Robot instruction motion control system

A technology of command action and control system, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of weak processing ability, simple structure, and difficulty in decentralized functions of the central controller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

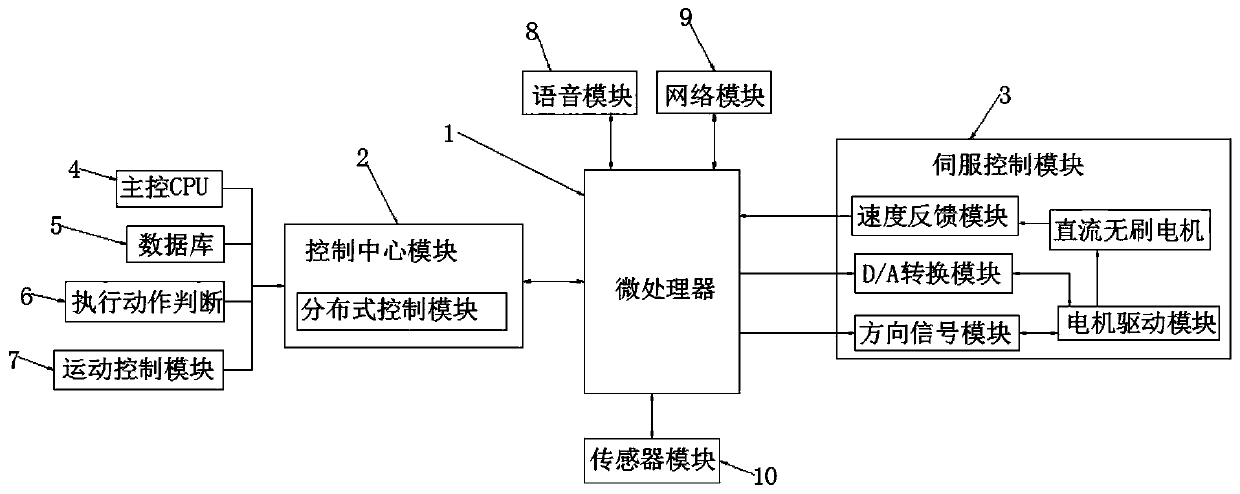

Embodiment 1

[0026] Embodiment one, such as figure 1 As shown, a robot command action control system according to an embodiment of the present invention includes an embedded microprocessor (S3C2410 microprocessor) 1, a control center module 2, and a servo control module 3. The control center module 2 and the servo The control modules 3 are all connected to the microprocessor 1, wherein the control center module 2 is a distributed control module, and the distributed control module includes a main control CPU 4, a database 5, an execution action judgment 6 and a motion control module 7 , the output terminals of the main control CPU4, the database 5, the execution action judgment 6 and the motion control module 7 are all connected to the input terminals of the distributed control module, and the microprocessor 1 is connected with Voice module 8, network module 9 and sensor module 10, the output end and the input end of described voice module 8, described network module 9 and described sensor ...

Embodiment 2

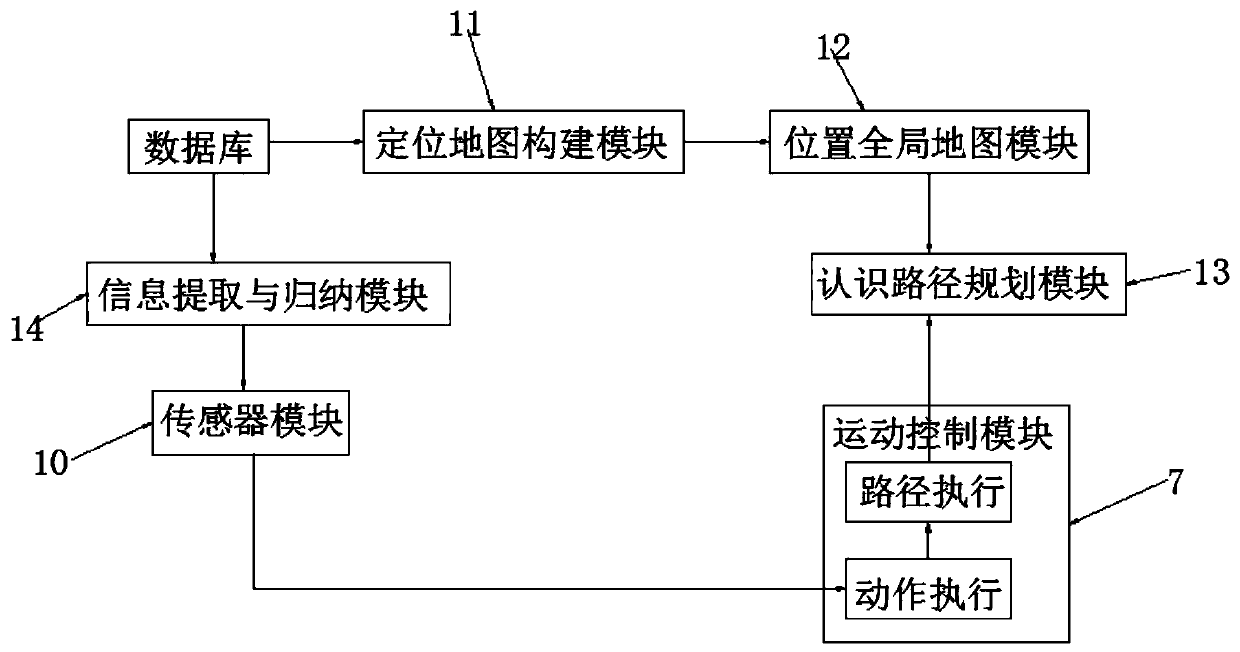

[0027] Embodiment two, such as figure 2 As shown, the output end of the database 5 is connected with a positioning map construction module 11, the output end of the positioning map construction module 11 is connected with a position global map module 12, and the output end of the position global map module 12 is connected with a recognition path Planning module 13, the output end of described database 5 is connected with information extraction and induction module 14, and the output end of described information extraction and induction module 14 is connected with the input end of described sensor module 10, and described motion control module 7 comprises path execution and action execution, wherein the input end of the action execution is connected to the output end of the sensor module 10, the output end of the action execution is connected to the input end of the path execution, and the output end of the path execution is connected to the The input end of the cognitive path...

Embodiment 3

[0028] Embodiment 3, the sensor module 10 includes an ultrasonic sensor, a photoelectric sensor, a digital magnetic compass and an inclination sensor, wherein the ultrasonic sensor and the photoelectric sensor are combined to receive obstacle information detected during the operation of the robot, The digital magnetic compass and the inclination sensor are connected with the receiving module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com