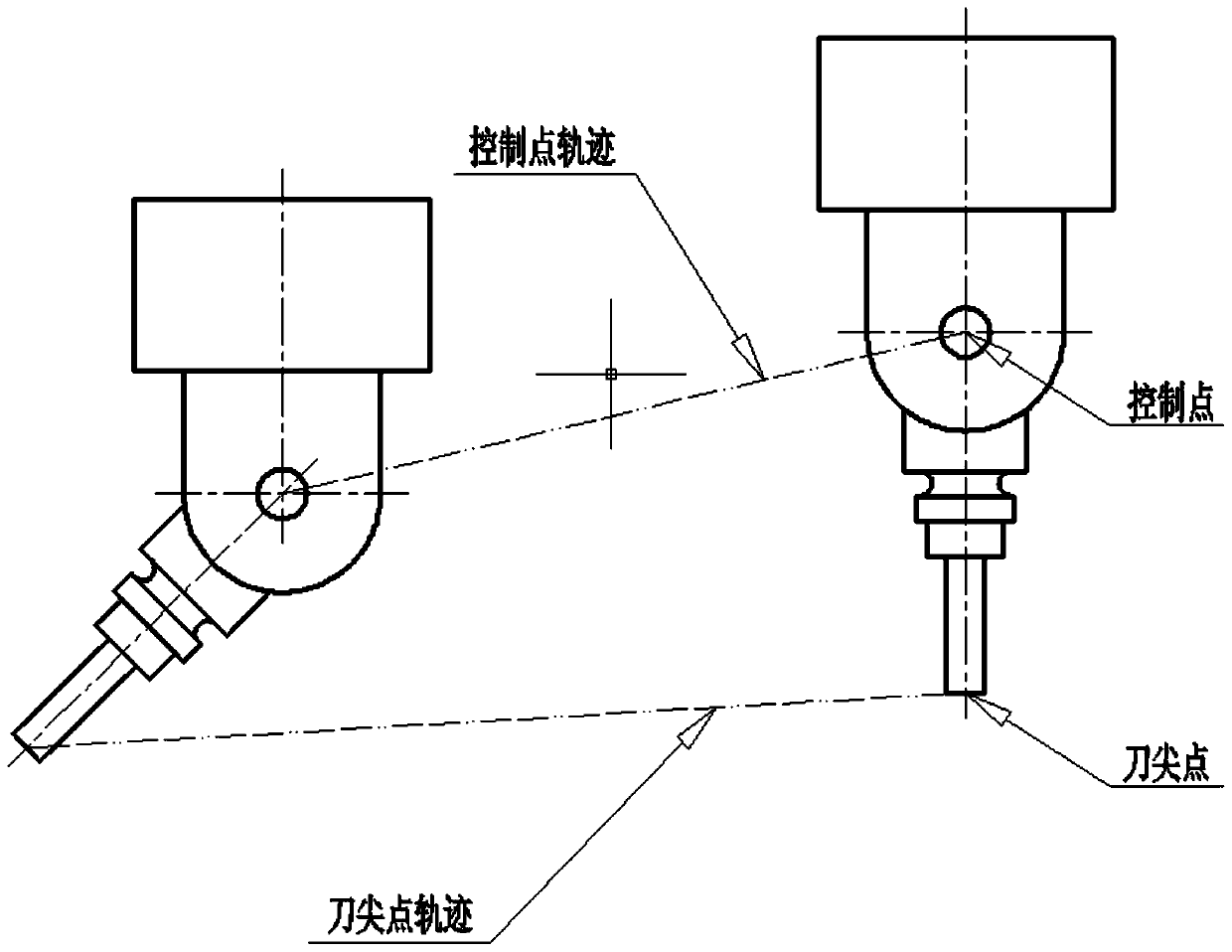

Method for achieving rotated tool center point function in four-shaft horizontal processing center by macroprogram

A machining center and macro program technology, applied in the direction of program control, electrical program control, general control system, etc., can solve the problems of reducing the versatility of NC programs, errors in processing results, and increasing the difficulty of clamping and alignment, and achieve alignment Convenience, cost reduction, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

