Energy-saving control method for chilled water in air-conditioning system

An energy-saving control and air-conditioning system technology, which is applied in the direction of control input involving air characteristics, space heating and ventilation control input, heating and ventilation control system, etc., can solve energy waste, complex control logic, and increased work of the rear humidification system Load and other problems, to achieve the effect of reducing the humidification load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

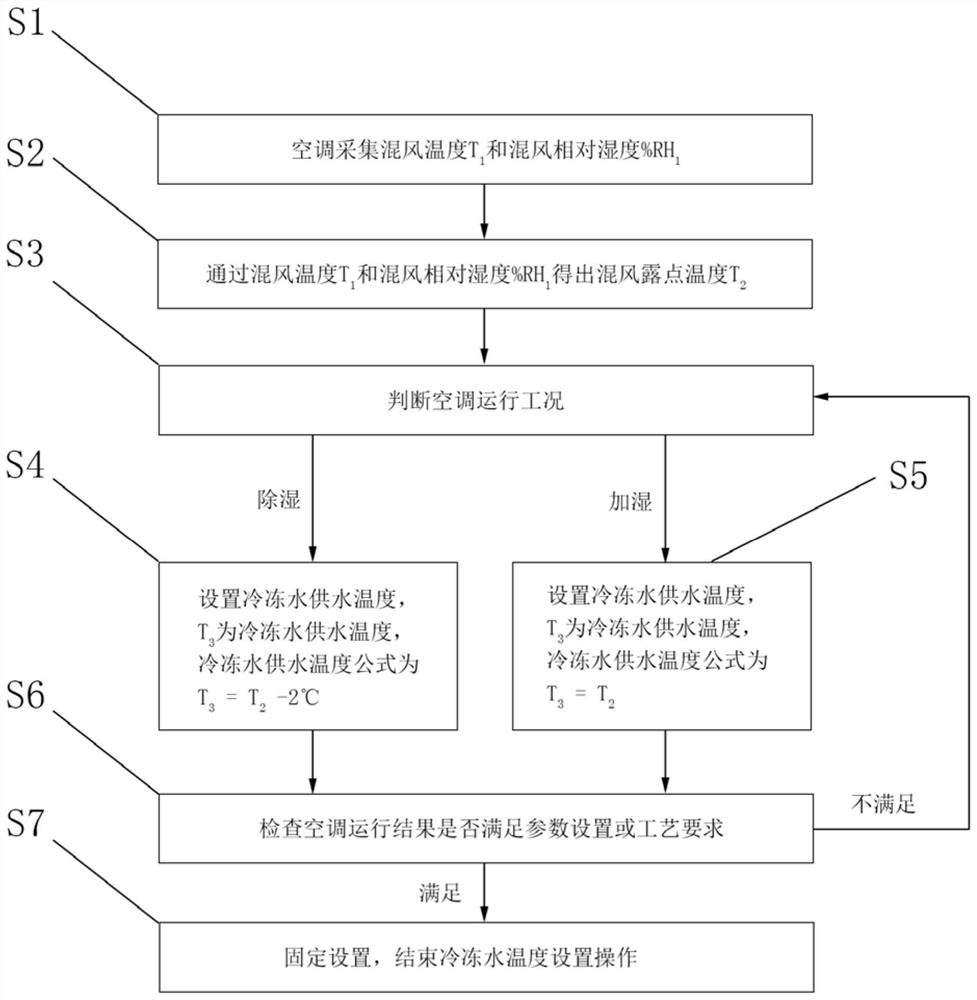

[0045] The present invention mainly adjusts correspondingly according to the different weights of chilled water used in different working conditions. like figure 1Shown is a flow chart of the energy-saving control method for chilled water in the air-conditioning system in the present invention. Embodiment 1 of the present invention provides an energy-saving control method for chilled water in an air-conditioning system, which includes the following steps:

[0046] Step S1, the air conditioner collects the mixed air temperature T 1 and mixed air relative humidity %RH 1 ;

[0047] Step S2, through the mixed air temperature T 1 and mixed air relative humidity %RH 1 Get the mixed air dew point temperature T 2 ;

[0048] Step S3, judging the operating condition of the air conditioner, if the operating condition is a dehumidification condition, proceed to step S4; if the operating condition is a humidification condition, then proceed to step S5;

[0049] Step S4, set the chi...

Embodiment 2

[0064] The difference between this embodiment and Embodiment 1 is that this embodiment provides an energy-saving control method for chilled water in an air-conditioning system, and the steps S1 and S2 in Embodiment 1 are replaced by the following steps:

[0065] Step S31, using a dew point meter to measure the dew point temperature T of the mixed air 2 .

[0066] The dew point meter is a mirror type dew point meter or an electrolytic dew point meter or a crystal oscillator type dew point meter or an infrared dew point meter or an electric sensor type dew point.

[0067] The mirror dew point meter is made according to the characteristics that gases with different moisture contents will condense on the mirror surface at different temperatures. In addition, photoelectric detection technology is used to detect the dew layer and measure the temperature at the time of dew condensation, and directly display the dew point. Mirror refrigeration methods include: semiconductor refriger...

Embodiment 3

[0074] The difference between this embodiment and Embodiment 1 is that this embodiment provides an energy-saving control method for chilled water in an air-conditioning system, which includes a dry-wet bulb thermometer and a barometer, and the dry-wet bulb thermometer is used to measure the dry-bulb temperature and the wet-bulb temperature . A barometer is used to measure air pressure. This embodiment provides an energy-saving control method for chilled water in an air-conditioning system, which further includes the following steps instead of steps S1 and S2 in Embodiment 1:

[0075] Step S51, measuring the dry bulb temperature t and the wet bulb temperature t by using a wet and dry bulb thermometer w , using a barometer to measure the air pressure P h ;

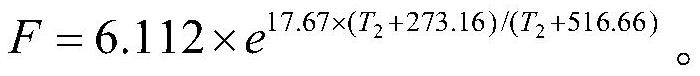

[0076] Step S52, through the dry and wet bulb temperature difference and the air pressure P h To calculate the water vapor pressure F in the air, the calculation formula is:

[0077] F=E tw -AP(t-t w );

[0078] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com