Nozzle sheet, combustor and gas water heater

A burner and fire-discharge fin technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of turbulent secondary air flow, high noise, and high control technical requirements, and achieve uniform and stable secondary air. The effect of CO generation and combustion quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

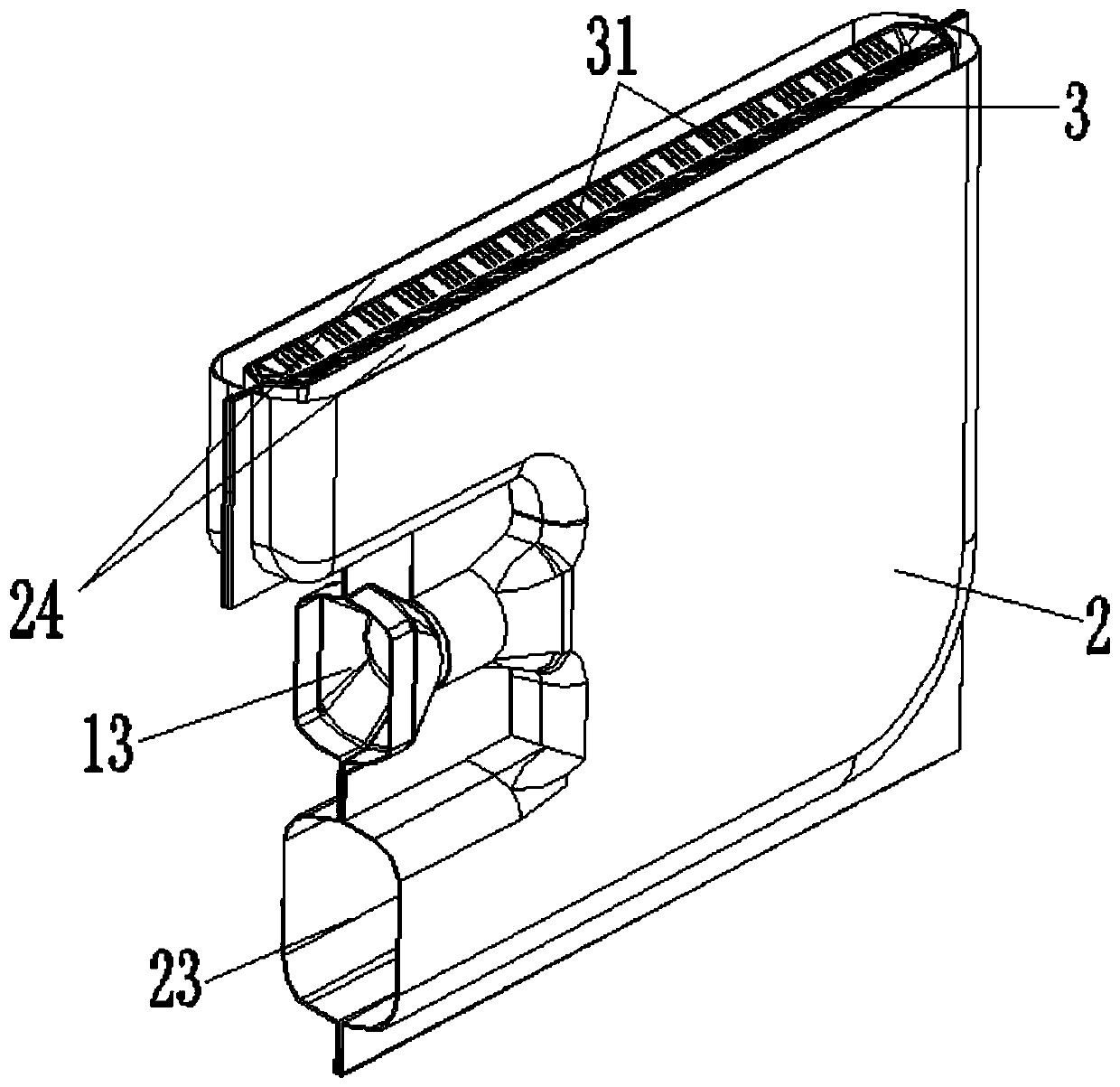

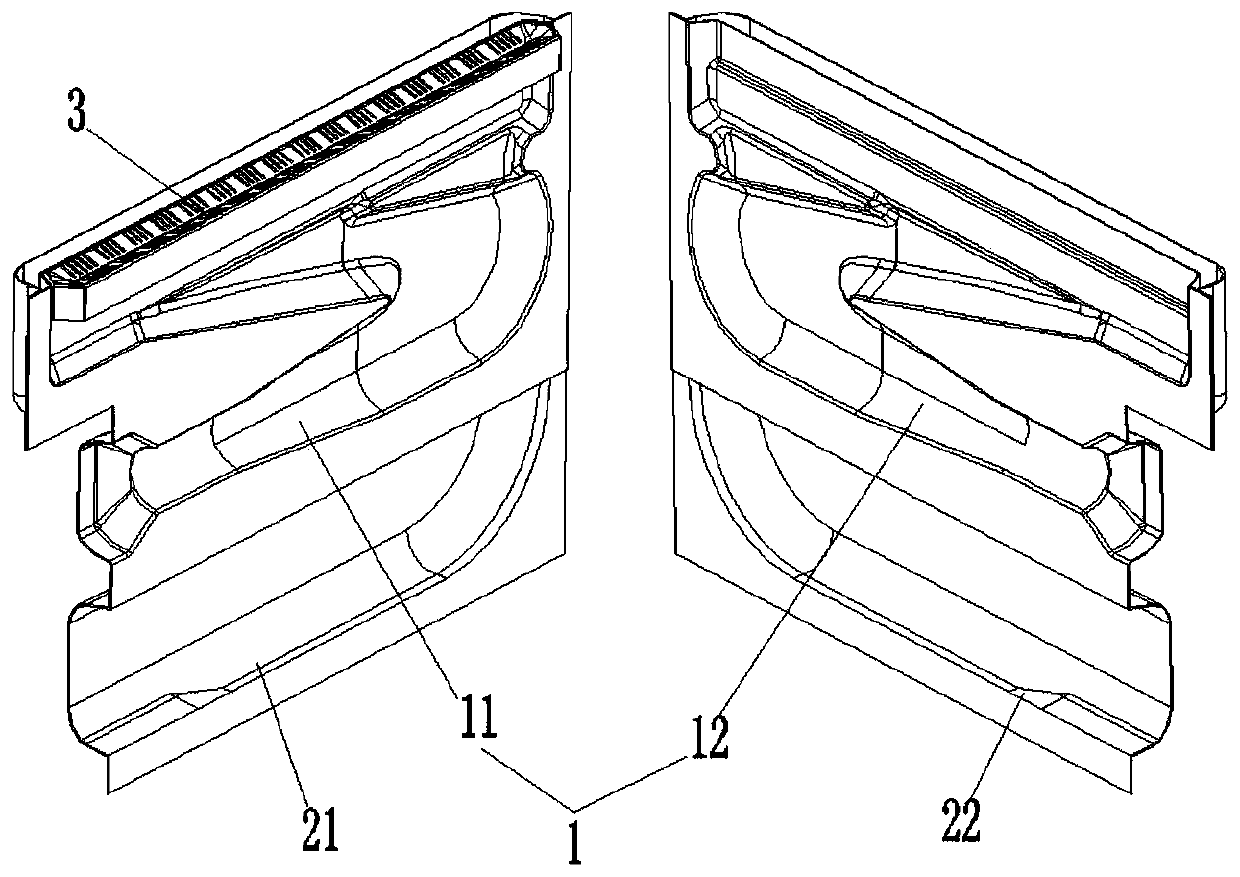

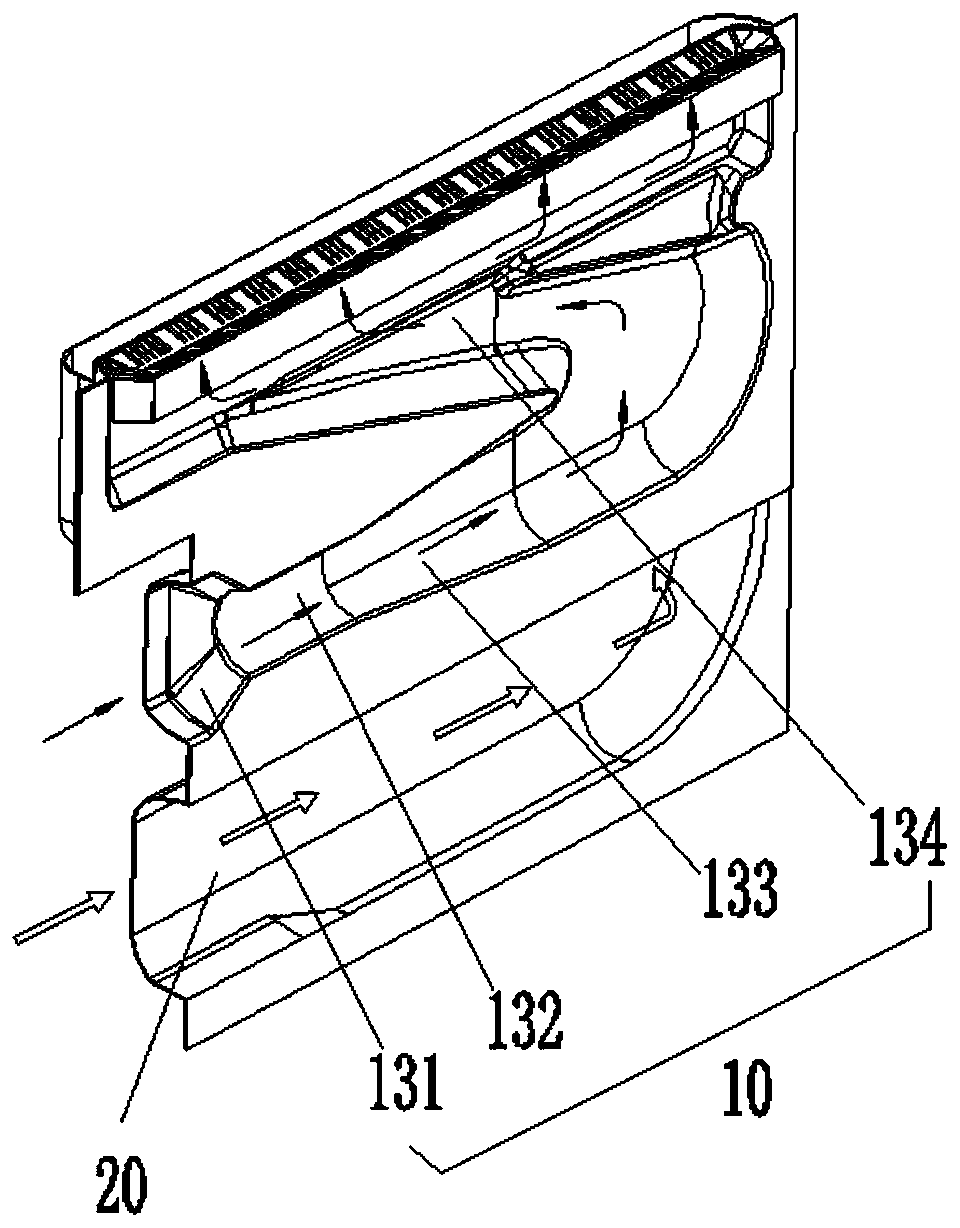

[0021] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present invention, a fire exhaust plate is provided, which includes a mixed gas flow channel housing 1 and a fire exhaust outer shell 2, and a mixed gas flow channel 10 is formed inside the mixed gas flow channel housing 1, so that The mixed gas flow channel 10 has a first outlet 14, and the first outlet 14 is covered with a fire row cover 3. It can be understood that a plurality of flame holes 31 are configured on the fire row cover 3, and the gas will eventually be discharged at The flame hole 31 burns, the mixed gas flow channel casing 1 is in the fire row outer casing 2, and there is a secondary The air channel 20 , the secondary air channel 20 has a second outlet 24 , and the second outlet 24 surrounds the fire cover 3 . In this technical solution, the secondary air channel 20 is constructed in the fire row sheet, so as to ensure that the second outlet 24 can surround the fire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com