Gypsum powder dry material feeding control method and device

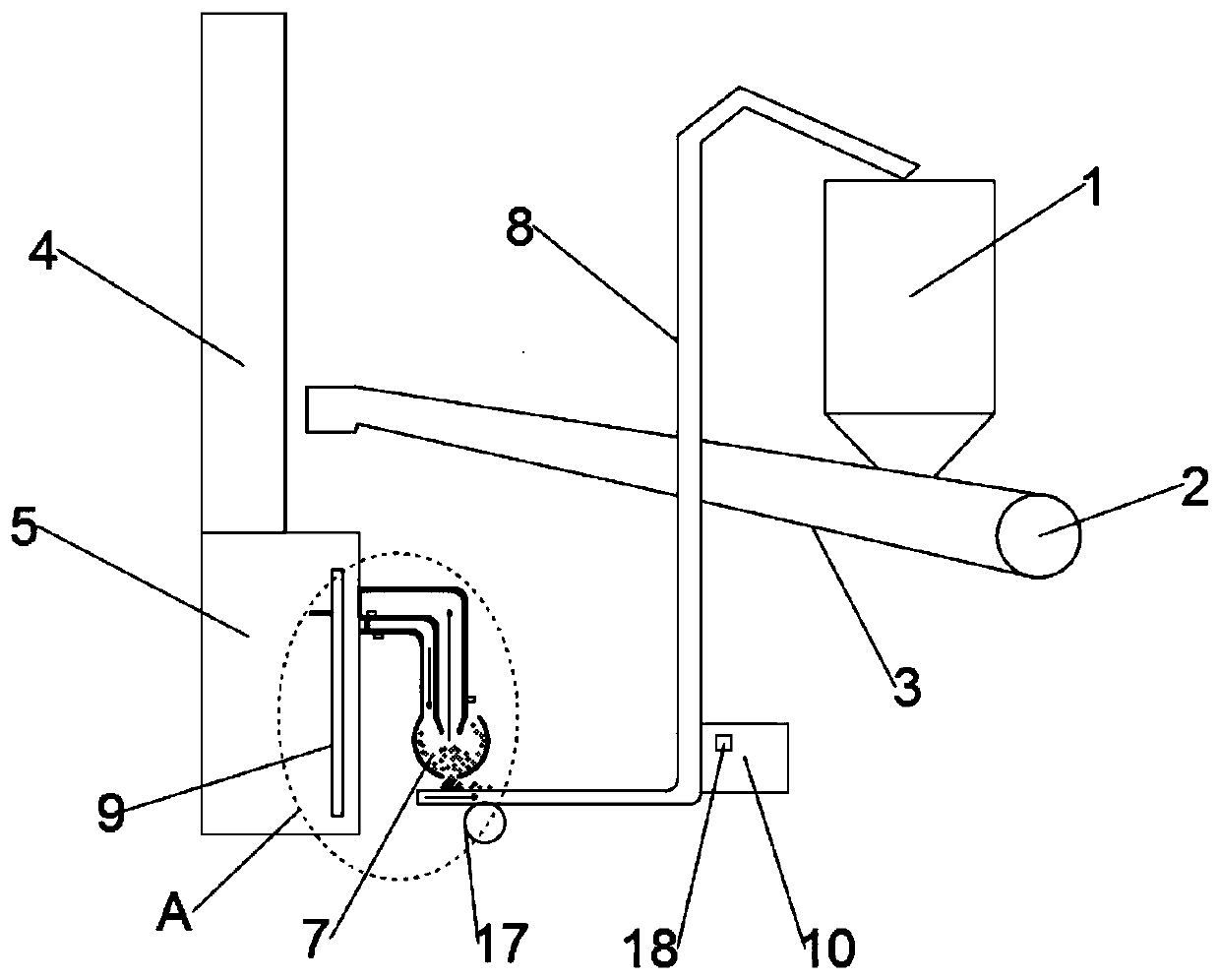

A control device, gypsum powder technology, applied in the conveyor control device, loading/unloading, transportation and packaging, etc., can solve the problem of low stability of feeding, to speed up the transportation cycle, avoid overload work, feeding and returning. The material process is stable and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

