Method for blasting high-rise building glass in remote control manner

A high-rise building, remote control technology, applied in the direction of building rescue, life-saving equipment, etc., can solve problems such as affecting fire protection, wall glass cannot be blasted in time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

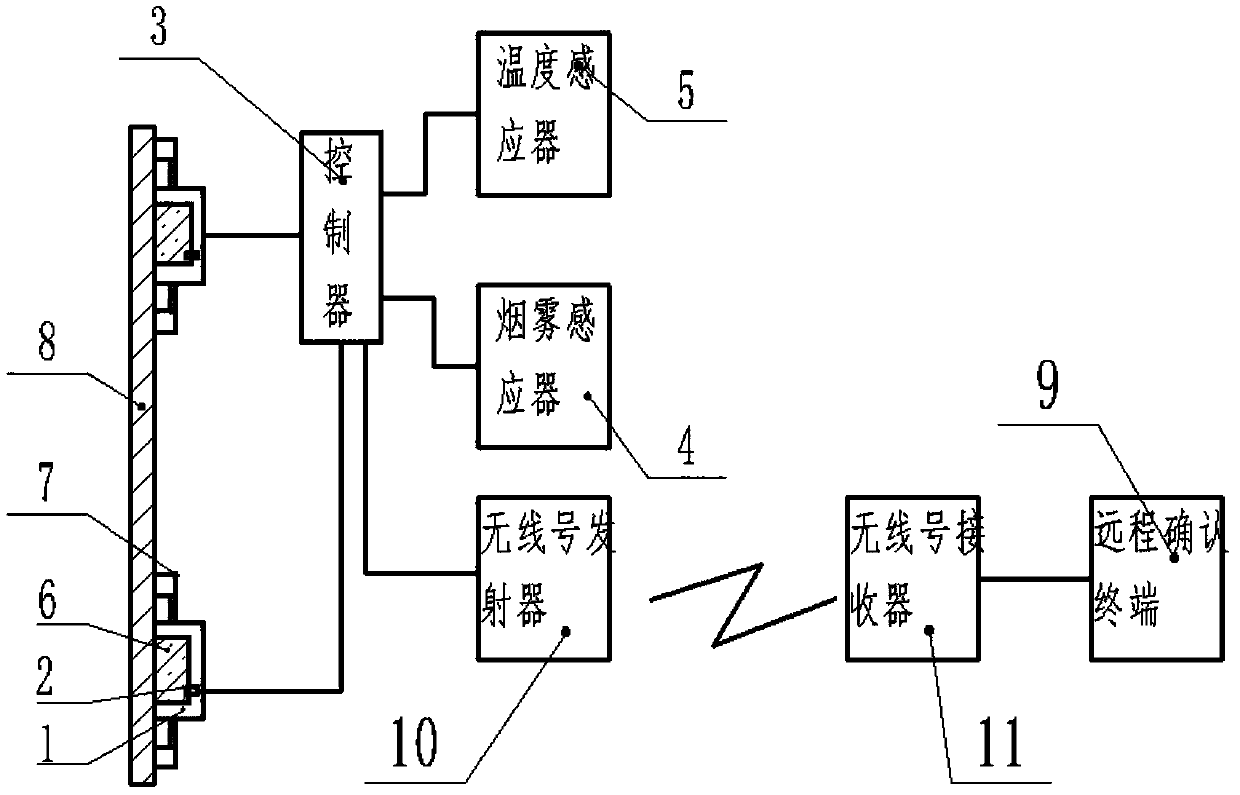

[0019] like figure 1 As shown, the present invention blasts high-rise building glass by remote control, including a propellant cavity 1, a detonating core 2, a controller 3, a smoke sensor 4 and a temperature sensor 5, and the propellant cavity 1 is a groove structure , the gunpowder cavity 1 is equipped with gunpowder 6, and the gunpowder cavity 1 is surrounded by a plurality of suction cup holders 7, the gunpowder cavity 1 is adsorbed on the glass 8 through the suction cup holders 7, and the opening of the gunpowder cavity 1 corresponds to the glass 8 , a detonating core 2 for detonating the propellant 6 is provided in the propellant cavity 1, the detonating core 2 is connected to a controller 3, and the controller 3 is connected to a smoke sensor 4 and a temperature sensor 5 respectively. The controller (3) is connected with a wireless signal transmitter (10), and the remote confirmation terminal (9) is connected with a wireless signal receiver (11).

[0020] Four corners ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com