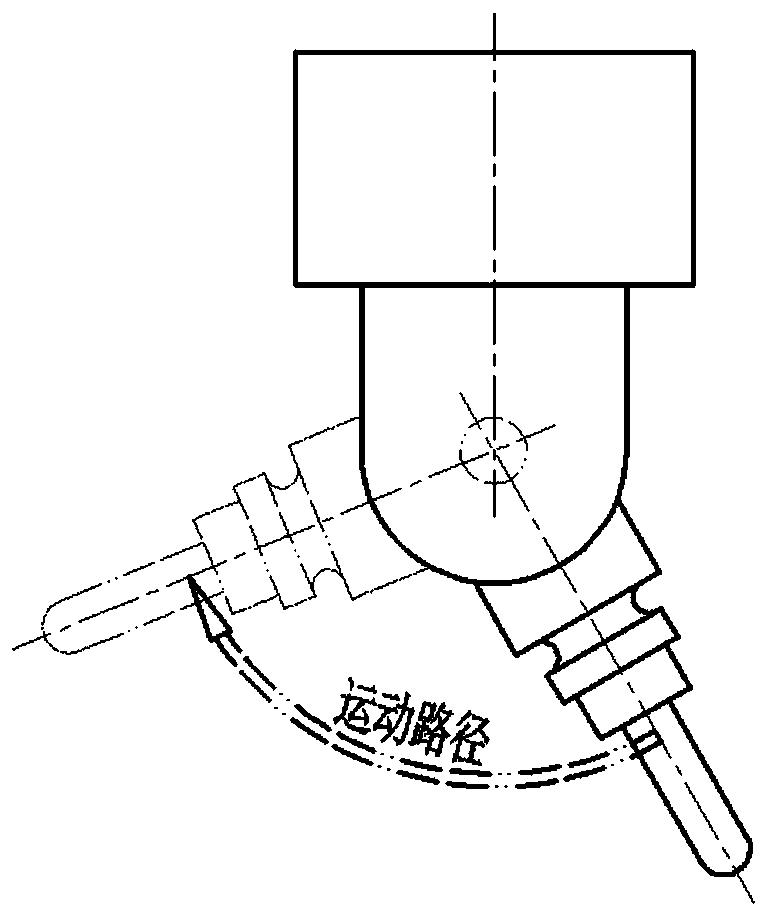

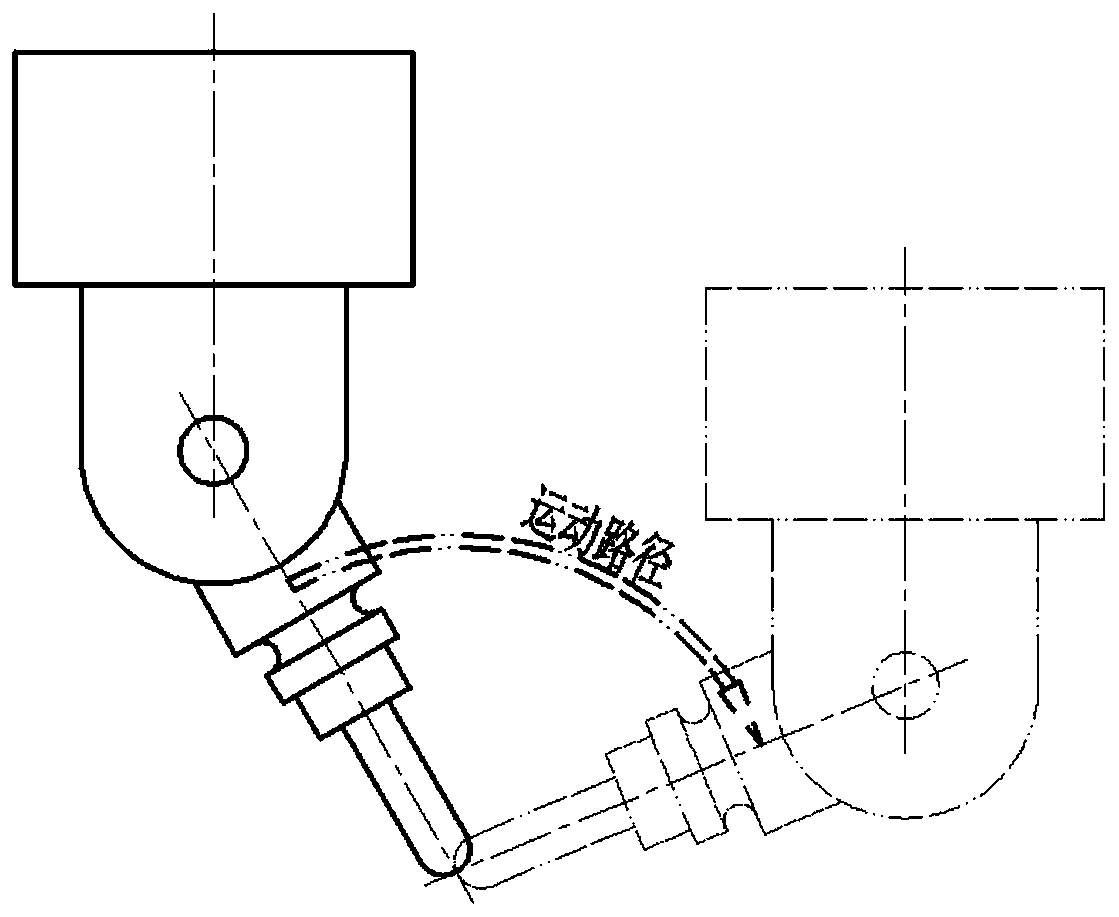

Method used

Image

Examples

Embodiment

[0039] Measure the X coordinate and Z coordinate (relative to the reference point of the tool length) of the machine tool table rotation center in the mechanical coordinate system (MCS), and write it into the macro program as a constant. The measurement results here are 111.111 and 333.333;

[0040] Write the above-mentioned "G54→G57" part of the coordinate system transformation command into macro program 1, write the "G57→sub-coordinate" part of the coordinate system transformation command into macro program 2, and then store it in the "NC"→"subroutine" directory of the machine tool Next, the main instructions of the two macro programs (replace $AA_IW[B] in 4) with R11) are shown in Table 1 and Table 2;

[0041] Table 1

[0042]

[0043] Table 2

[0044]

[0045]Select any position of the machine tool workbench to clamp the workpiece. In order to verify the tool tip following (RTCP) function, deliberately stagger the center of rotation of the machine tool workbench, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com