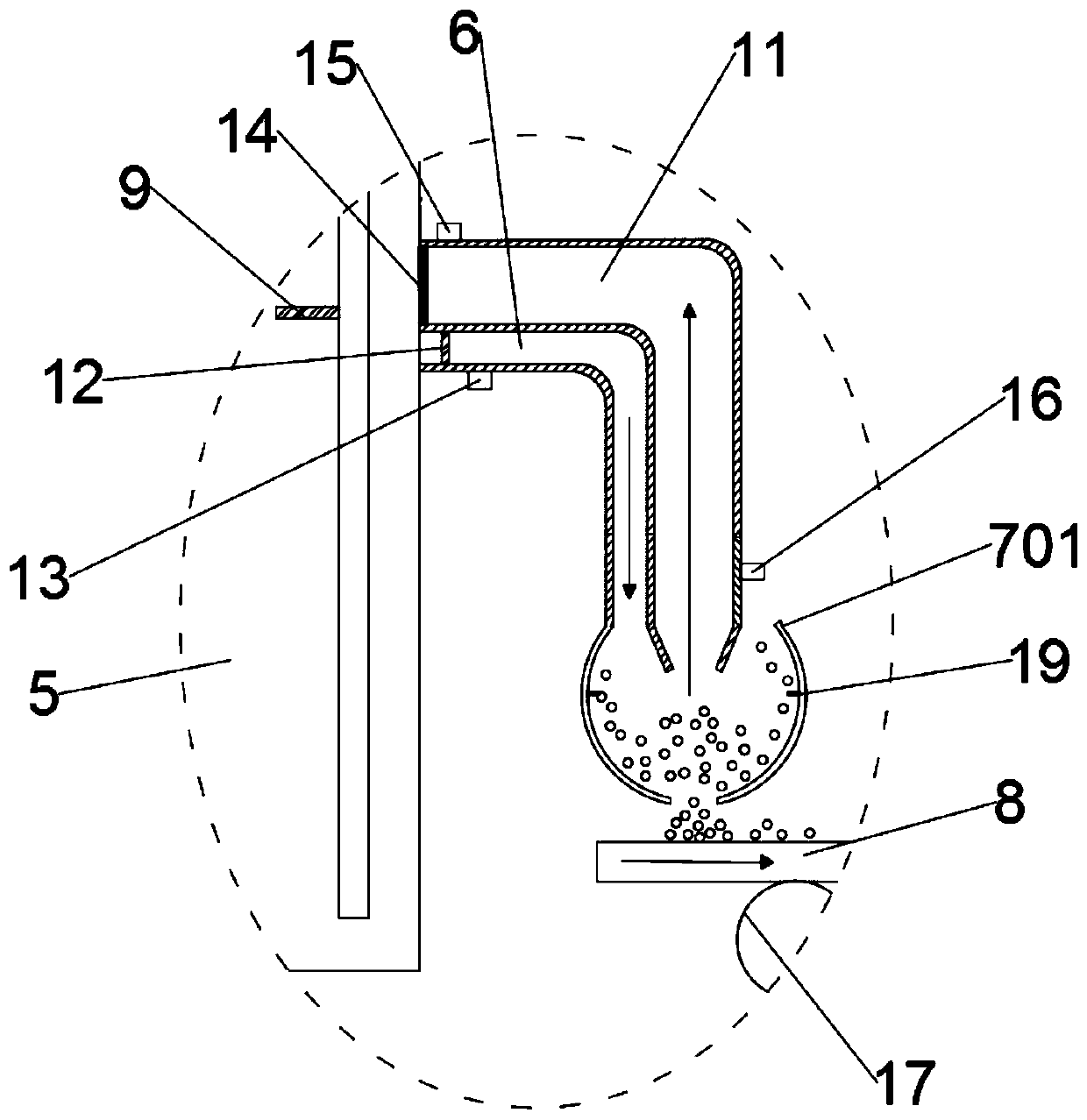

[0048] In order to describe the working modes of each control and monitoring equipment in more detail, a specific embodiment is now used as a representative to deepen the understanding of the content of the present invention, specifically:

[0049] The basic return pipe 6 is provided with a first valve 12 , and the first valve 12 controls the on-off of the basic return pipe 6 .

[0050] The basic return pipe 6 realizes the transportation of materials from the upper hopper lift 4 to the feed port 5 and back to the hopper 7 through the first power device 13 . The first power device 13 may be a dust extraction device for dust materials, or a dust blowing device, and is not limited thereto, and is intended to realize the circulation and transportation of materials in the basic return pipe 6 .

