Uniform flow-guiding pyrolysis reaction device for urea and high-temperature flue gas

A technology of high temperature flue gas and reaction equipment, which is applied in the chemical method of reacting liquid and gas medium, the preparation/separation of ammonia, inorganic chemistry, etc. Reaction, reducing pyrolysis efficiency and other problems, to achieve the effect of enhancing urea pyrolysis effect and pyrolysis speed, avoiding the reduction of urea pyrolysis reaction efficiency, and increasing the spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

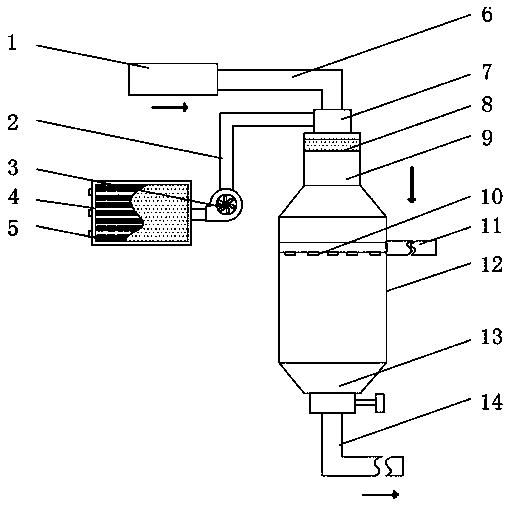

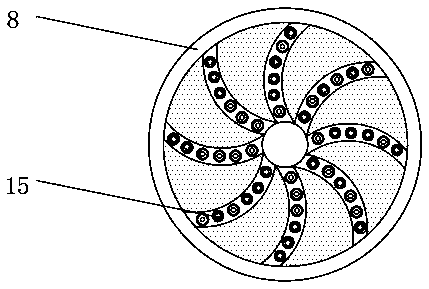

[0021] Embodiment one, by Figure 1-3 Given, the present invention includes a high-temperature flue gas inlet 1 and a pyrolysis reaction chamber 12, one side of the high-temperature flue gas inlet 1 is connected with a flue gas pipe 6, and one end of the flue gas pipe 6 is provided with a heating chamber 7, and the heating chamber 7 A diffusion section 9 is provided at the bottom, and the bottom of the diffusion section 9 is connected through the pyrolysis reaction chamber 12. A deflector 8 is installed inside the diffusion section 9, and a flue gas guide port 15 is provided on the surface of the deflector 8. The deflector 8 has a circular structure, and the thickness of the deflector 8 is 5-10 cm. There are a plurality of smoke guide ports 15, and the plurality of smoke guide ports 15 are distributed in a ring and equidistant.

[0022] Specifically, through the plurality of flue gas guide ports 15 on the circular deflector 8, the incoming flue gas can be effectively divided i...

Embodiment 2

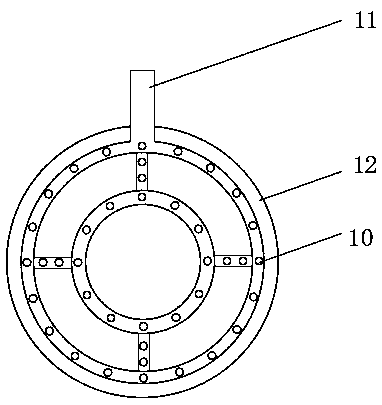

[0023] Embodiment 2, on the basis of Embodiment 1, one side of the pyrolysis reaction chamber 12 is provided with a urea atomization spray gun 11, and the urea atomization spray gun 11 extends to the inside of the pyrolysis reaction chamber 12, and the urea atomization Atomizing nozzles 10 are arranged on the surface of the spray gun 11, and there are a plurality of atomizing nozzles 10, and the plurality of atomizing nozzles 10 are distributed equidistantly in a ring.

[0024] Specifically, the surface of the annularly distributed urea atomizing spray gun 11 is equidistantly provided with a plurality of atomizing nozzles 10, which can effectively increase the spraying area of the urea solution, so that the pyrolysis reaction between the urea solution molecules and the high-temperature flue gas is more sufficient, The reaction efficiency of urea pyrolysis is improved.

Embodiment 3

[0025] Embodiment 3, on the basis of Embodiment 1, a heating device 4 is provided on one side of the pyrolysis reaction chamber 12, and a plurality of heating fins 5 are installed inside the heating device 4, and a suction device is installed on one side of the heating device 4. Fan 3, and one end of the suction fan 3 is equipped with an air guide pipe 2, and one end of the air guide pipe 2 is connected through the heating chamber 7, and one side of the heating device 4 is provided with an air inlet.

[0026] Specifically, heat is generated through the heating fins 5 inside the heating device 4, and under the adsorption of the suction fan 3, the heat inside the heating device 4 is guided into the inside of the heating chamber 7 through the air guide pipe 2, and the flue gas is guided. The heat lost in the process is supplemented by heat, so that the flue gas can have enough heat to enter the interior of the pyrolysis reaction chamber 12 to perform a sufficient pyrolysis reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap