Combination processing production equipment for cantilever supporting pipe and positioning pipe

A combination of processing and production equipment technology, applied in metal processing equipment, positioning devices, metal processing, etc., can solve the problems of high manual participation and difficulty in ensuring precision, and achieve low labor costs, good processing accuracy, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific examples.

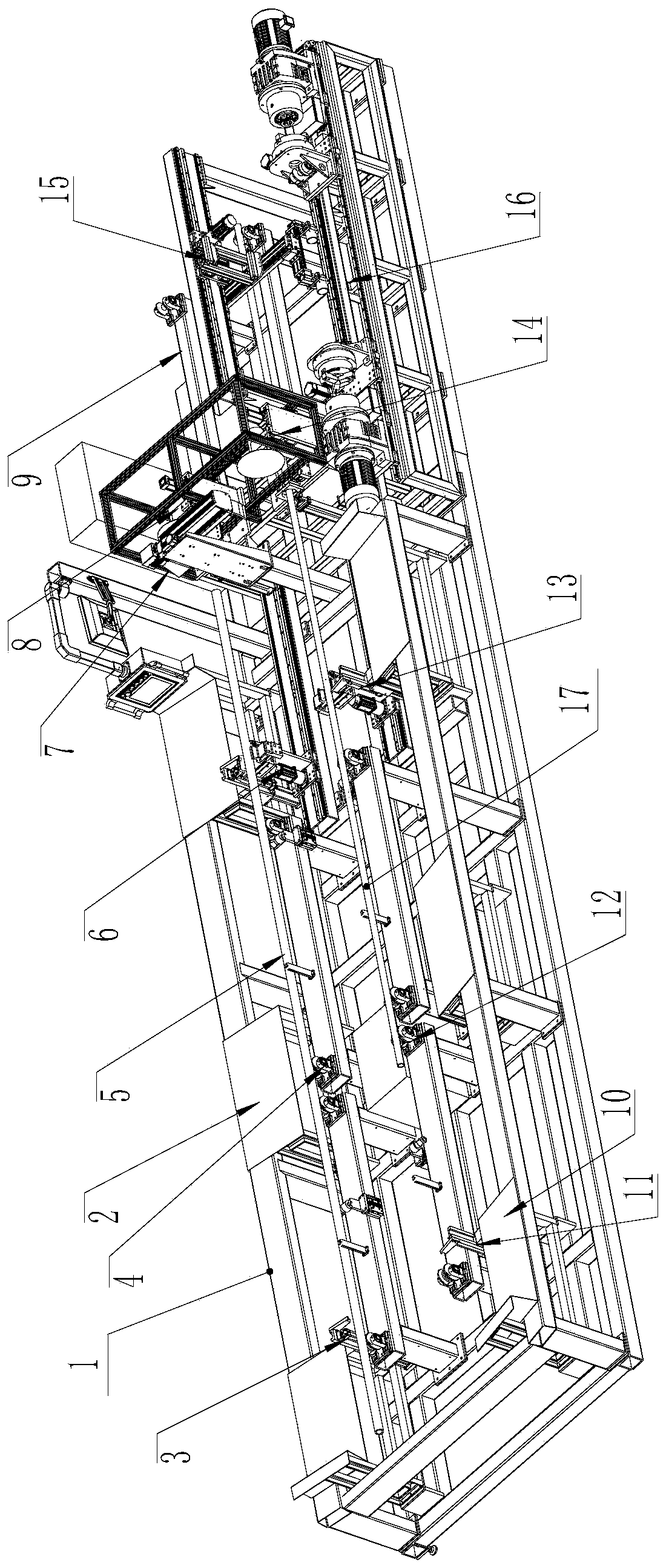

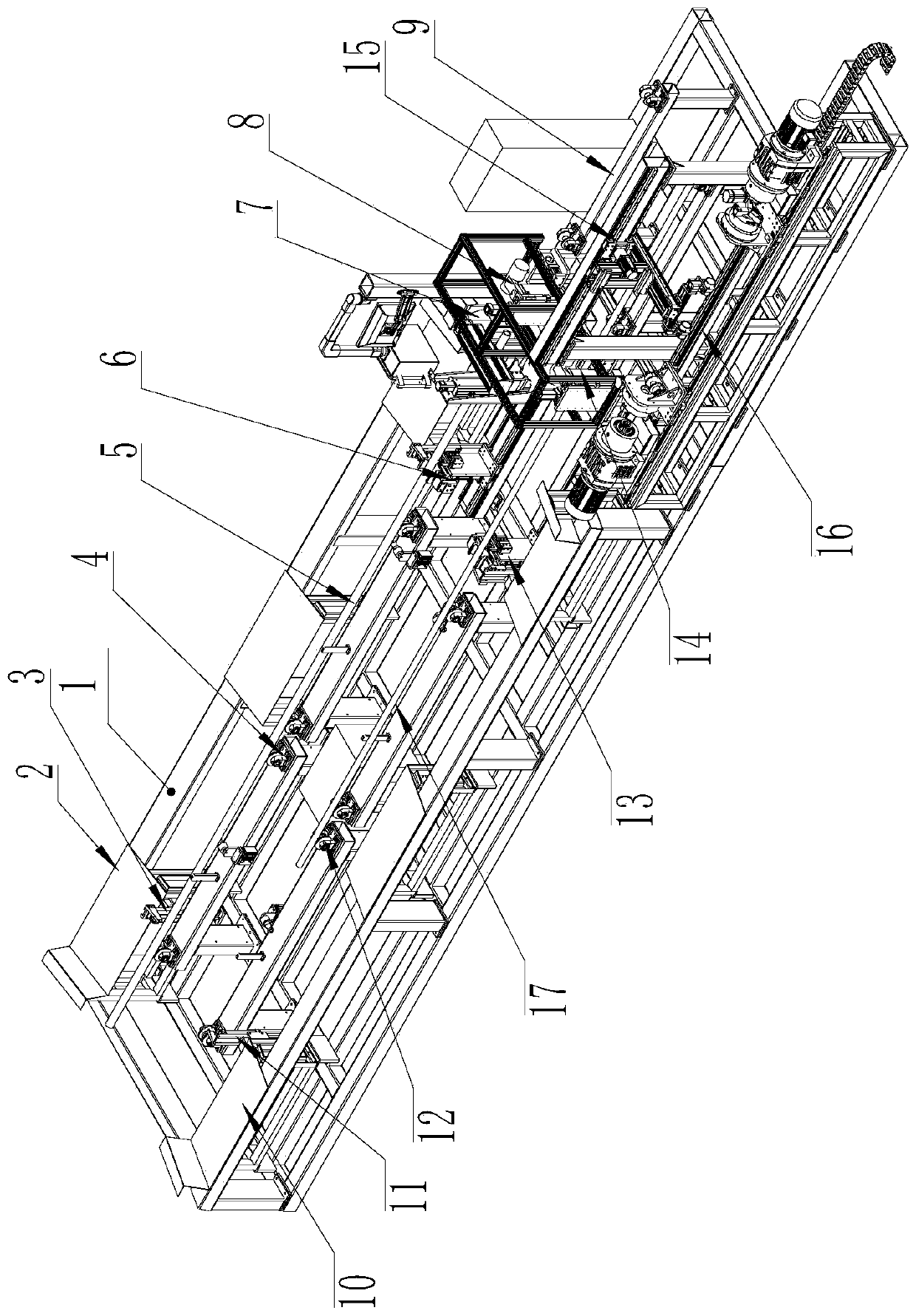

[0034] Such as Figure 1 to Figure 9 As shown, a combined processing and production equipment of a wrist-arm support tube and a positioning tube includes a frame 1, and a support tube processing unit and a positioning tube processing unit are respectively installed on the frame 1;

