Automatic control system with computer-vision bar code identification function

A barcode recognition and computer vision technology, applied in computer parts, computing, labeling machines, etc., can solve the problems of high cost of industrial computer, increased cost of labeling machines, and inability to realize automation, so as to avoid label errors and high recognition The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

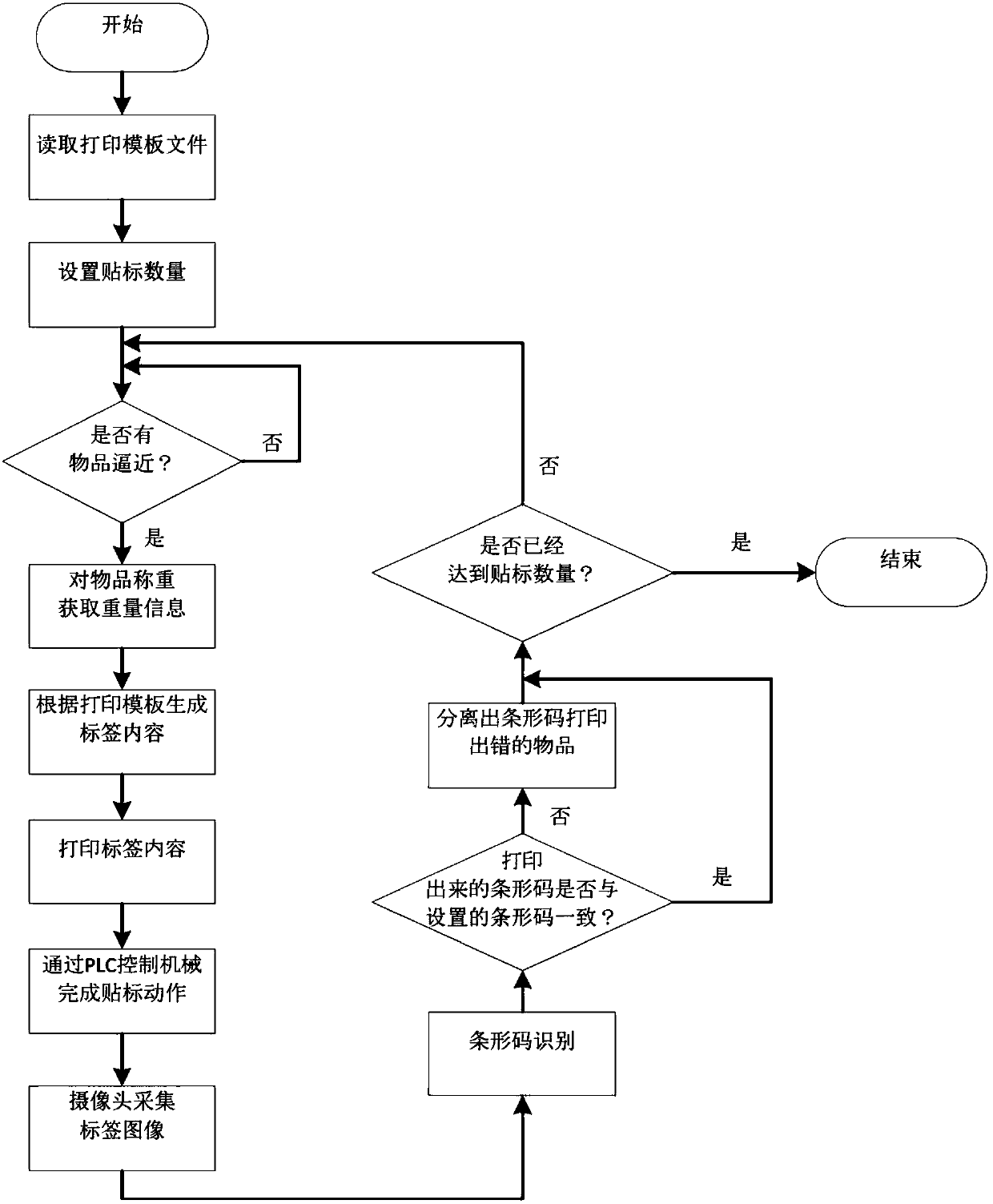

[0029] refer to figure 1 , a kind of automatic control method with computer vision bar code recognition function, described method comprises the following steps:

