Self-tightening multi-layer supercritical extraction kettle

A supercritical, extraction kettle technology, which is applied in solvent extraction, solid solvent extraction, chemical instruments and methods, etc., can solve the problems of rapid escape and secondary loosening of extractants, save manpower and material resources, improve extraction efficiency, and improve extraction efficiency. The effect of filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

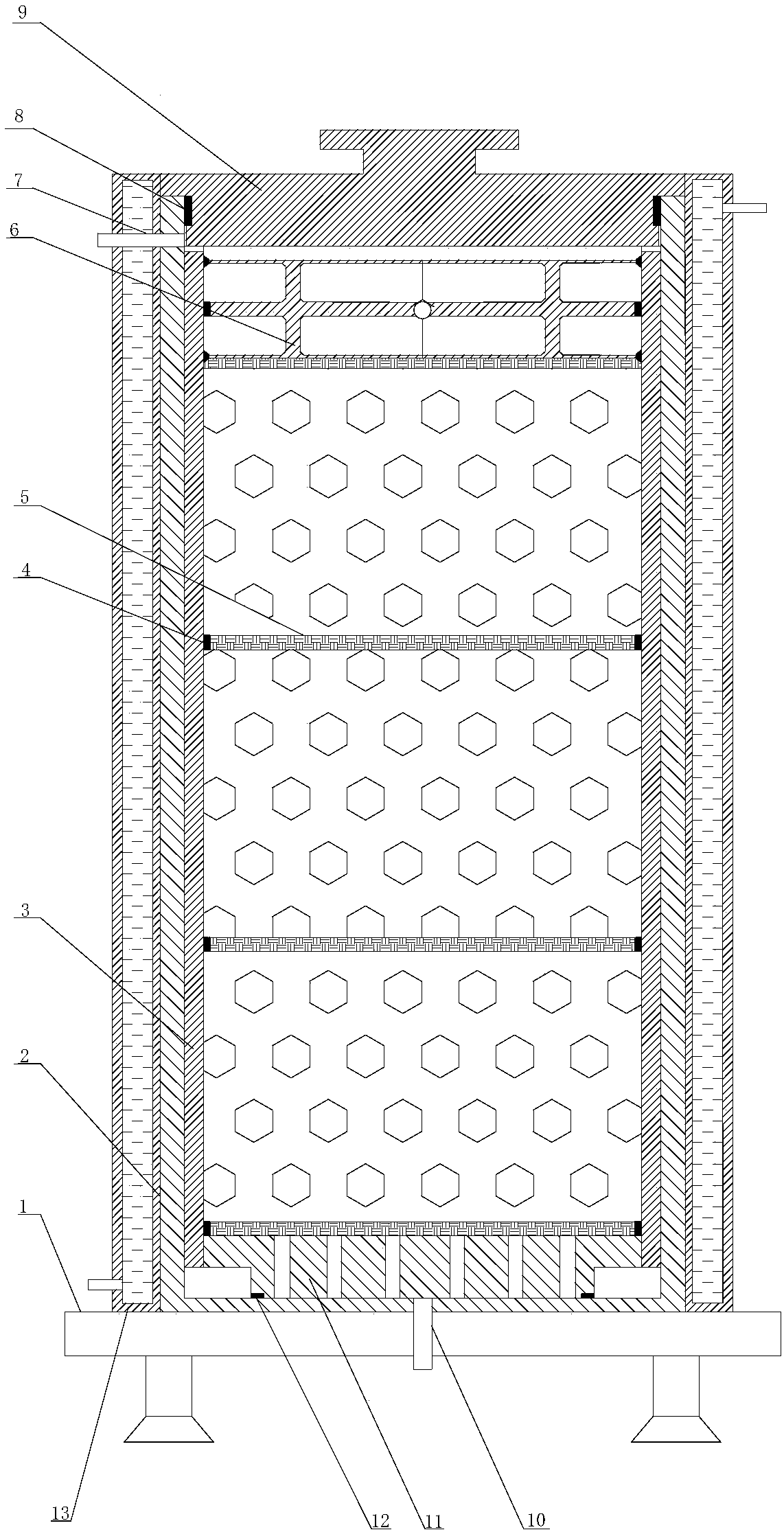

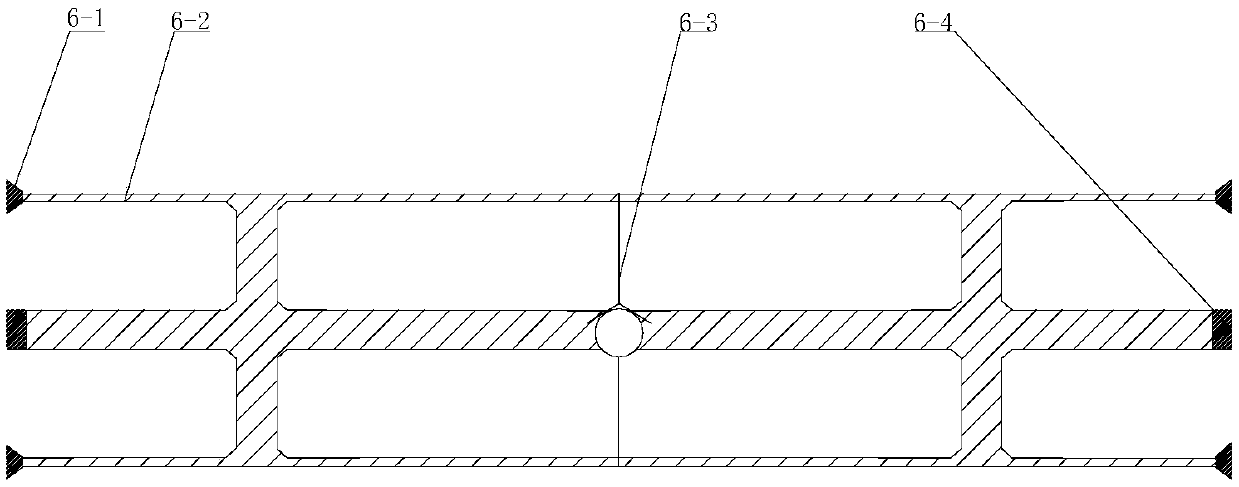

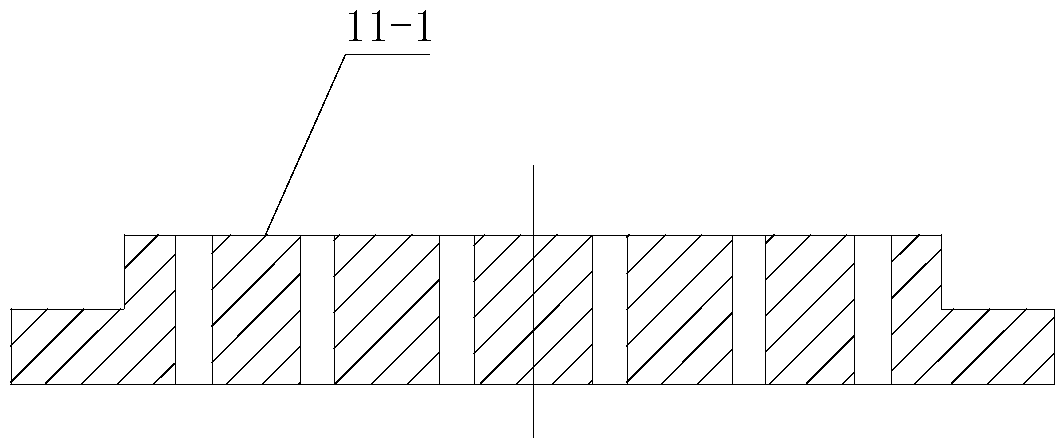

[0025] exist figure 1 , 2 Among them, a self-tightening multi-layer supercritical extraction kettle of the present invention, a water bath tube 13 is installed on the bracket 1, the side wall of the water bath tube 13 is processed into a hollow structure, water is housed in the hollow structure, and the lower end of the side wall of the water bath tube 13 is installed with a The water inlet pipe connected with the side wall of the water bath cylinder 13, the upper end is installed with the water outlet pipe connected with the side wall of the water bath cylinder 13, the outer cylinder 2 is installed in the water bath cylinder 17, and the bottom of the outer cylinder 2 is processed with an oil outlet pipe that penetrates the bracket 1 10. The oil outlet pipe 10 is used to discharge and collect the extracted oil. An inner cylinder 3 is installed inside the outer cylinder 2. The inner cylinder 3 is a structure with upper and lower openings. The inner wall of the inner cylinder 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com