Magnesian fire-proof explosion-proof oil tank

A magnesia, oil tank technology, applied in the field of oil tanks, can solve the problems of unsightly oil tanks, low heat insulation and heat preservation performance, easy corrosion, etc., and achieve the effects of high wear resistance, good shock resistance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

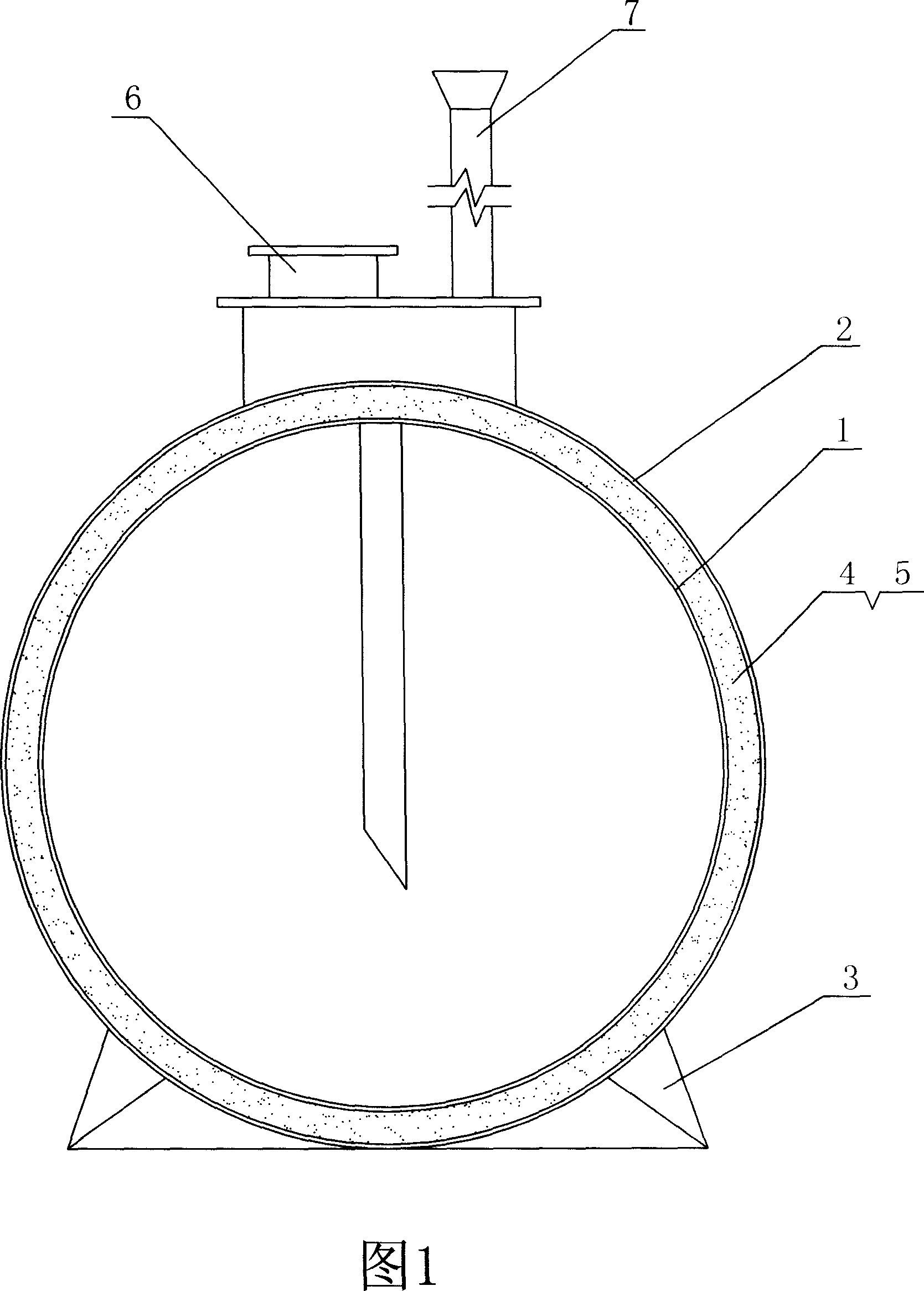

[0021] A magnesium flameproof and explosion-proof oil tank includes an inner tank body 1, an outer tank body 2 and a support 3 fixed on the outer tank body 2. The inner tank body 1 is arranged in the outer tank body 2, and there is a gap 4 between the outer tank body 2 and the inner tank body 1, and the gap 4 is filled with magnesia 5, and the filling natural density is 0.19g / cm 3 , bulk density 0.25g / cm 3 . Magnesia contains 80-85% magnesium oxide, and the particle size is ≥140 mesh. An exhaust valve 6 and a breathing valve 7 are installed on the oil tank body. The inner tank body 1 is an inner tank body made of steel plate, and the outer tank body 2 is an outer tank body made of epoxy resin.

Embodiment 2

[0023] Embodiment 2 is basically the same as Embodiment 1, except that what is filled in the gap 4 is a mixture of magnesia and expanded perlite, and its batching ratio is: magnesia 100kg, expanded perlite 250kg, expanded perlite particle size ≥ 140 head.

Embodiment 3

[0025] The difference between the third embodiment and the first or second embodiment is that the outer tank body 2 is a double-layer composite tank body. Its inner layer is a magnesia inner layer tank body, which is composed of magnesia containing 80-85% of magnesium oxide, 100kg of magnesia with a particle size of ≥140 mesh, 70kg of magnesium chloride solution containing ≥45% of magnesium chloride, modifier A 1 0.6kg of mixed slurry is molded through a mold, and after curing, an epoxy resin outer tank is compounded on the magnesium inner tank, that is, the glass fiber reinforced plastic outer tank. Both the magnesium inner layer tank body and the epoxy resin outer layer tank body are embedded with glass fiber mesh cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com