[0030] Pre-set the requirements for printing barcodes, including reading the printing template file and setting the labeling quantity;

[0031] After judging that an item is approaching, use the weight information acquisition module to weigh the item, generate the label content with a graphic identifier according to the weight information of the item according to the print template file, print the label, and attach the label to the item;

[0032] Collect the label image through the camera, and judge whether the information of the label file is consistent with the label content set in the previous step through the control system;

[0033] Separation of mislabeled items;

[0034] Repeat the above steps until the items with correct label content reach the set labeling quantity.

[0035] Further, the print template f...

Embodiment 2

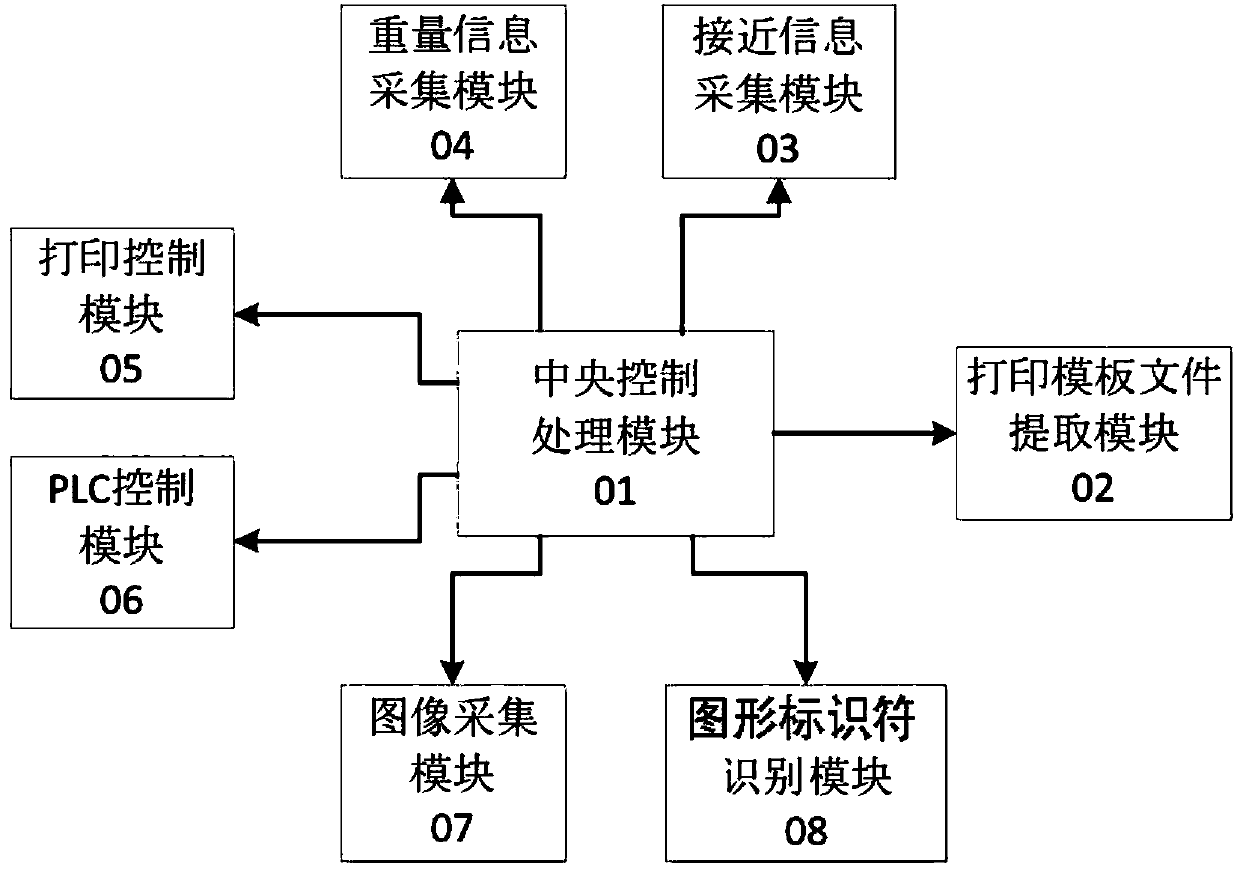

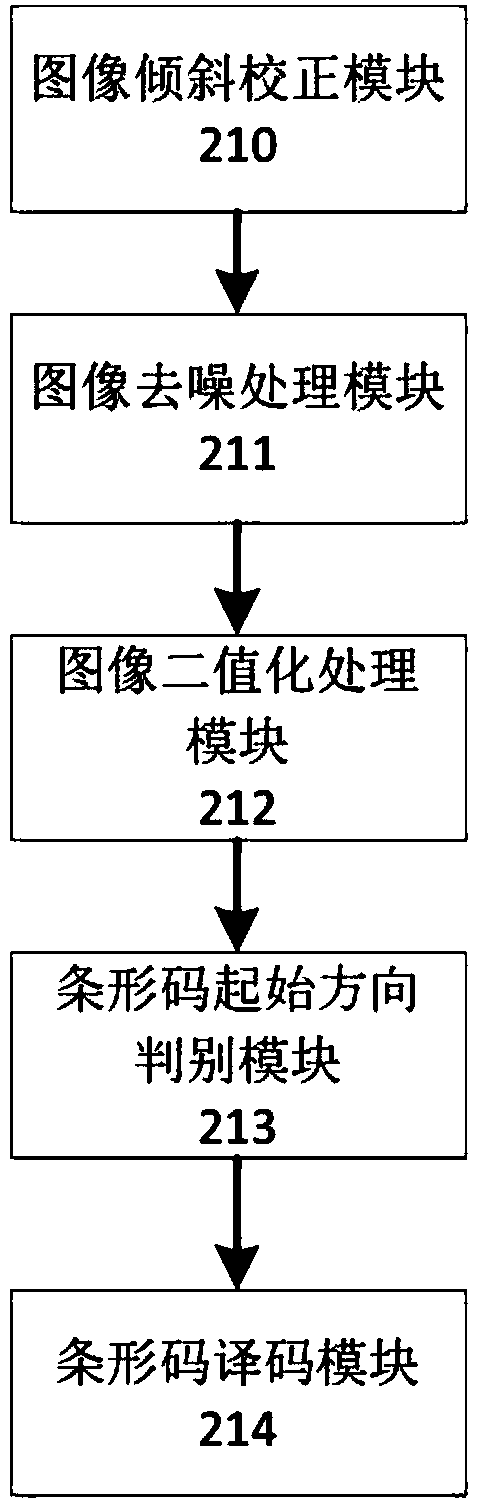

[0044] refer to Figure 2-3 , an automatic control system with a computer vision barcode recognition function, which can implement the automatic control method in the first embodiment, including a central control processing module 01, the central control processing module 01 is connected with a print template file extraction module 02, proximity information Acquisition module 03, weight information acquisition module 04, print control module 05, PLC control module 06, image acquisition module 07, graphic identifier identification module 08, described graphic identifier identification module 08 comprises: image tilt correction module 210, image removal Noise processing module 211, image binarization module 212, graphic identifier start direction discrimination module 213, graphic identifier decoding module 214; the central control processing module 01 can print the tape according to the information sent by the weight information collection module 04 Label with weight informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com