Grouting device

A grouting device and grouting technology, which are used in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of difficult to stably ensure the sealing quality, limited construction site space, inconvenient moving machinery and equipment, etc. Easy to connect, easy to clean and maintain, easy to separate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the reference numerals refer to components and techniques in the present invention, so that the advantages and features of the present invention can be more easily understood in a suitable environment. The following description is the embodiment of the claims of the present invention, and other specific implementations related to the claims that are not explicitly described also belong to the scope of the claims.

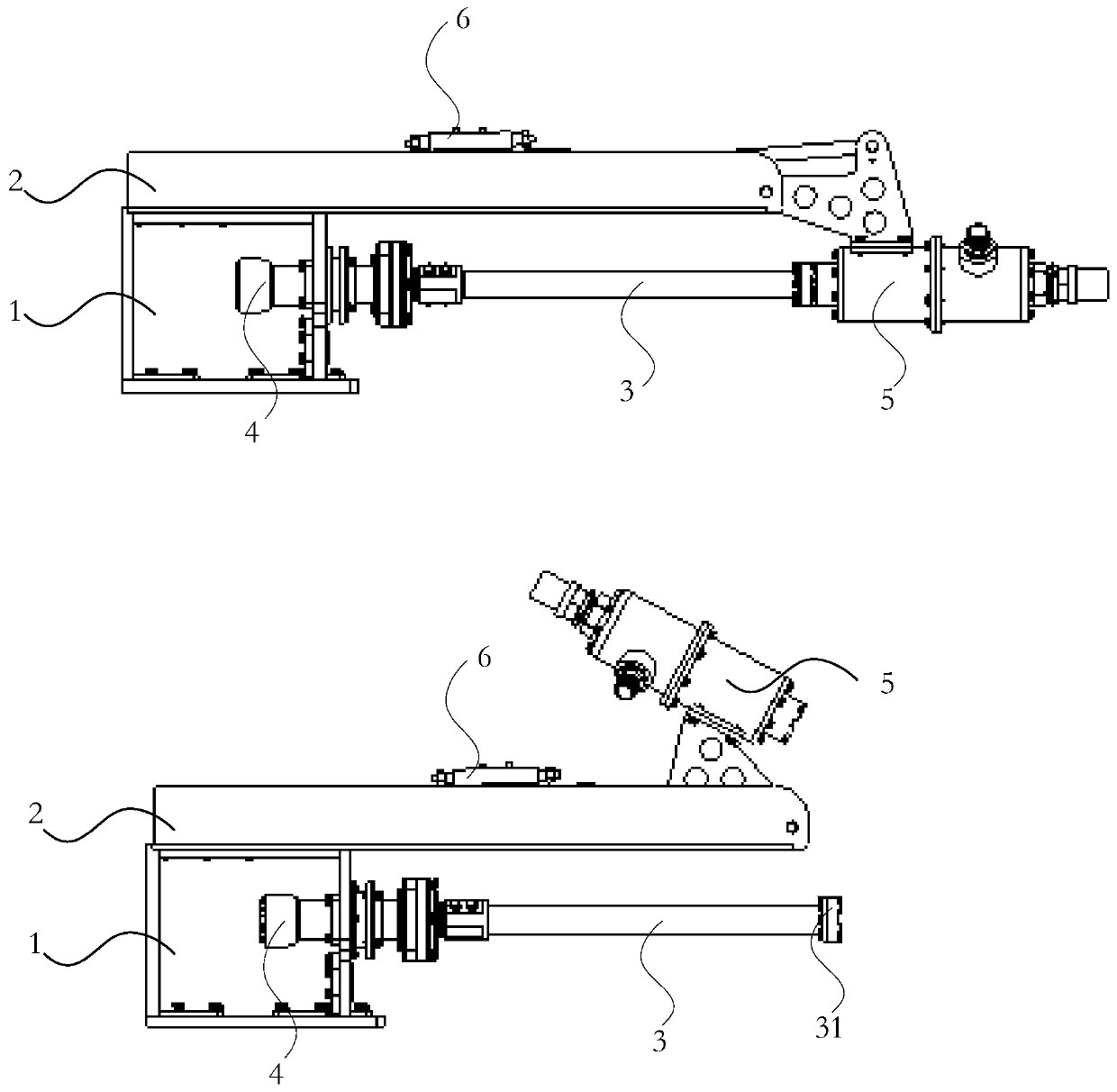

[0024] figure 1 The structure of the grouting device of the present invention is shown.

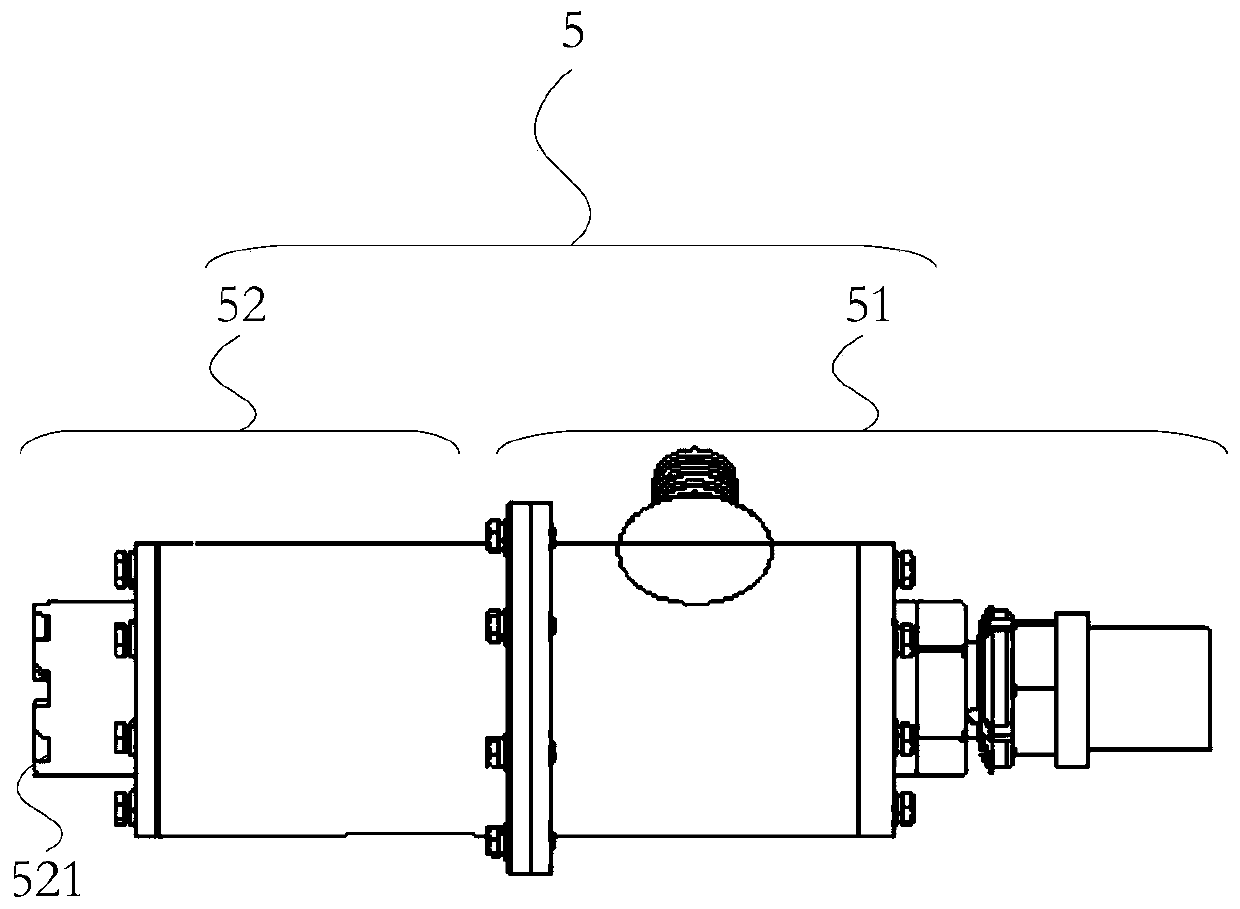

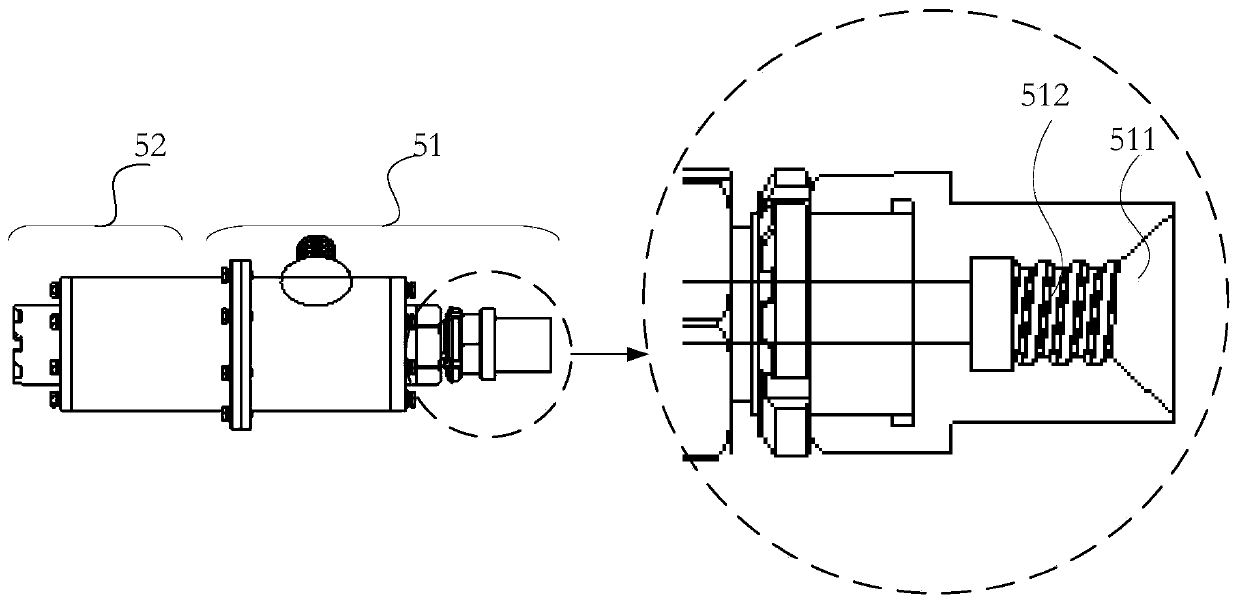

[0025] like figure 1 As shown, the grouting device includes a bottom bracket 1, an upper bracket 2, a docking rod 3, a docking rod driving device 4, a grouting conversion head 5, and a grouting conversion head driving device 6. The bottom bracket 1 is used for installing the docking rod 3 and the docking rod driving device 4 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com