Full-automatic processing equipment

A processing equipment, fully automated technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low processing efficiency, low degree of automation, low fluency, etc., to achieve high processing efficiency, high degree of automation, smoothness high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

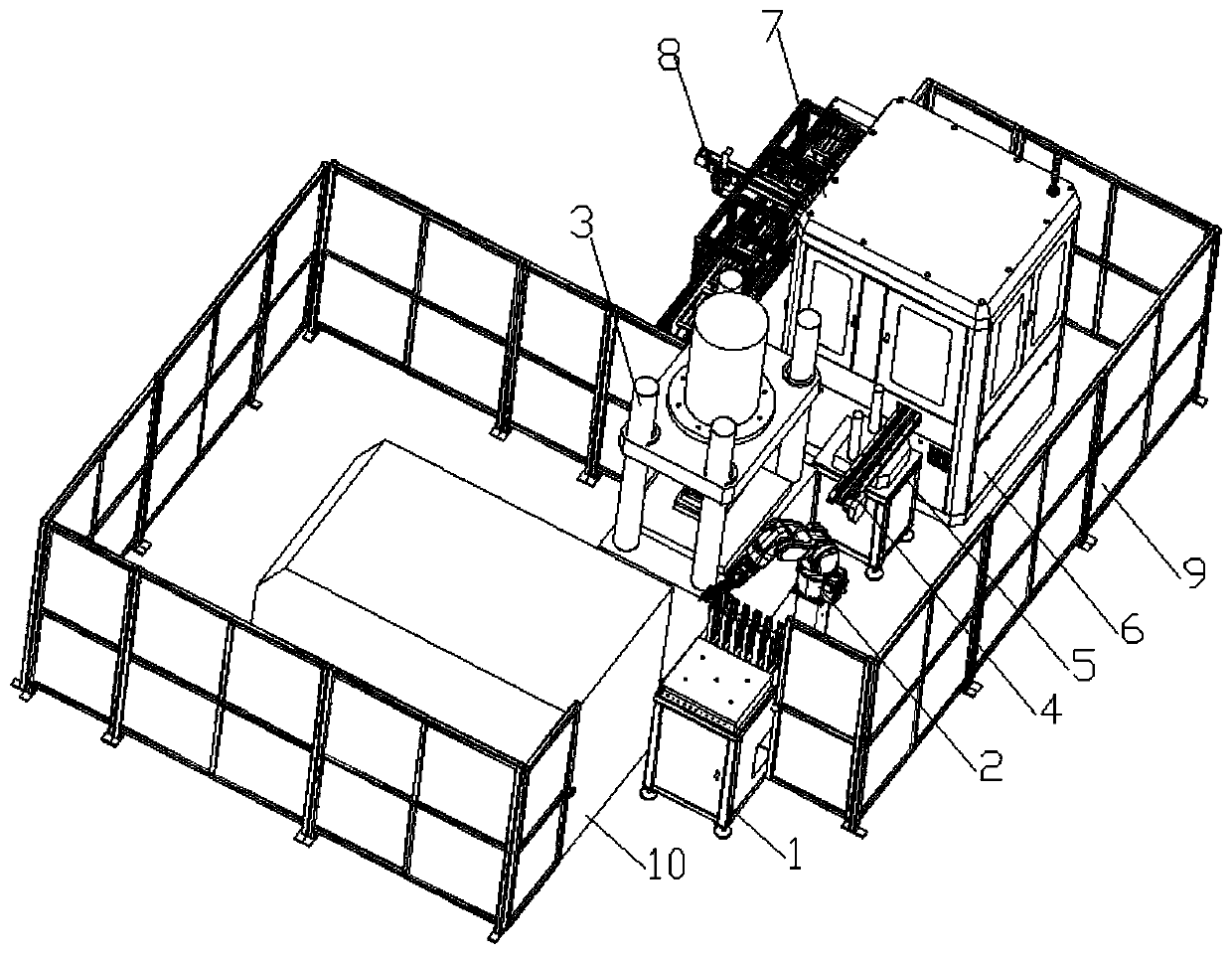

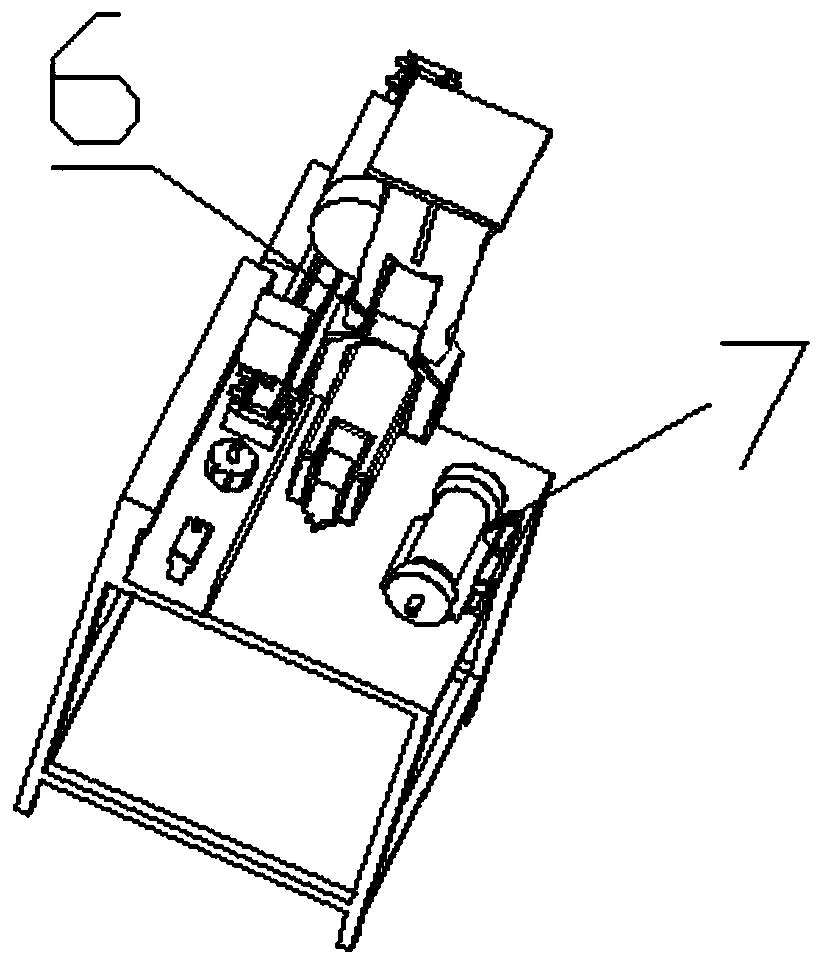

[0017] As a preferred embodiment of the present invention, the hydraulic mechanism 3, the lettering mechanism 4 and the deburring and chamfering mechanism 6 are sequentially arranged in the guardrail 9 from front to back, and the deburring and chamfering mechanism 6, the polishing mechanism 7 and the The receiving mechanism 8 is sequentially arranged in the guardrail 9 from right to left.

[0018] As a preferred embodiment of the present invention, an oil tank 10 for supplying oil to the hydraulic mechanism 3 is installed inside the guardrail 9 .

[0019] Working principle: Firstly, the handling manipulator 2 takes out the materials on the loading platform and puts them into the hydraulic mechanism 3 for pressing and forming, and then the transport trolley 5 transports the pressed and formed materials to the lettering mechanism 4 for typing and deburring and chamfering Deburring in the mechanism 6, and then the polishing manipulator sends the deburred material to the polishing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap