Needle bar presser foot device of computerized embroidery machine

A needle bar and coil embroidery technology, applied in the direction of embroidery machine, feeding device, embroidery machine mechanism, etc., can solve the problems of broken thread of light guide fiber, incomplete breakage, affecting light transmission, etc. The update of production machinery and the effect of smooth work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

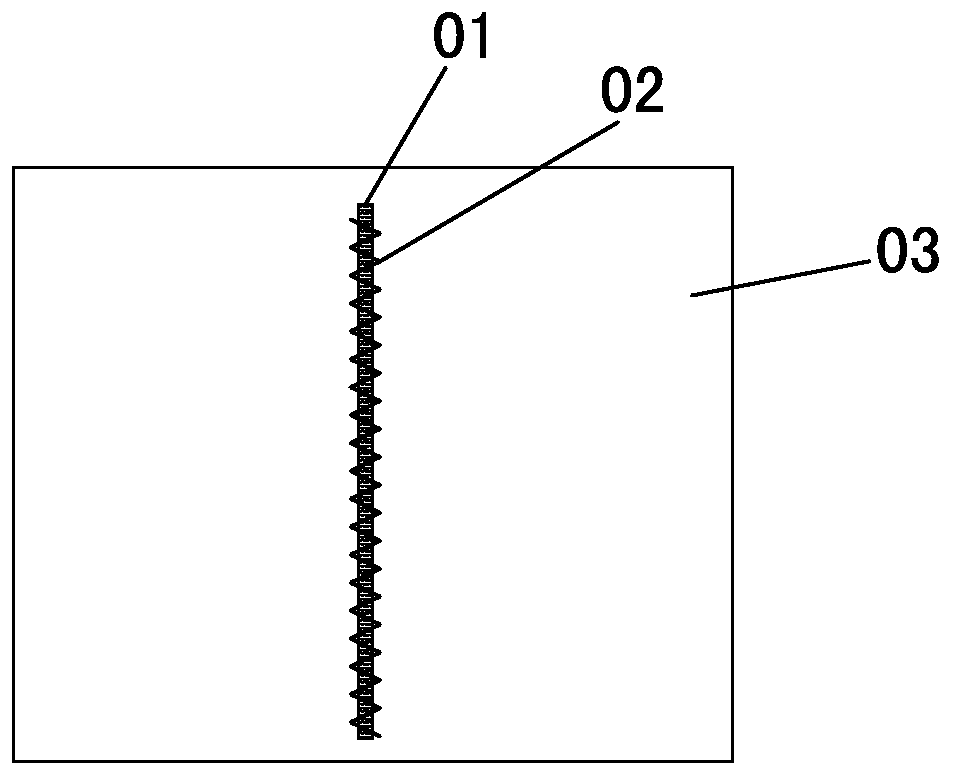

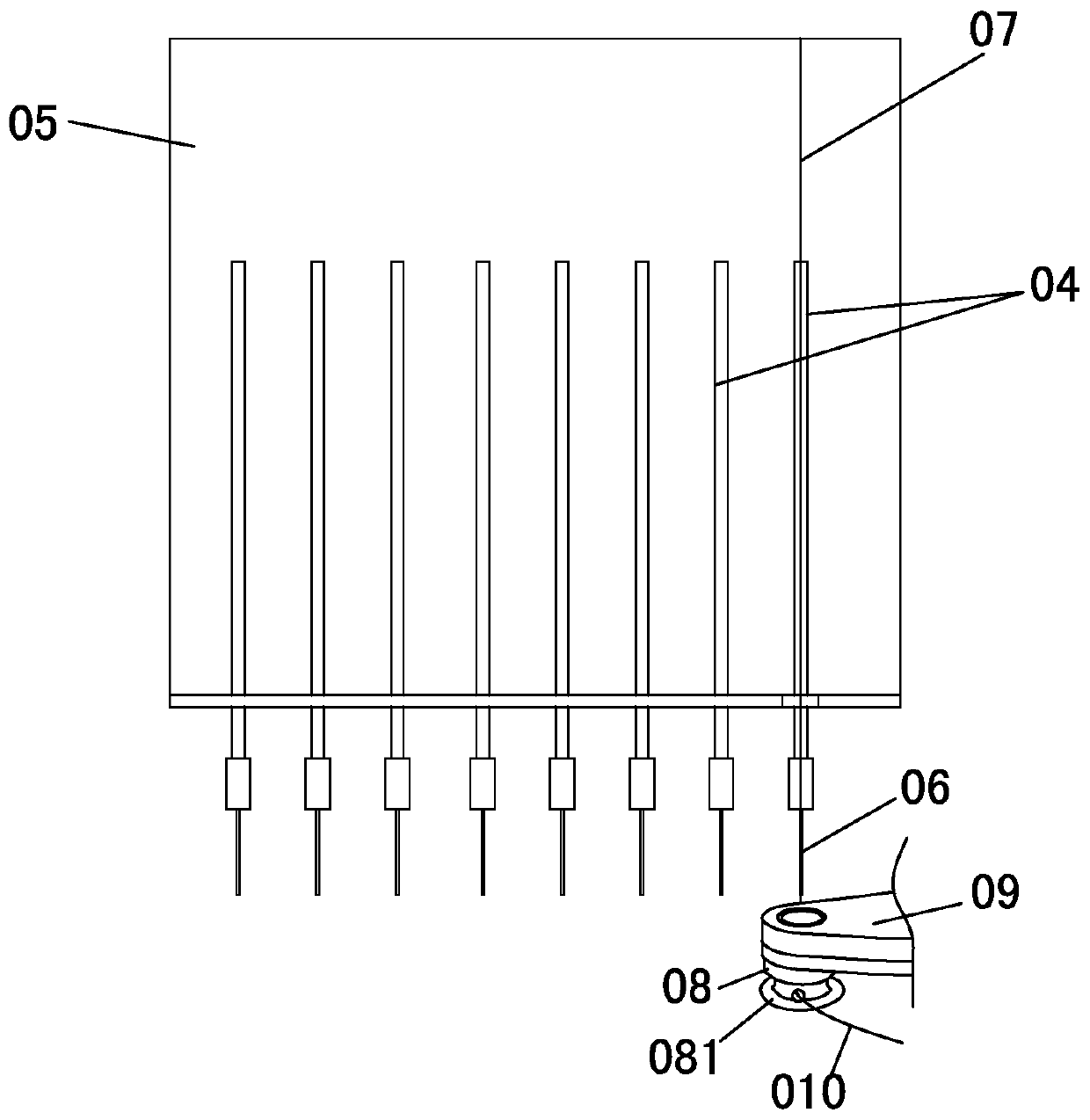

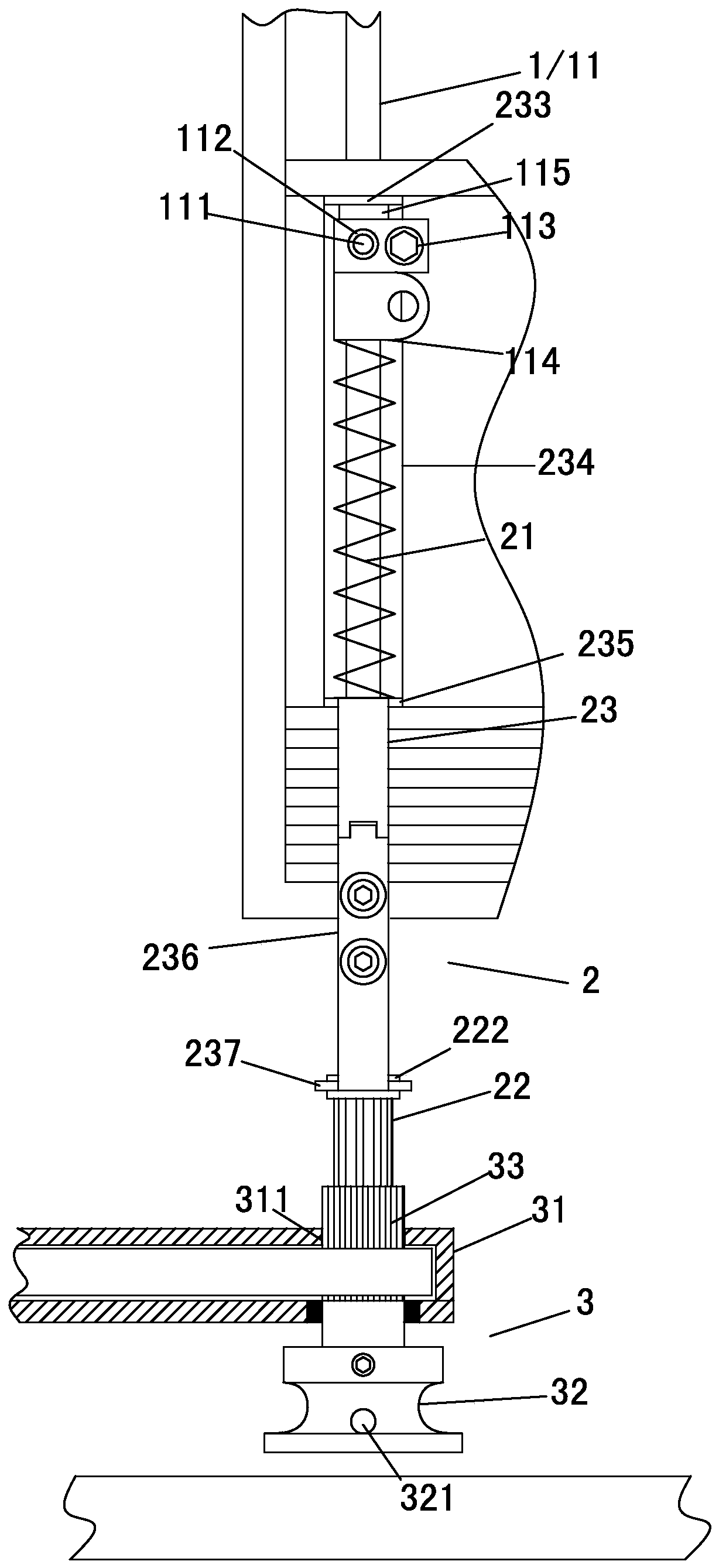

[0042] The present invention discloses a needle bar presser foot device for a computer coil embroidery machine, such as image 3 , Figure 4 , Figure 5 and Figure 6As shown, it includes a needle bar mechanism 1, a presser foot mechanism 2 and a coiling rope mechanism 3. The needle bar mechanism 1 is used for the installation and setting of the coil embroidery upper thread needle and the realization of lifting activities, and the coiled rope structure 3 is used for realizing automatic Turning to the coil rope, the presser foot mechanism 2 is used to press the fabric with the lifting movement of the needle bar. The program trace of the pattern-making software programming of design controls work, and the main difference of the present invention and prior art points out in the setting with presser foot mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com