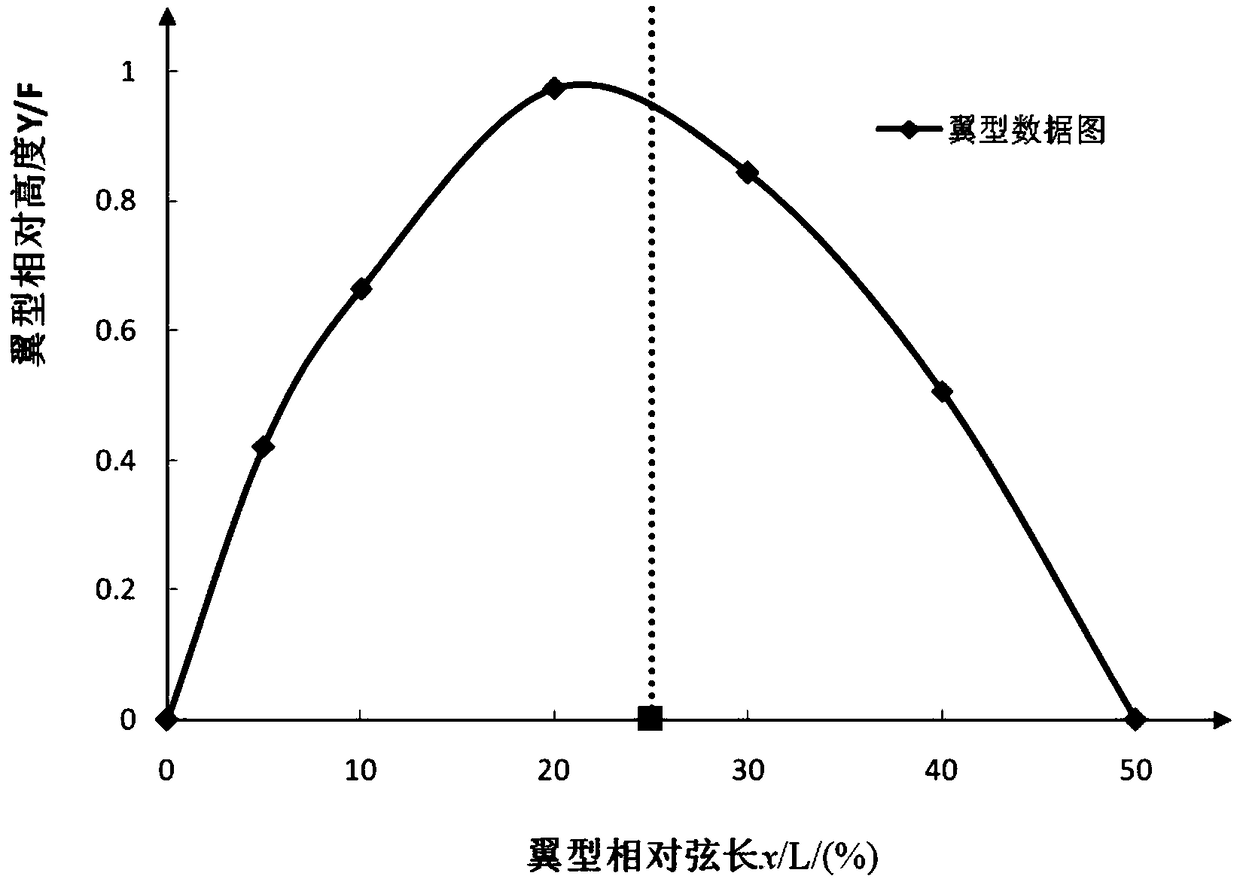

[0050] like Figure 1-8 As shown, a design method of bidirectional axial flow pump impeller based on oblique V symmetrical airfoil, figure 1 L is the chord length of the airfoil; F is the maximum camber of the airfoil; R is the radius of the arc shape; figure 2 Where θ is the central angle of the airfoil bone line, h is the maximum camber of the airfoil, equal to figure 1 F in; l is the chord length of the airfoil bone line, l=L / 2; β 1 , β 2 is the airfoil bone line entry and exit angle; β is the airfoil placement angle; H 2 is the height of the airfoil bone line; t is the grid pitch; γ is the curvature angle of the airfoil bone line.

[0051] According to the arc blade, the relationship between the angles can be known:

[0052] β=β 1 +γ (1)

[0053] β=β 2 -γ (2)

[0054] γ=θ / 2 (3)

[0055] β=(β 1 +β 2 ) / twenty four)

[0056] beta 2 -β 1 = θ (5)

[0057] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com