Design method for improving heat generation and heat dissipation capacity of each encapsulated coil of reactor

A design method and technology of heat dissipation capability, applied in the fields of instrumentation, calculation, electrical and digital data processing, etc., can solve the problems of uneven distribution of temperature rise in the package, limit practical application, accuracy verification, etc., to improve the utilization rate of metal conductors, The temperature rise distribution is basically the same, and the effect of optimizing the heat load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

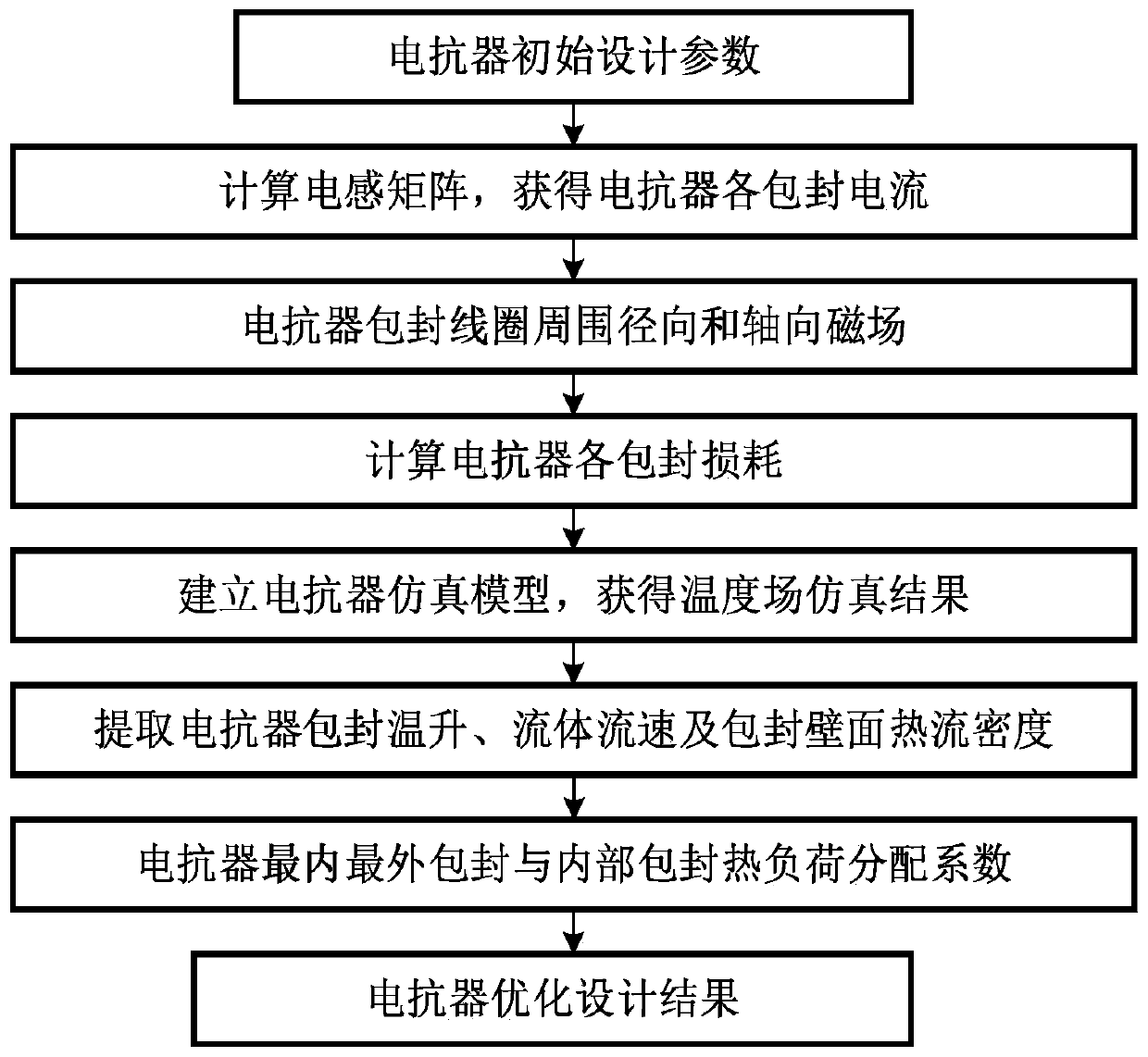

[0023] A design method for improving the heat generation and heat dissipation capacity of each enclosing coil of a reactor, comprising the following steps:

[0024] Step 1: Obtain the initial design parameters of the reactor, where the initial parameters of the reactor need to ensure that the internal packages have the same heat generation and heat dissipation capabilities, so that the internal packages of the reactor have the same temperature rise distribution and improve the internal package. conductor utilization. On this basis, according to the initial design parameters of the reactor, the mutual inductance matrix of the reactor is calculated, and combined with the total current flowing through the reactor, the current of each enclosing coil is obtained.

[0025] Step 2: According to the current of each enveloped coil of the reactor, the magnetic field distribution around the enveloped coil is calculated by analytical method, and then the loss of each coil in the envelope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com