Fiber bundle tension reducing mechanism for automatic fiber placing machine

A technology for automatic laying and tow, applied in the field of tow tension reduction mechanism of automatic laying machine, can solve the problems of reduced forming speed, fiber bridging, poor forming quality, etc., and achieve the effect of preventing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

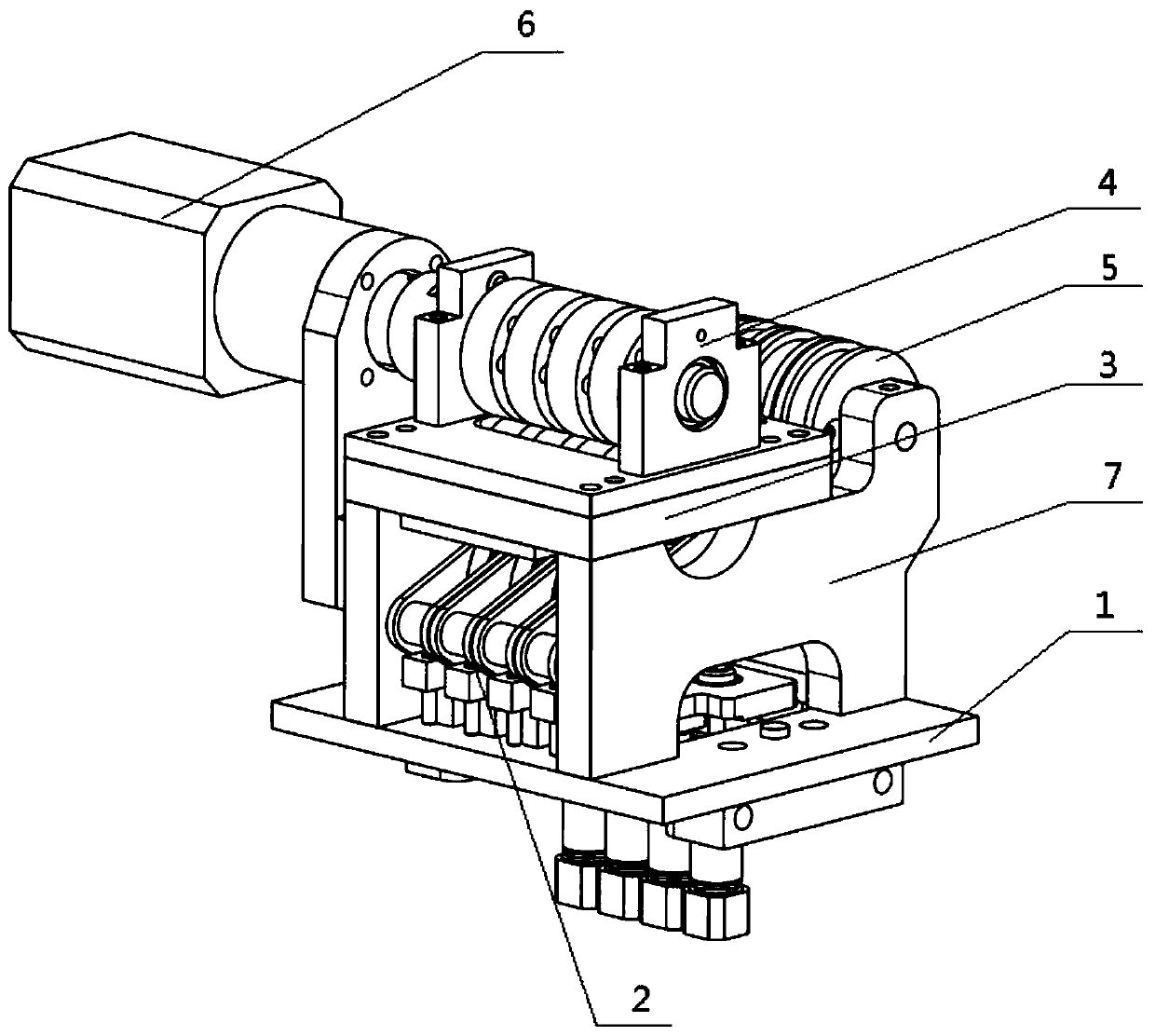

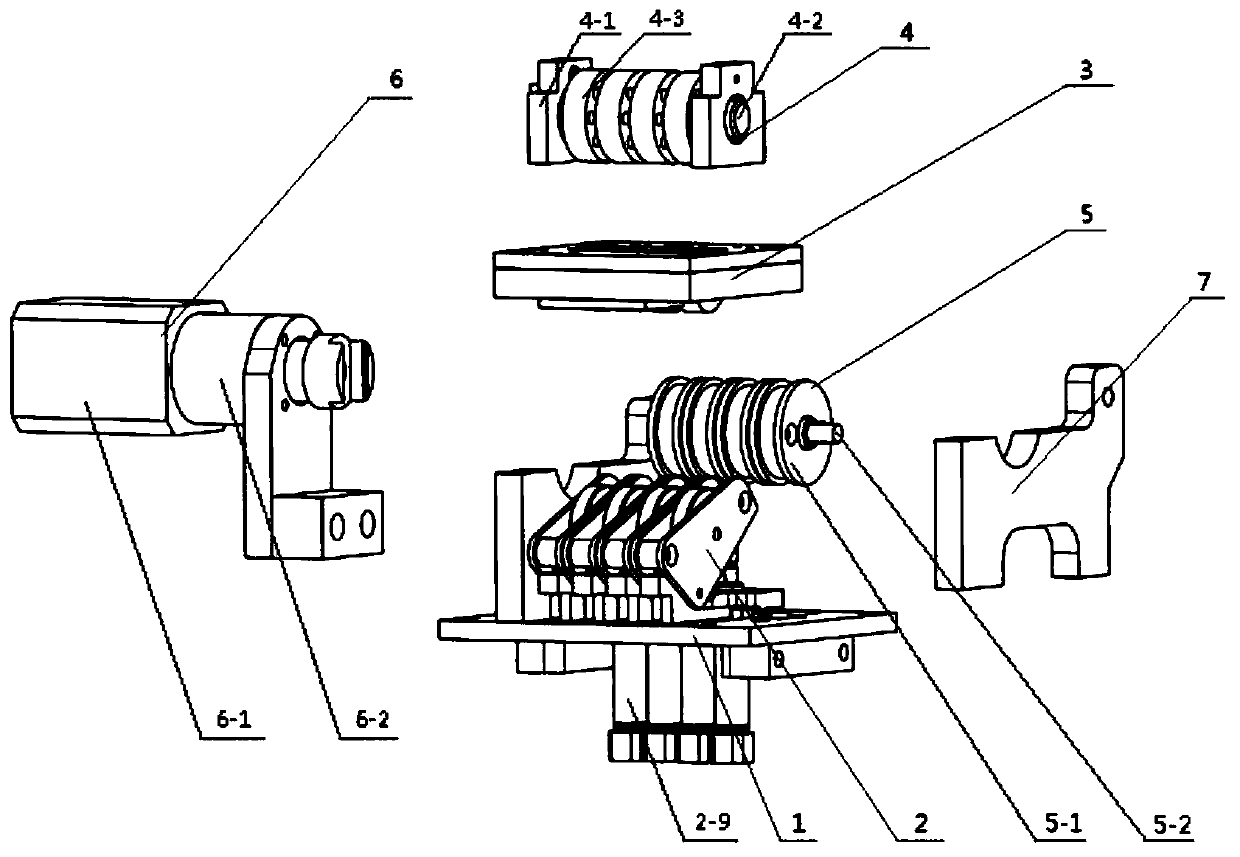

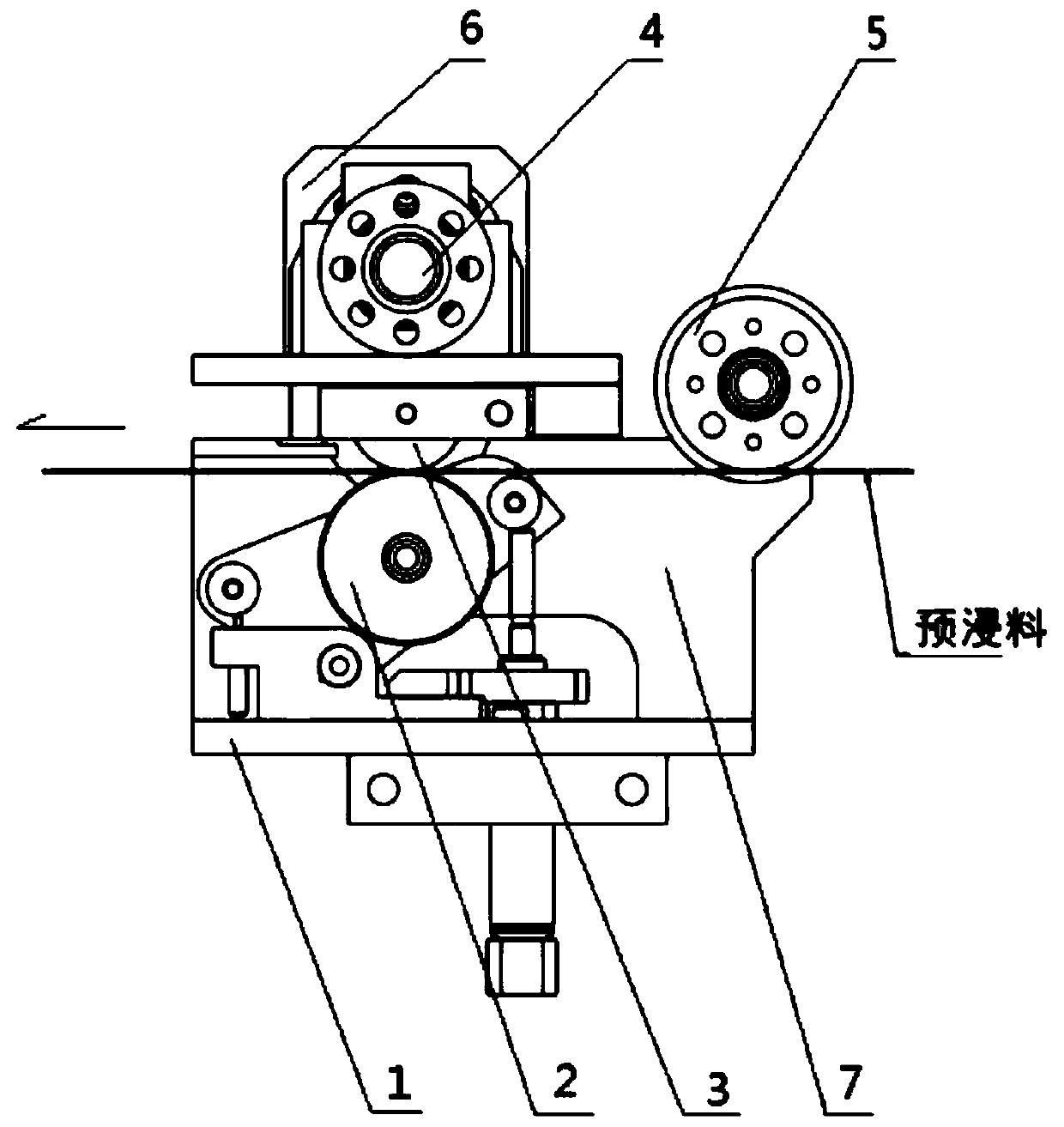

[0031] Embodiment one, combined with the attached figure 1 and 3 Explanation: a tow tension reduction mechanism of an automatic laying machine, including: a base 1, a yarn stop wheel assembly 2, an intermediate wheel assembly 3, a friction wheel assembly 4, a guide wheel assembly 5 and a tension reduction motor assembly 6,

[0032] The upper end surface of the base 1 is provided with a yarn stop wheel assembly 2, and both sides of the yarn stop wheel assembly 2 are provided with support plates 7, both ends of the guide wheel assembly 