Slurry recovery system and method in electronic-grade polycrystalline silicon production

A recovery system, polysilicon technology, applied in separation methods, chemical instruments and methods, halogenated silanes, etc., can solve the problems of single filter residue treatment form, poor treatment effect, and high production cost, and achieve high heat transfer surface utilization. and thorough, exhaust-stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be further described below, and this embodiment does not constitute a limitation to the present invention.

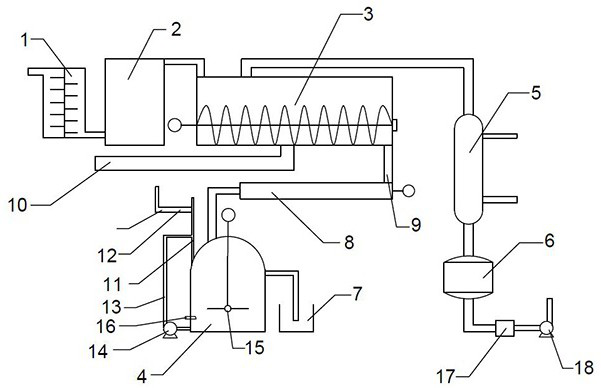

[0019] like figure 1 A slurry recovery system in the production of electronic grade polysilicon is shown, including a rotary filter 1, an overflow tank 2, a vacuum paddle dryer 3, a hydrolysis tank 4, a condenser 5, and a liquid storage tank 6, and the rotary filter 1 The inlet of the rotary filter 1 is connected to the bottom inlet of the overflow tank 2, the top outlet of the overflow tank 2 is connected to the inlet of the vacuum paddle dryer 3, and the bottom outlet of the vacuum paddle dryer 3 is connected to the hydrolysis tank 4 is connected at the top, the outlet of the upper end of the hydrolysis tank 4 is connected with the waste liquid pool 7, the exhaust port at the top of the vacuum paddle dryer 3 is connected with the condenser 5, and the liquid outlet of the condenser 5 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com