Seedling cultivation rack convenient to adjust planting height

A seedling rack and height technology, applied in the agricultural field, can solve the problems that the seedling rack cannot be adjusted, and the nutrient solution is prone to precipitation, etc., and achieve the effect of expanding the spraying range and mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

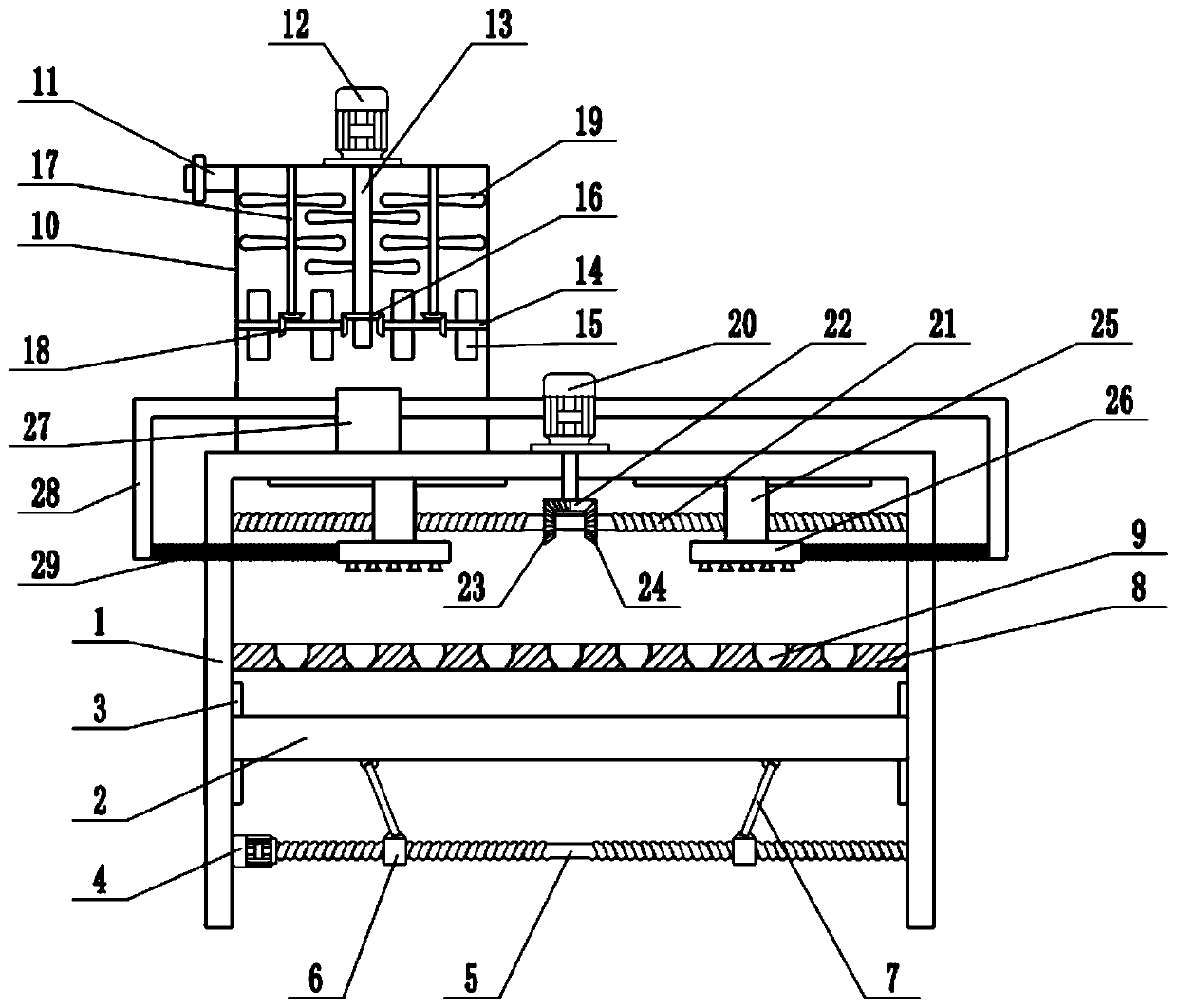

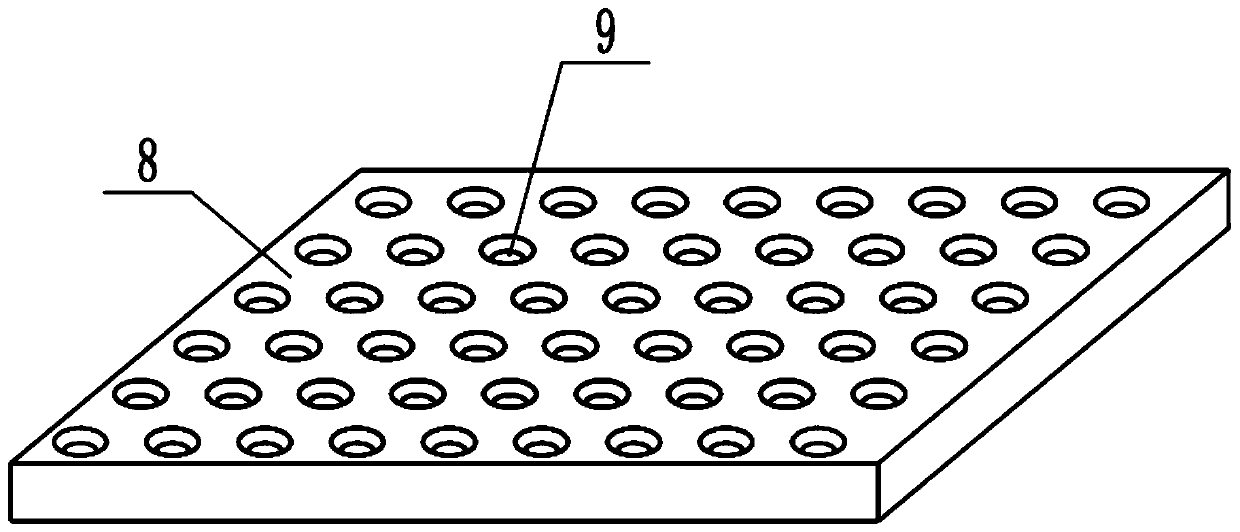

[0020] see Figure 1-3 , in the embodiment of the present invention, a kind of seedling raising frame that is convenient to adjust planting height comprises fixed frame 1, nutrient solution tray 2, planting tray 8 and liquid storage tank 10, and the inside of fixed frame 1 is equipped with nutrient solution tray 2, and fixed frame A slide rail 3 is installed on the inner wall of 1, and the edge of the nutrient solution tray 2 is embedded in the slide rail 3. The nutrient solution tray 2 can slide up and down along the slide rail 3. A lifting mechanism is installed under the nutrient solution tray 2. The lifting mechanism includes The positive and negative motor 4, the first two-way screw rod 5, the lifting slider 6 and the connecting rod 7, the side wall of the fixed frame 1 are fixedly connected with the positive and negative motor 4, and the shaft extension end of the positive and negative motor 4 is fixedly connected with the second A two-way screw rod 5, the end of the fir...

