Water-permeable concrete synergist

A technology for strengthening agent and concrete, applied in the field of concrete additives, can solve the problems of high cost, complex preparation process, narrow application range, etc., and achieve the effects of enhancing mechanical strength, enhancing water permeability, and improving water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

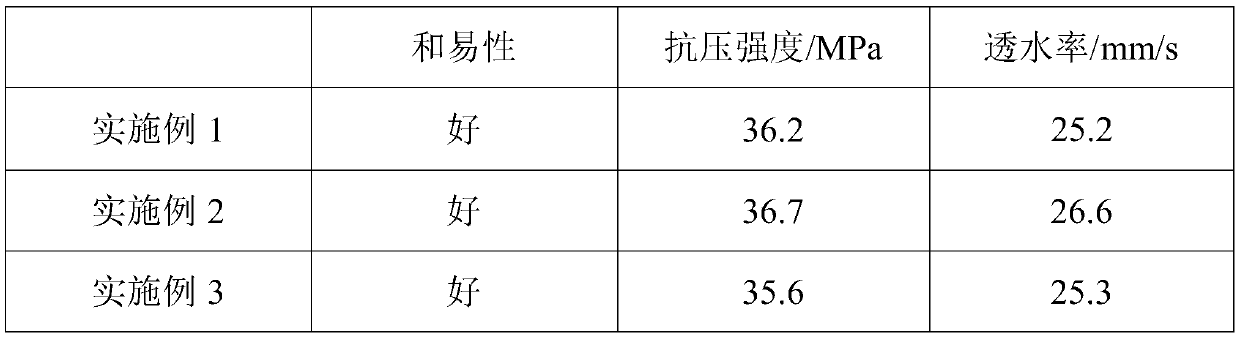

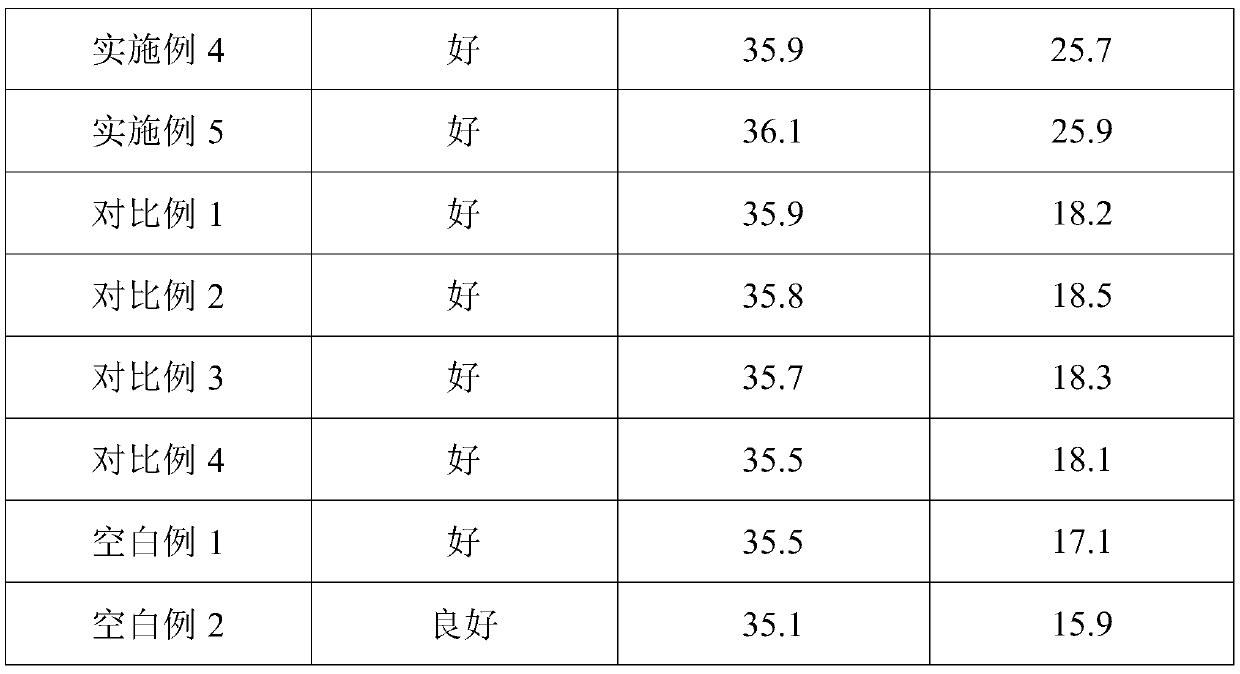

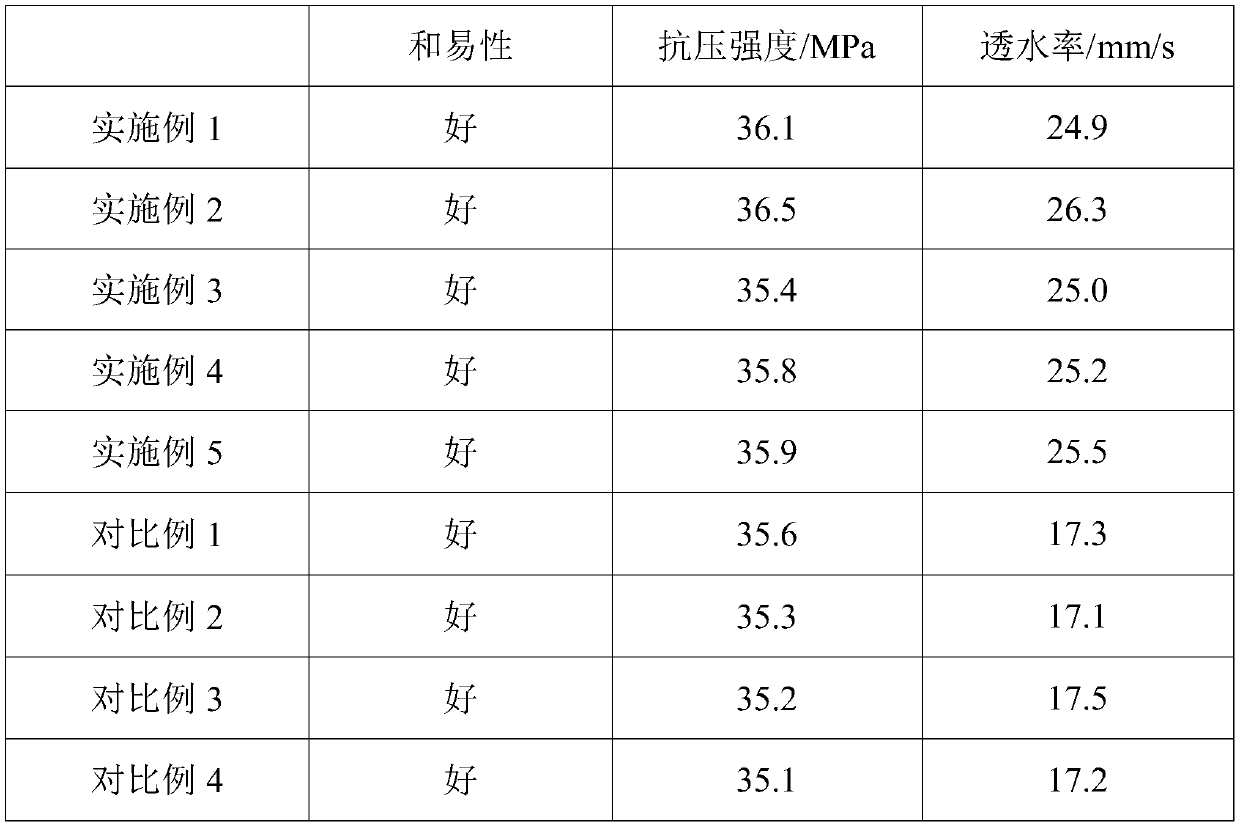

Examples

Embodiment 1

[0046] This embodiment provides a water-permeable concrete strength agent. The raw materials of the strength agent include: 10 parts of sodium lignosulfonate, 1 part of isopentenol polyoxyethylene ether TPEG-2400, water-reducing 5 parts of medicine, 30 parts of water.

[0047] The preparation method of the water reducing agent is:

[0048] Stir and mix 20 parts of sodium lignosulfonate, 40 parts of water and 15 parts of sodium dodecyl sulfonate at 200 rpm for 90 minutes, then add 12 parts of stearyl alcohol and continue stirring and mixing at 200 rpm for 90 minutes. Stand still for 180min, and cool to room temperature to obtain the water reducer.

Embodiment 2

[0050] This embodiment provides a water-permeable concrete strength agent. The raw materials of the strength agent include: 25 parts of sodium lignosulfonate, 5 parts of isopentenol polyoxyethylene ether TPEG-2400, water-reducing 10 parts of medicine, 50 parts of water.

[0051] The preparation method of the water reducing agent is:

[0052] Stir and mix 30 parts of sodium lignosulfonate, 60 parts of water and 20 parts of sodium dodecyl sulfonate at 500 rpm for 30 minutes, then add 20 parts of cetyl alcohol and continue to stir and mix at 500 rpm for 30 minutes. Stand still for 120min, and cool to room temperature to obtain the water reducer.

Embodiment 3

[0054] This embodiment provides a water-permeable concrete strengthening agent. The raw materials of the strengthening agent include: 20 parts of sodium lignosulfonate, 3 parts of isopentenol polyoxyethylene ether TPEG-2400, water-reducing 8 parts of medicine, 40 parts of water.

[0055] The preparation method of the water reducing agent is:

[0056] Stir and mix 22 parts of sodium lignosulfonate, 50 parts of water and 16 parts of sodium dodecyl sulfonate at 300 rpm for 60 minutes, then add 20 parts of dodecyl alcohol and continue stirring and mixing at 300 rpm for 60 minutes. Stand still for 150min, and cool to room temperature to obtain the water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com