Diesel propulsion system for double-engine, single-propeller and double-speed ratio ship

A propulsion system and single propeller technology, which is applied in ship propulsion, propulsion components, propulsion transmission devices, etc., can solve the problems of increased fuel and engine oil consumption, low diesel engine load, shortened service life, etc., to reduce fuel and engine oil Consumption law, improve operating conditions, prolong the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in conjunction with accompanying drawing and specific embodiment:

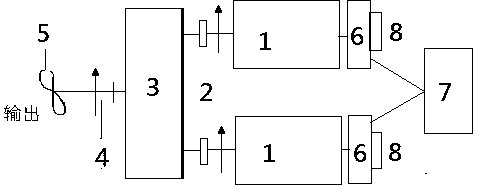

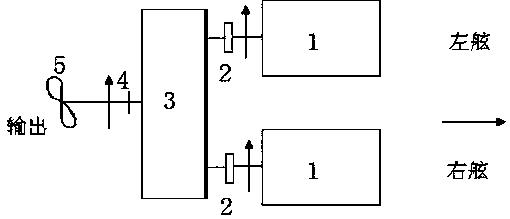

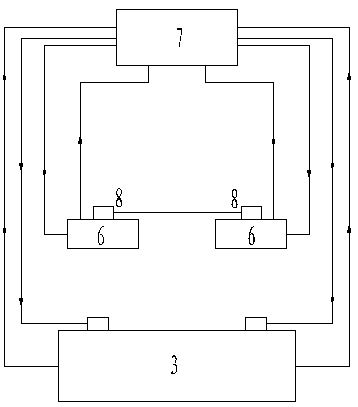

[0016] Such as figure 1 , figure 2 As shown, a marine diesel propulsion system with two engines, one propeller and two speed ratios, two diesel engines 1 of the system are connected with a gearbox 3 through a high-elastic coupling 2; the gearbox 3 of the system is driven by a tail shaft 4 Propeller 5 rotates; combined Figure 4 , the gearbox 3 has two input shafts respectively corresponding to the two diesel engines: the input shaft I9 and the input shaft II10; the input shaft I9 is provided with the same clutch I14 corresponding to the single engine operation of the diesel engine and the engine turning to the same The engines of two diesel engines run in parallel and the engines turn to the same clutch V17; the input shaft II10 is provided with the same clutch II15 for the diesel engines running alone and the same clutch VI19 for the engines running in parallel o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com