Extraction method for lignin in moringa seed husks and application

An extraction method and technology of Moringa oleifera seeds, which are applied in the field of lignin extraction from Moringa oleifera seed husks, can solve problems such as insufficient utilization of moringa oleifera seed husks, and achieve the effects of facilitating characterization and analysis and improving purity

Inactive Publication Date: 2019-11-05

SOUTHWEST UNIVERSITY

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In view of the shortcomings of the prior art described above, the purpose of the present invention is to provide a method for extracting lignin

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

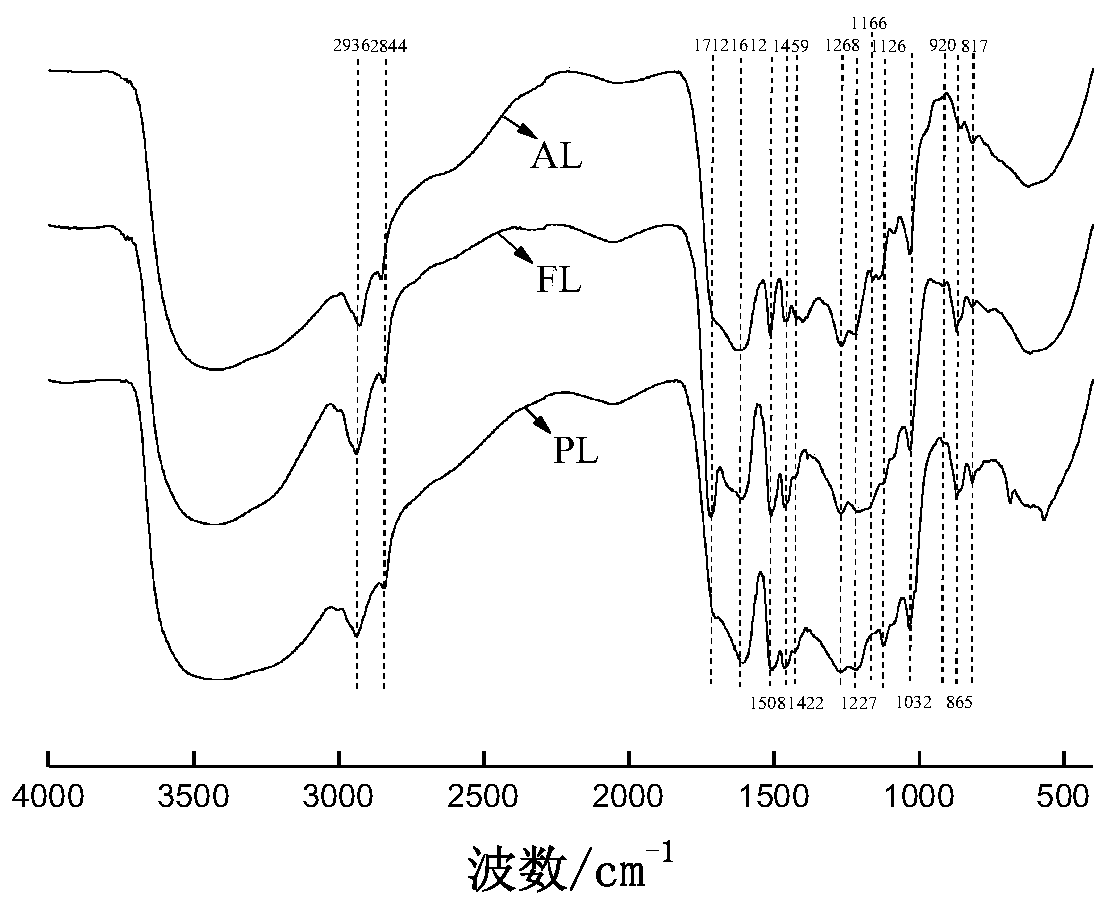

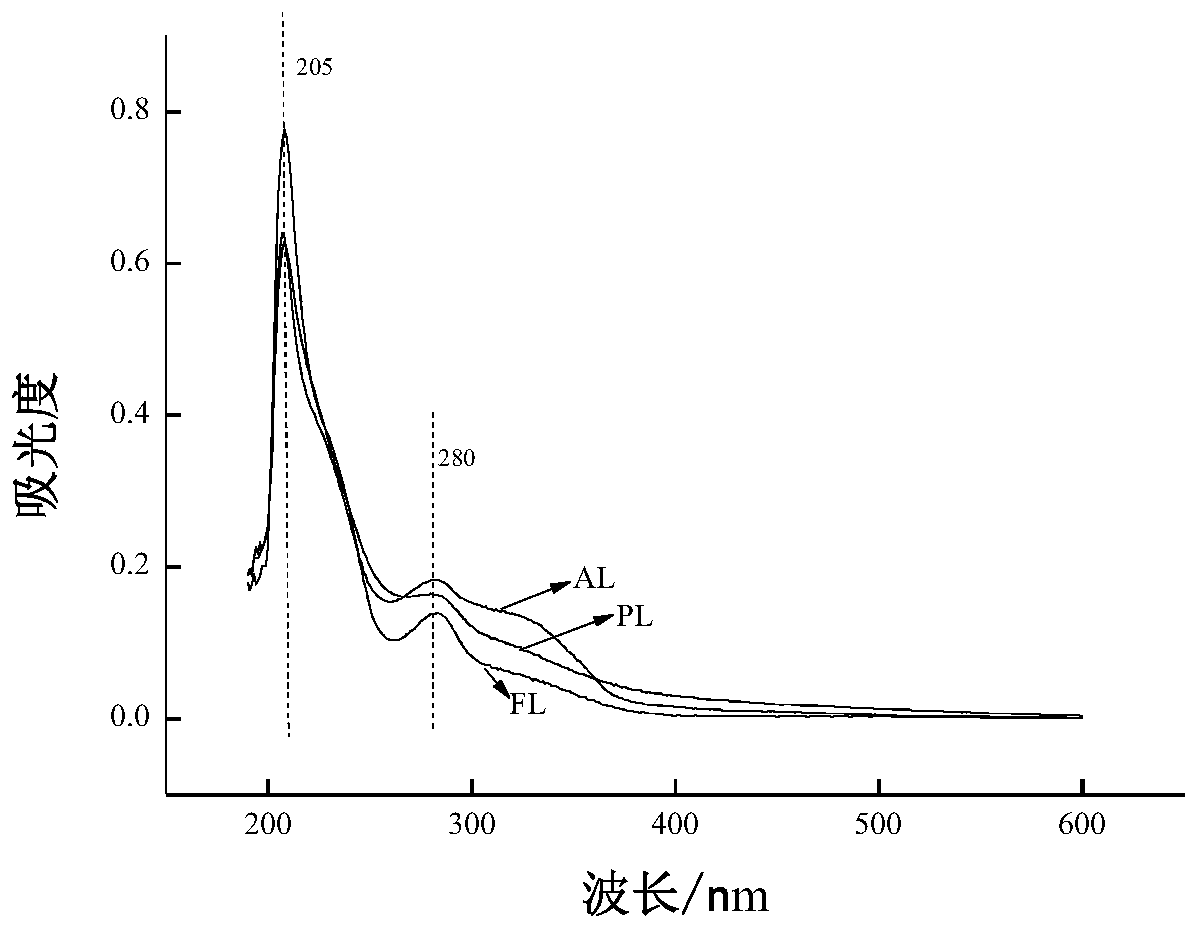

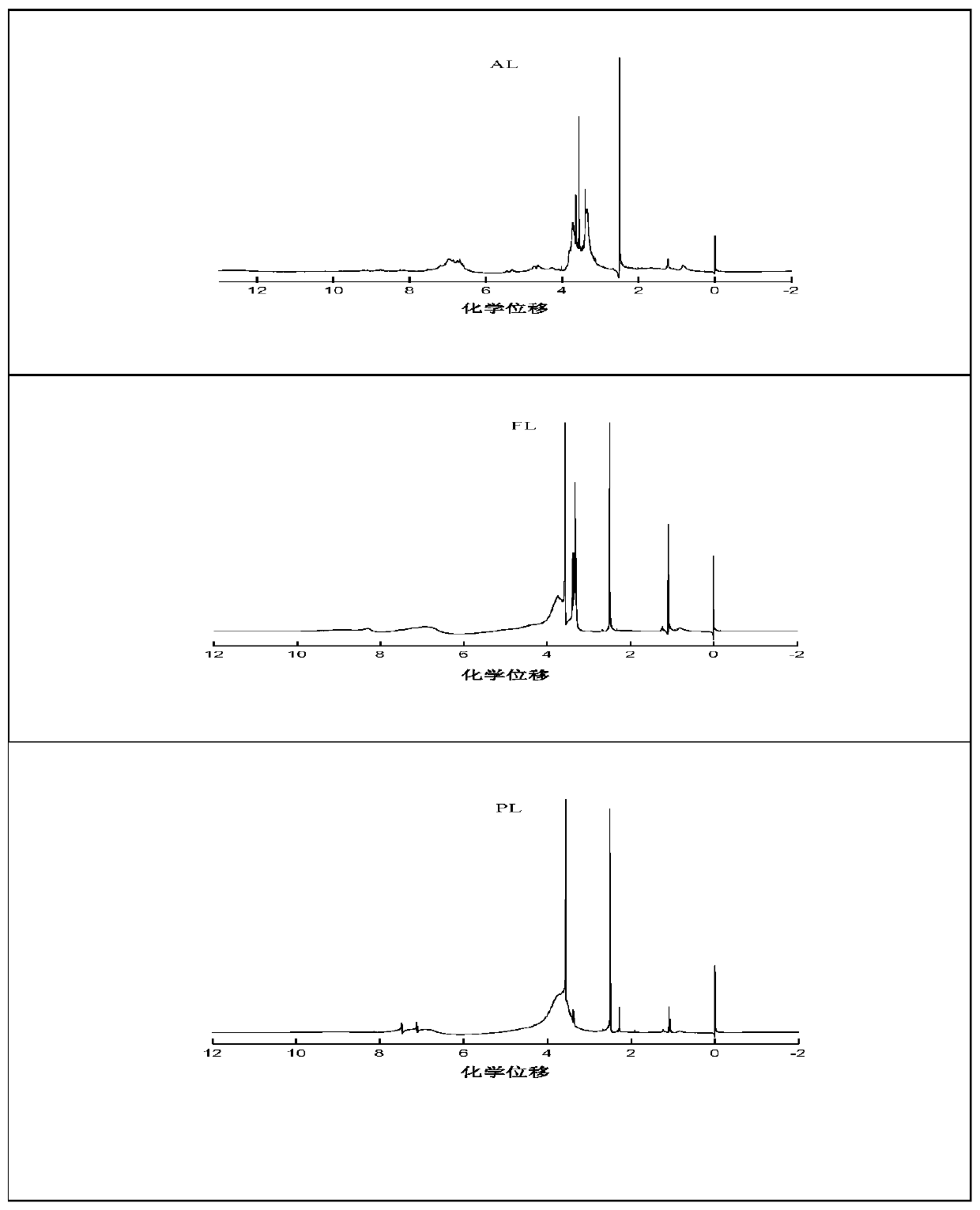

The invention relates to the technical field of lignin extraction and particularly provides an extraction method for lignin in moringa seed husks. The