[0051] The additional return pipe 11 is provided with a second valve 14 , and the second valve 14 controls the on-off of the additional return pipe 11 .

[0052] The additional return pipe...

Embodiment 3

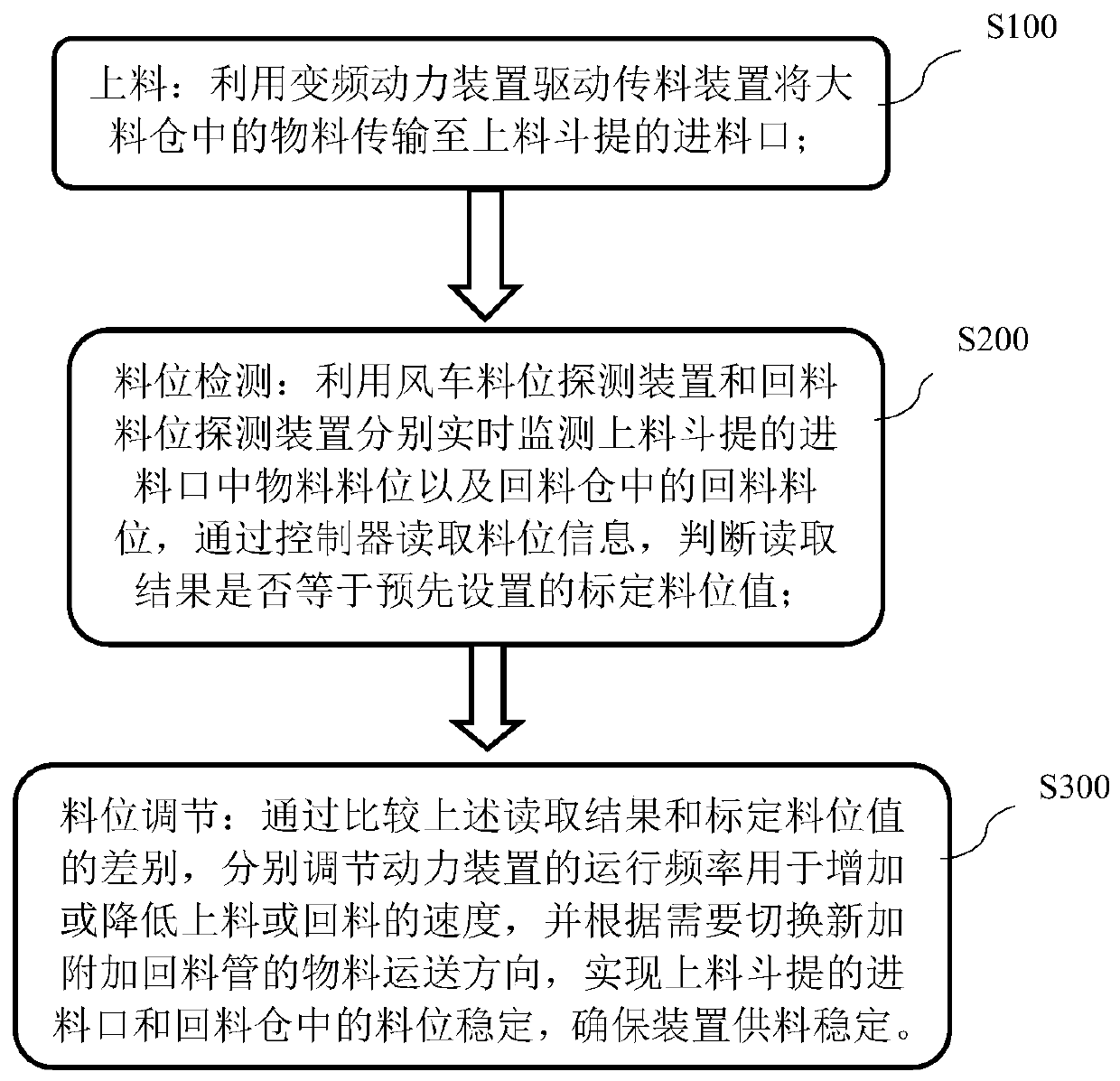

[0058] Such as image 3 Shown, a kind of control method of gypsum powder dry material feeding comprises the steps:

[0059] S100, feeding: use the frequency conversion power device to drive the material transfer device to transfer the material in the large silo to the material inlet of the upper hopper;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com