First sliding and then hinged support and connection method

A connection method and hinge bearing technology, which can be used in building components, earthquake resistance, building types, etc., can solve the problems of poor overall stability of sliding connections and inability to release bending moments, and achieve clear design principles, convenient installation, and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

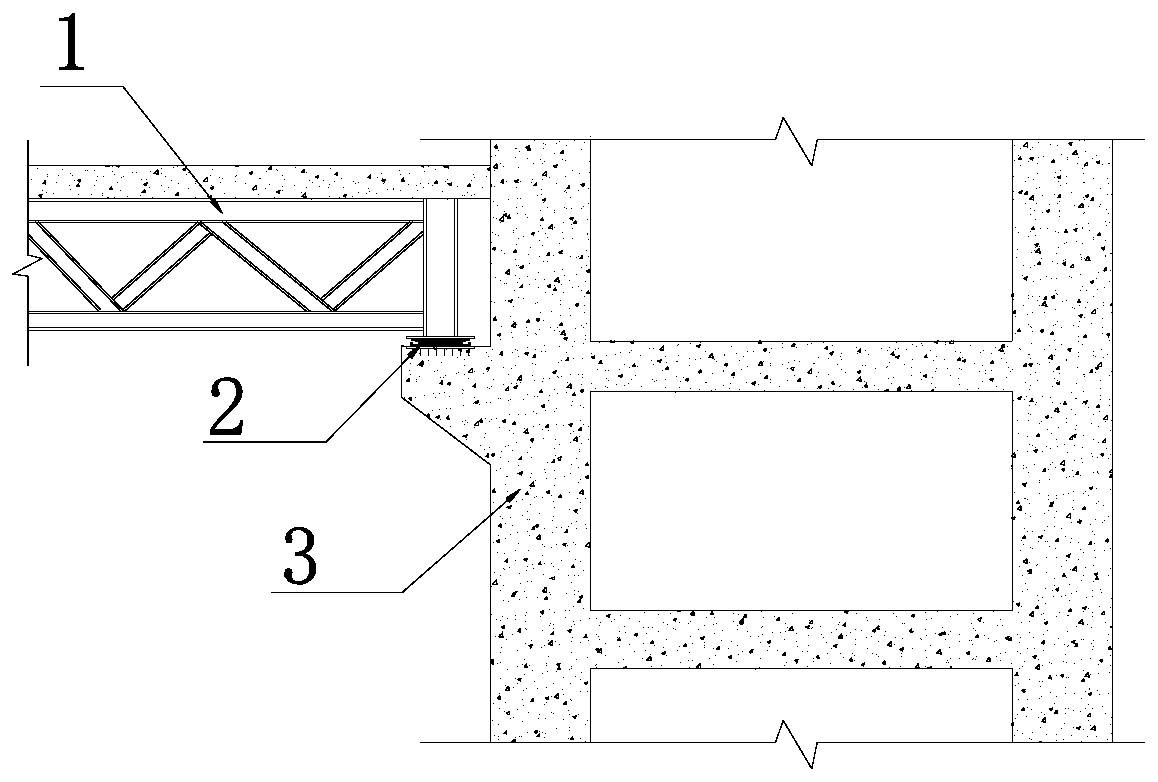

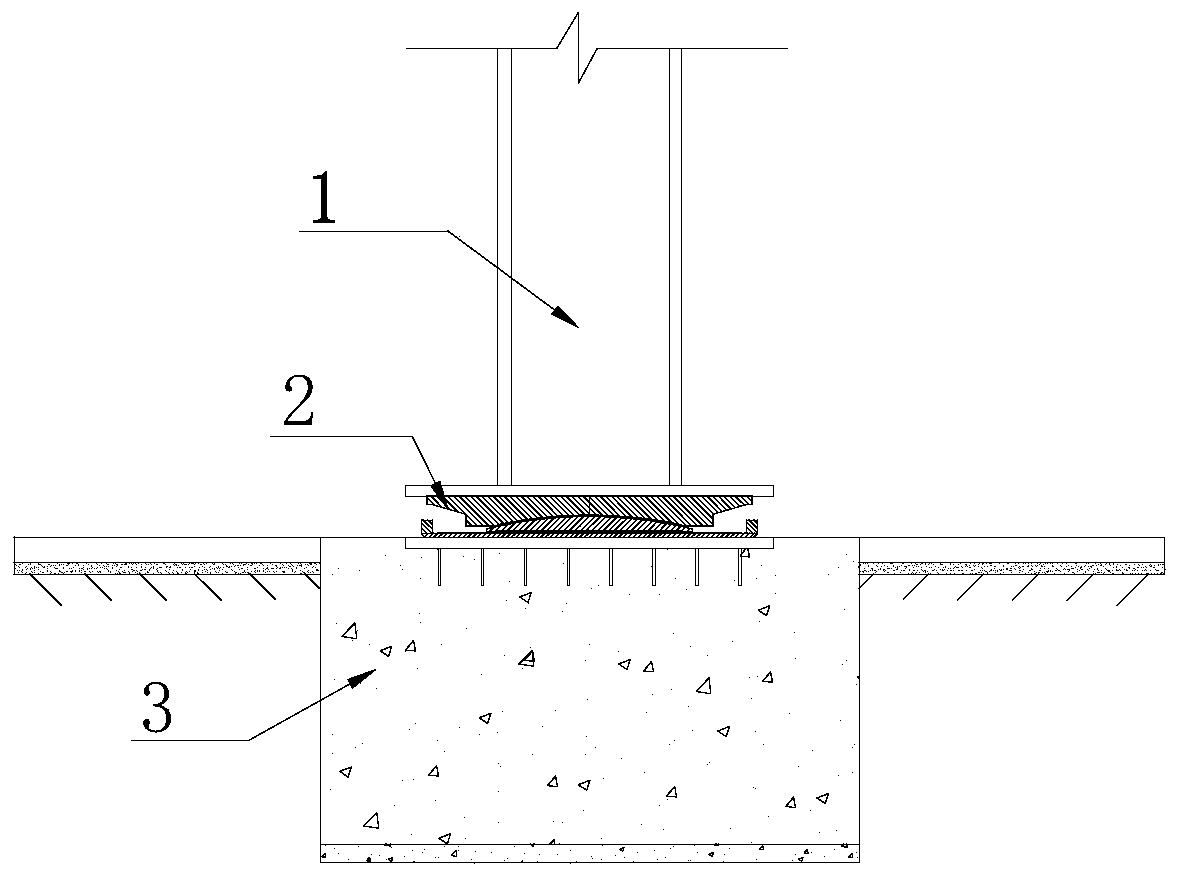

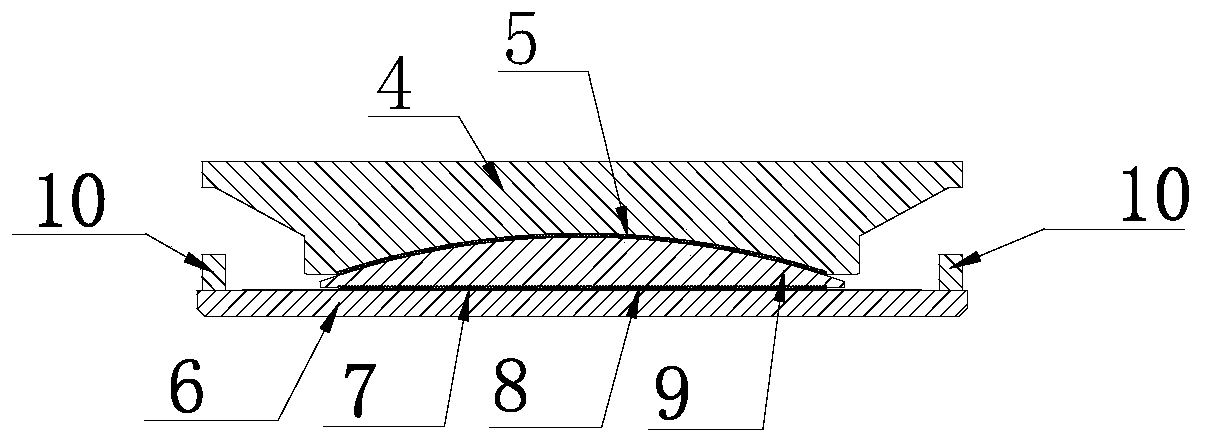

[0027] Such as Figures 1 to 6 As shown, a bearing that slides first and then hinges includes a sliding bearing and a limit plate 11. The sliding bearing 2 includes an upper bearing plate 4, a lower bearing plate 6 and a spherical crown plate 9. The upper bearing plate The support plate 4 is fixed on the upper structure 1, the lower support plate 6 is fixed on the lower structure 3, and the upper side of the lower support plate 6 is surrounded by steel baffles 10 so that the upper side of the lower support plate 6 forms a A chute for the sliding of the spherical crown plate 9, the top of the spherical crown plate 9 is a hemispherical shape, and the bottom surface is a plane, and the upper support plate 4 faces the lower support plate 6 side and is provided with the top of the spherical crown plate 9. matching groove, the bottom of the spherical crown plate 9 is installed in the chute of the lower support plate 6 through the plane slide plate 8 to form the first sliding surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com