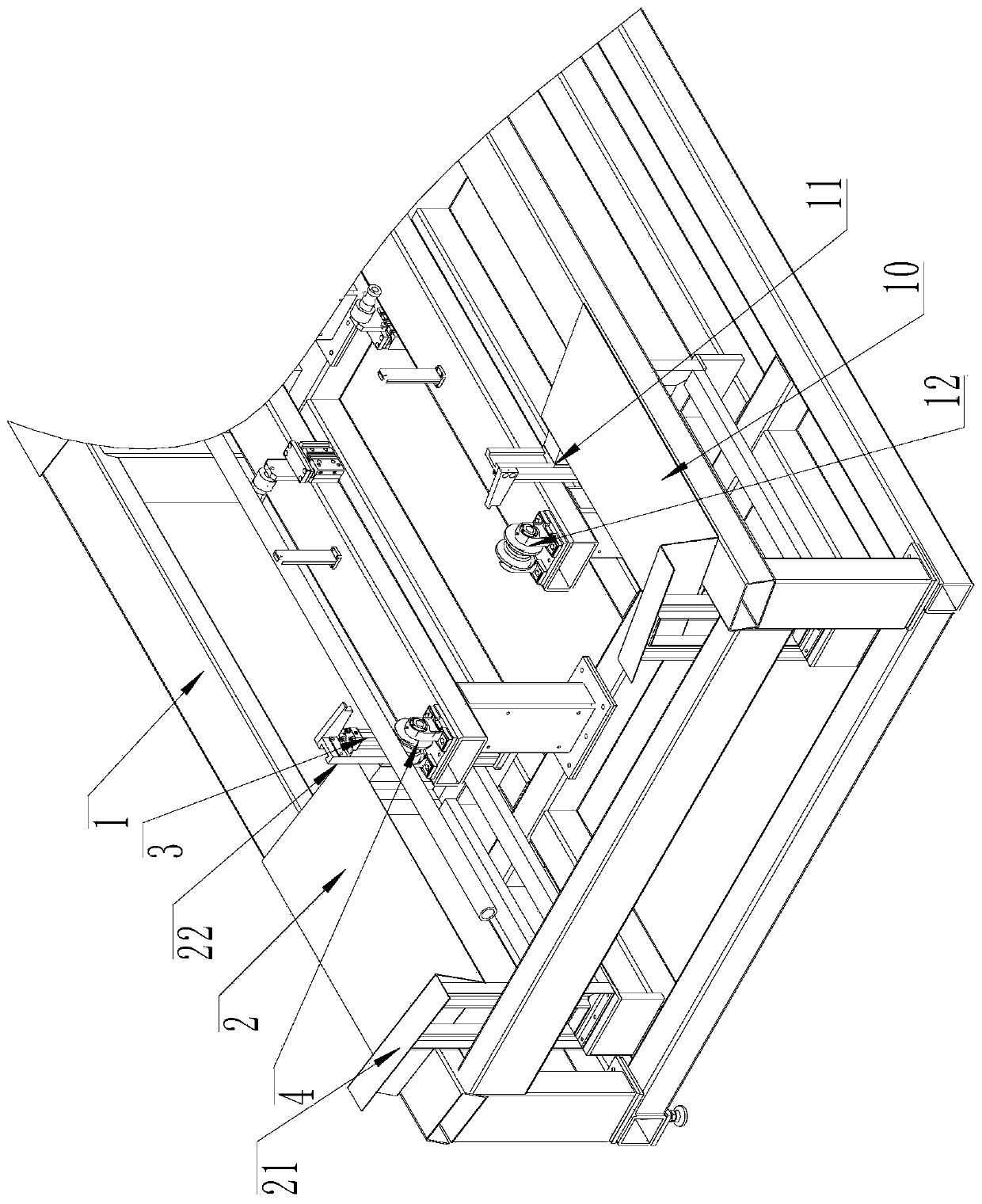

[0035] The support tube processing unit includes a first storage device 2 for storing the support tube raw material 5 tubes, the first storage device 2 is fixed on one side of the frame 1, the first storage device 2 and the second storage device 10 The same structure as above, the first storage device 2 includes several storage units, the storage units are arranged in multiples so that raw materials of different lengths can be stored. And each material storage unit all comprises an inclined stocking plate 22, is positioned at the low end of stocking plate 22 and is provided with retaining bracket 23...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap