High-speed plate type bubble cap machine

A flat type, blister machine technology, applied in packaging machines, packaging, wrapping objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

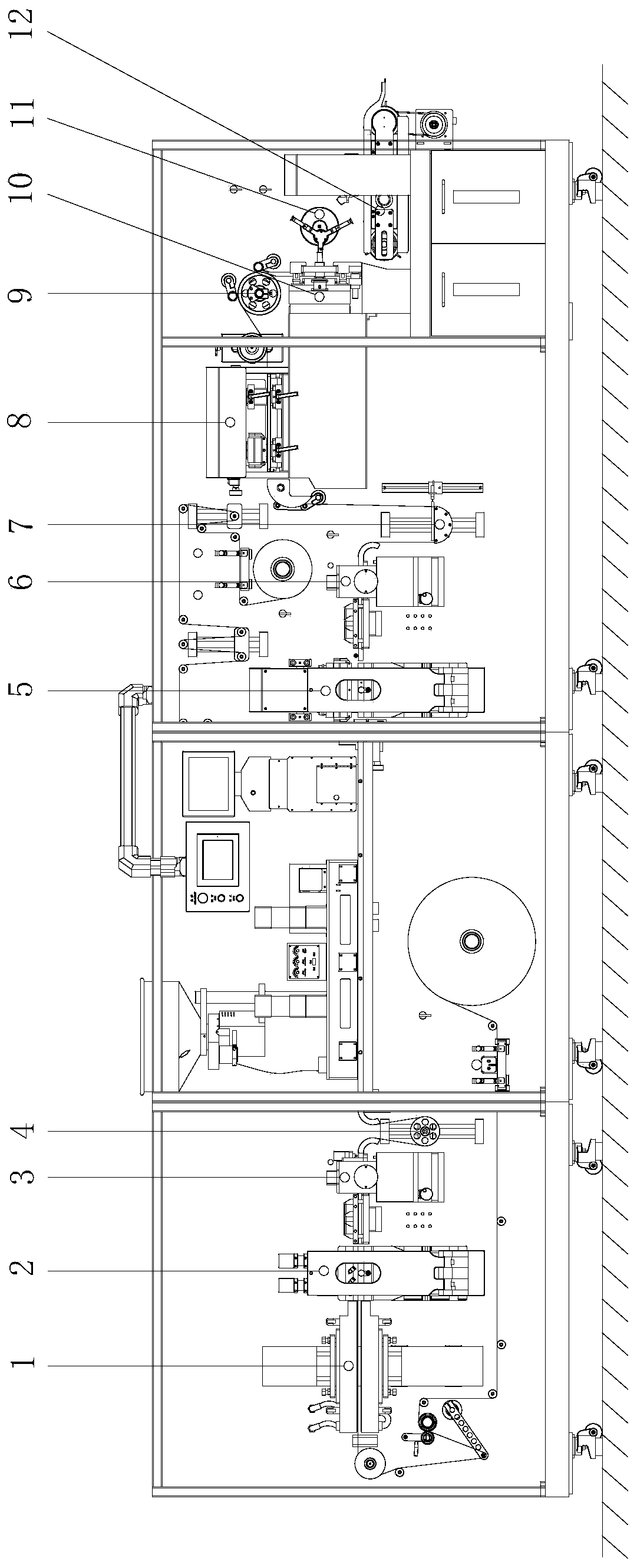

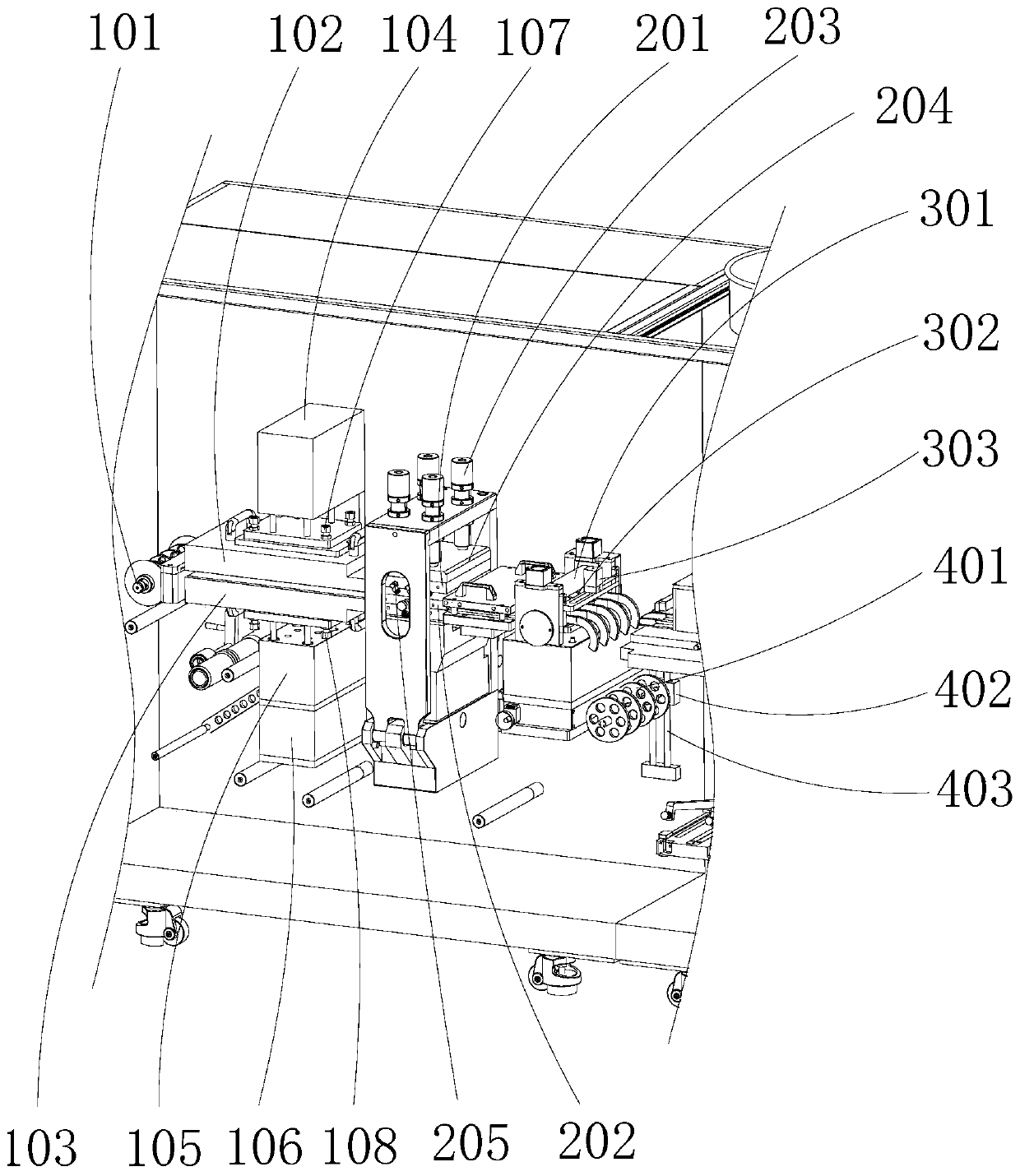

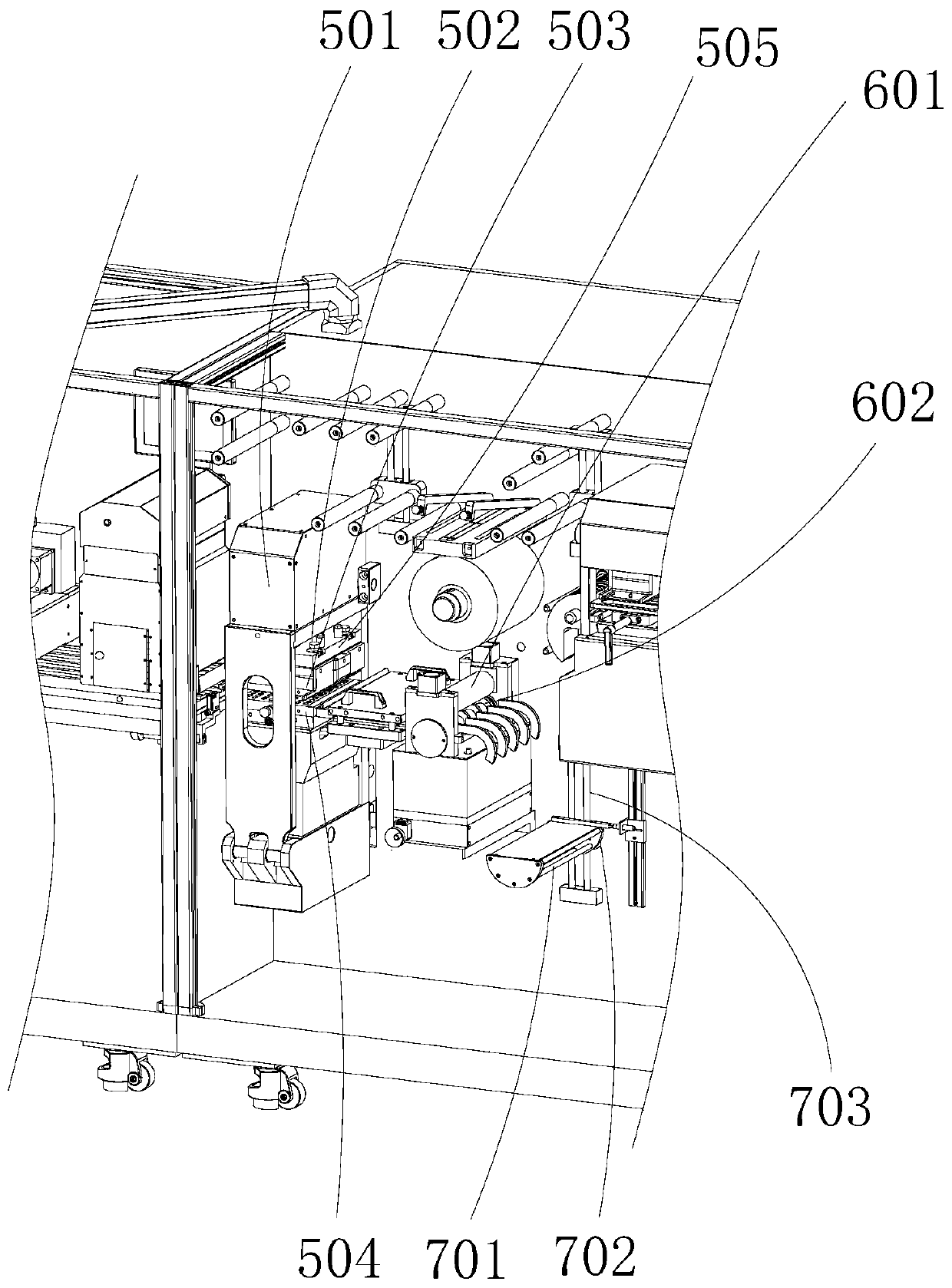

[0030] The present invention is a high-speed flat-plate blister machine, which has an innovative layout of the main station structure, such as figure 1 As shown, it includes a plastic sheet heating device 1, a forming station 2, a forming traction device 3, a forming storage device 4, a heat sealing station 5, a heat sealing traction device 6, a heat sealing storage device 7, and a batch number indentation station 8. Punching traction device 9 , punching station 10 , punching manipulator 11 , finished product conveying device 12 .

[0031] The various components of the present invention are arranged and connected according to the sequence of the process: plastic sheet heating device 1, forming station 2, forming traction device 3, forming material storage device 4, heat sealing station 5, heat sealing traction device 6, heat sealing storage material Device 7, batch number indentation station 8, punching traction device 9, punching station 10, finished product conveying device ...

Embodiment 2

[0048] In this embodiment, the mold layout method of the high-speed flat-type blister machine is 2 editions / time. The guide plate 815 is provided with two sets of guide plate guide posts 803 .

[0049] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com