Electric built-in shutter control hub

A hub and louver technology, applied in the field of electric built-in louver control hub, can solve the problems of affecting the appearance, reducing production efficiency, breaking the skin and short circuit of the motor line and the stroke control line, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

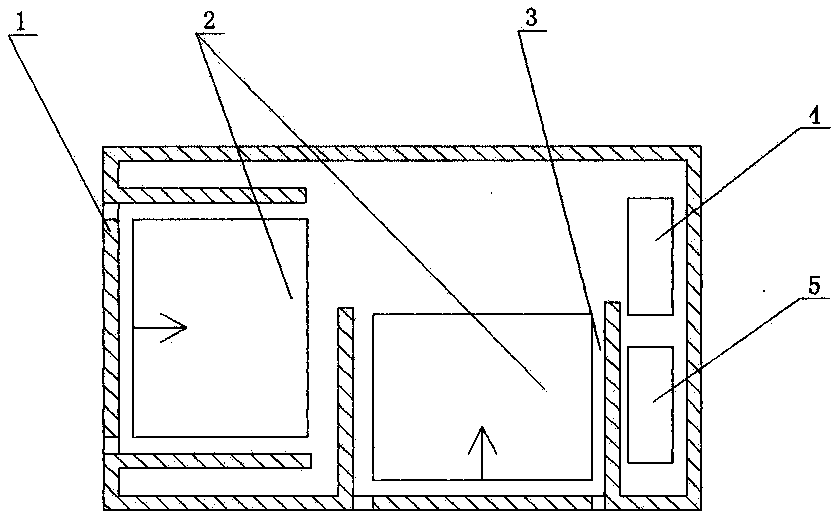

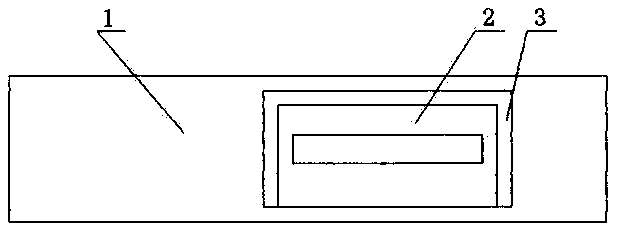

[0009] Combine below figure 1 and figure 2 The present invention will be further described in detail with specific embodiments.

[0010] In the figure, the electric built-in louver control hub is composed of hub box body 1, Type-c socket 2, guide groove 3, motor wire socket 4 and stroke control wire socket 5. The hub box body 1 is installed outside the electric built-in louver, and Type-c socket 2, guide groove 3, motor line socket 4 and stroke control line socket 5 are installed in it; Type-c socket 2 is a kind of quick socket, mainly It is used to connect with the electric built-in louver controller. The present invention adopts two Type-c sockets 2, which can realize the connection with the electric built-in louver controller in the vertical direction and the horizontal direction; the guide groove 3 is a part of the guide device. The main purpose is to make the electric built-in louver controller quickly connect with the Type-c socket 2 to play a guiding role; the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com