Surface mounting type diode

A diode and SMD technology, applied in the field of SMD diodes, can solve problems such as poor optical performance, achieve high refractive index, reduce energy consumption, improve light extraction efficiency and photoelectric replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

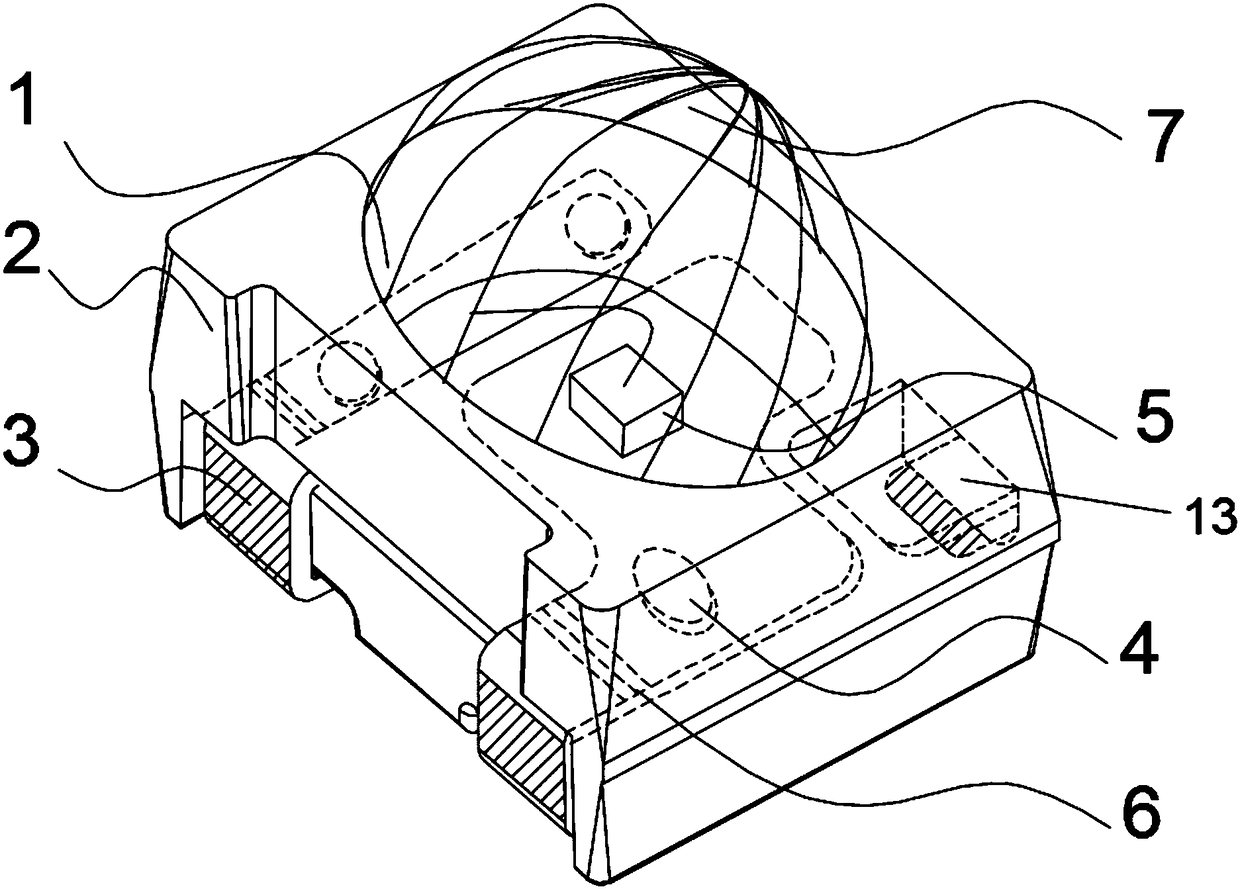

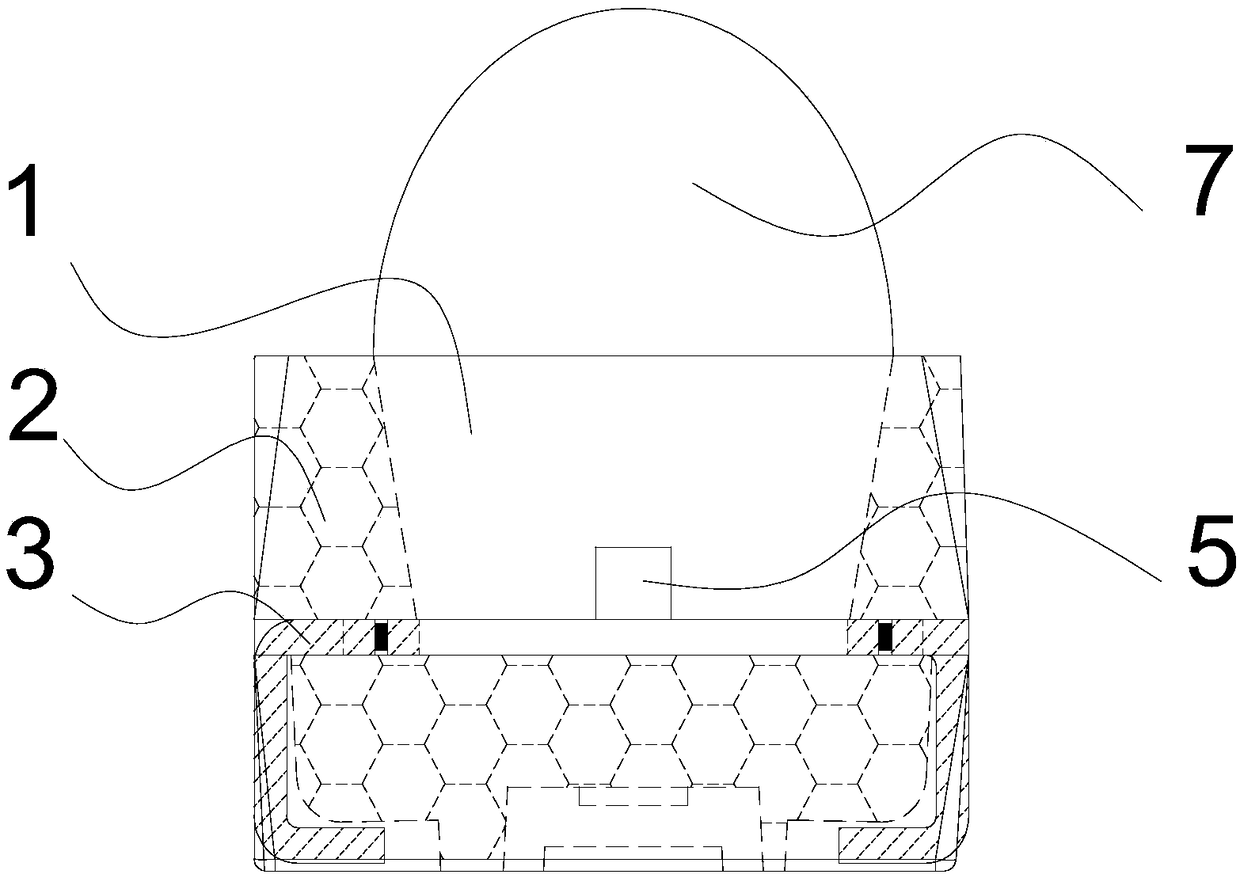

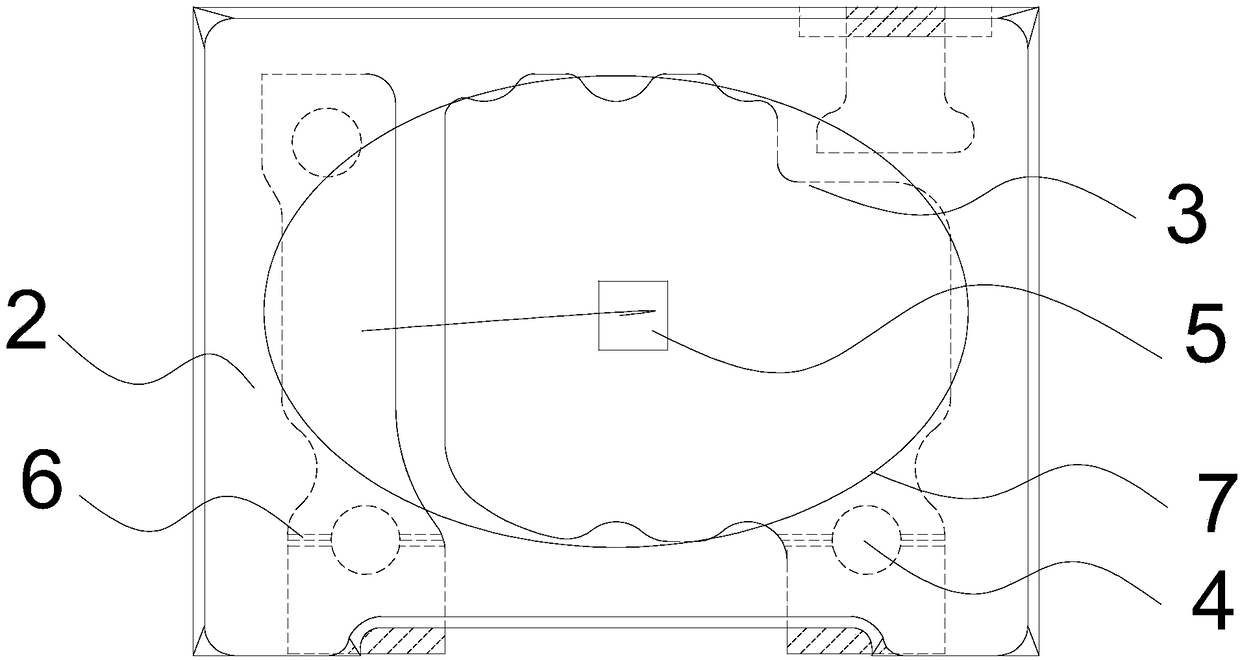

[0047] like Figure 1-6, the present invention provides a chip diode, which is improved on the existing planar packaging structure of semiconductor products. That is to say, the concave reflective groove 1 is injected at the position where the light source is fixed in the original planar package structure-package case 2, and the chip is placed on the bottom of the reflective groove 1, so that the light emitted / received by the chip can pass through the smooth surface. The inner wall of the reflective groove 1 performs concentrated reflection, thereby improving light extraction efficiency and photoelectric conversion efficiency, and reducing energy consumption. That is to say, a concave reflection groove 1 in the plastic casing 2 is used for placing the chip 5 . The chip 5 here may be devices such as visible light / infrared / ultraviolet emitting wafers, photoelectric receiving diodes, and ICs. In addition, the reflection groove 1 is, for example, bowl-shaped, cup-shaped, ellipti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com