Embodiment 2

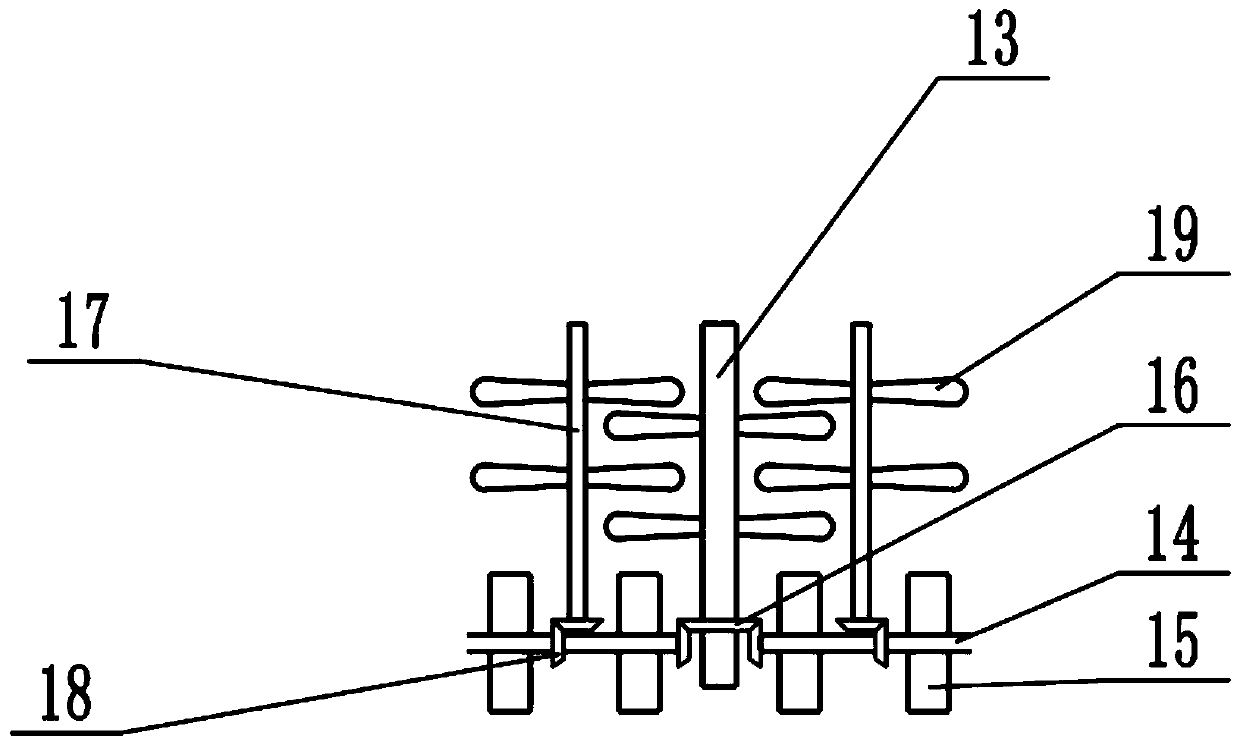

[0022] On the basis of Embodiment 1, a stirring mechanism is installed inside the liquid storage tank 10, and the stirring mechanism includes a stirring motor 12, a driving shaft 13, a driven shaft 14, a stirring plate 15, a stirring plate 15 and a first bevel gear set 16, The top of the liquid storage tank 10 is fixedly connected with a stirring motor 12, and the shaft extension end of the stirring motor 12 is fixedly connected with a driving shaft 13, and the driving shaft 13 extends into the liquid storage tank 10, and the two sides of the driving shaft 13 are respectively provided with driven shafts 14. One end of the driven shaft 14 is connected to the driving shaft 13 through the first bevel gear set 16, the other end of the driven shaft 14 is connected to the inner wall of the liquid storage tank 10 in rotation, and a stirring plate 15 is distributed on the driven shaft 14, Stirring motor 12 drives driving shaft 13 to rotate when running, and then drives driven shaft 14 ...

Embodiment 1、 Embodiment 2

[0023] In conjunction with Embodiment 1 and Embodiment 2, the working principle of the present invention is: the crop seedlings are planted in the planting groove 9, and the roots of the seedlings stretch out from the bottom of the planting groove 9, and are immersed in the nutrient solution in the nutrient solution tray 2 , the seedlings are cultivated, and the depths of the roots of the seedlings of different crops are different, start the forward and reverse motor 4, drive the first two-way screw mandrel 5 to rotate, drive the nutrient solution plate 2 to move up and down, and adjust the height of the nutrient solution plate 2, thereby Regulate the water entry depth of seedling roots according to actual needs, start the stirring motor 12, drive the driving shaft 13 to rotate, and then drive the driven shaft 14 to rotate through the first bevel gear set 16, utilize the stirring plate 15 to stir the nutrient solution, and drive the nutrient solution to tumbling upwards, Preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com