5 are connected with the support plate 7, and the upper end of the support plate 7 is equipped with an intermediate wheel assembly 3. The friction wheel assembly 4 is installed on the intermediate wheel assembly 3. The friction wheel assembly 4 is used in conjunction with the intermediate wheel assembly 3 for power transmission. The tension reduction motor assembly 6 is installed on the side wall of the support plate 7. The tension reduction motor...

Embodiment 2

[0033] Embodiment two: on the basis of embodiment one in conjunction with Figure 4To illustrate, the yarn stop wheel assembly 2 is a plurality of yarn stop wheel mechanisms connected side by side, and the yarn stop wheel mechanism includes: hinge support 2-1, hinge shaft 2-2, spring plunger 2-3, and yarn stop wheel 2 -4, one-way bearing 2-5, yarn stop cylinder support column 2-6, spring plunger support column 2-7 and mounting plate 2-8, hinge support 2-1 is installed on the base 1, hinge support The hinge shaft 2-2 is installed on the left and right side walls of the seat 2-1, and the both sides of the hinge support 2-1 are provided with a mounting plate 2-8, and the side walls of the mounting plate 2-8 are connected with the hinge shaft 2-2, and the mounting plate The middle part of 2-8 is equipped with a yarn stop wheel rotating shaft 2-10, and the yarn stop wheel 2-4 is installed on the yarn stop wheel rotating shaft 2-10 through a one-way bearing 2-5, and the two ends of ...

Embodiment 3

[0034] Embodiment three: on the basis of embodiment two in conjunction with figure 2 To illustrate, the guide wheel assembly 5 includes a guide wheel 5-1 and a guide shaft 5-2, the two ends of the guide shaft 5-2 are connected to the support plate 7, and the axis of the guide shaft 5-2 is connected to the yarn stop wheel shaft 2. The axes of -10 are parallel to each other, and the guide shaft 5-2 is equipped with a plurality of guide wheels 5-1, and the number of the guide wheels 5-1 is the same as that of the pressing wheels 2-4 and the positions are corresponding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com