method comprises the steps that raw materials arepre-treated, an alkaline process or a formic acid process or a toluenesulfonic acid process is adopted for extracting the lignin in the moringa seed husks, the lignin is purified to remove impurities, after the structure of the lignin is represented, the moringa seed husk lignin products obtained through extraction in the three processes have similar chemical structures and properties and are GSHlignin, the lignin extracted through the three processes has high oxidation resistance, the oxidation resistance of the lignin is obviously higher than that of a commercial antioxidant BHT, the lignin can be used as a natural antioxidant, and the moringa seed husks are conveniently recycled.

Description

technical field [0001] The invention relates to the field of lignin extraction, in particular to a method for extracting lignin from Moringa oleifera seed shell and its application. Background technique [0002] Lignocellulosic biomass has been recognized for the production of chemicals and biomaterials. Lignin is the second most abundant natural polymer, comprising 10-25% of lignocellulosic biomass. Lignin is an aromatic polymer composed of three basic structural units of guaiacylphenylpropane (G), syringylphenylpropane (S) and p-hydroxyphenylphenylpropane (H). A large number of active groups such as methoxy, hydroxyl, and carboxyl can participate in a variety of chemical reactions, and are widely used in synthetic resins, hydrogels, stabilizers, and dispersants. [0003] There are a variety of lignin sources to choose from, such as jute, bamboo, cotton and wood pulp. The extraction methods of lignin mainly include inorganic solvent method and organic solvent method. Ino...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08H7/00A23L3/3472

CPCA23L3/3472A23V2002/00C08H6/00A23V2250/21

Inventor 钟金锋覃小丽李丰泉曾凡坤阚建全刘雄张甫生郑炯索化夷

Owner SOUTHWEST UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com